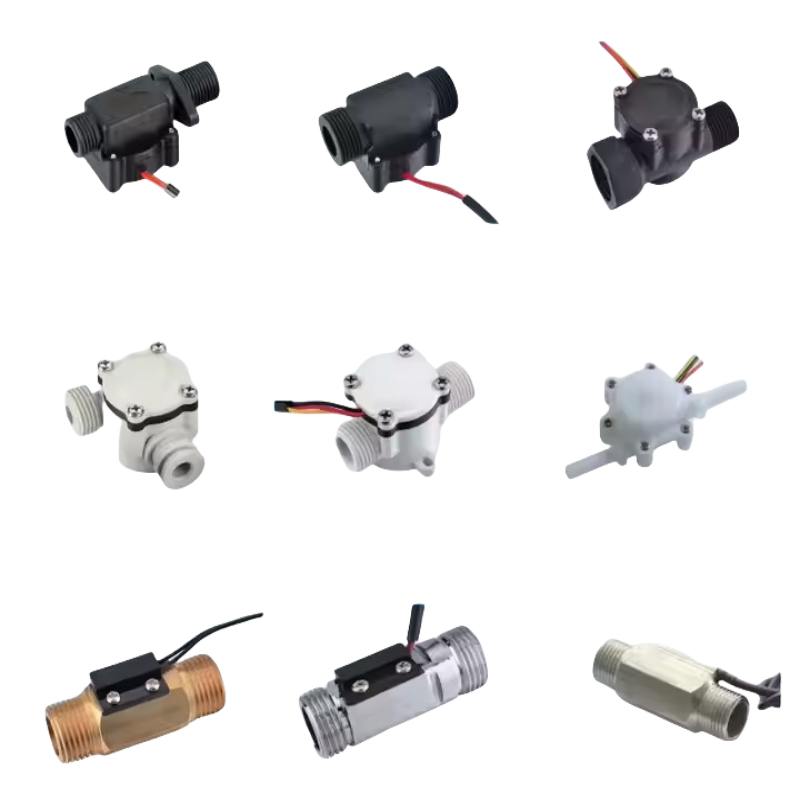

Water flow switches are critical components in countless industrial, commercial, and residential systems. These devices monitor liquid movement to ensure operational safety, efficiency, and reliability. In this blog, we’ll dive into the mechanics of water flow switches, their applications, and why choosing the right one—like the Plastic Magnetic Vertically Mount WFS04-G1/2” Flow Switch—can make all the difference.

What Is a Water Flow Switch?

A water flow switch is an electromechanical device that detects the presence, absence, or rate of liquid flow in a pipeline. When flow reaches a preset threshold (e.g., 1.5L/min), the switch triggers actions like activating alarms, shutting down pumps, or starting heaters.

Key Components:

- Magnetic Reed Sensor: Detects flow via a magnetically actuated piston or paddle.

- Contacts (N.O/N.C): Opens or closes circuits based on flow status.

- Housing Material: PP (polypropylene), POM (polyoxymethylene), or other corrosion-resistant plastics.

How Does a Magnetic Flow Switch Work?

The WFS04-G1/2” Vertical Mount Flow Switch operates on a simple yet reliable principle:

- Flow Activation: Liquid passes through the pipe, moving an internal magnetic piston.

- Magnetic Trigger: The piston’s magnet activates a reed sensor, changing the contact state (N.O to closed or N.C to open).

- Signal Output: The switch sends a signal to controllers, pumps, or alarms.

Why Vertical Mounting Matters:

Vertical installation minimizes debris buildup, ensuring accurate detection in low-flow scenarios (1.5–30L/min).

Top Applications of Water Flow Switches

- Industrial Equipment: Protect pumps and compressors from dry running.

- Automotive/Cooling Systems: Monitor coolant flow in engines or battery thermal management.

- Humidifiers & HVAC: Prevent damage from blocked water supply.

- Oil/Lubrication Systems: Ensure consistent oil flow in machinery.

Case Study: A Canadian auto manufacturer reduced pump failures by 40% after installing WFS04 switches in their coolant lines.

5 Reasons to Choose the WFS04-G1/2” Flow Switch

- Precision in Low Flow: Detects flow rates as low as 1.5L/min, ideal for sensitive systems.

- Durability: PP/POM housing resists oil, water, and temperatures up to 120°C (248°F).

- Smart Integration: Compatible with 100–220VDC systems and customizable wire lengths (350mm+).

- Easy Maintenance: Vertical design reduces clogging risks.

- Cost-Effective: Prevents costly equipment damage and downtime.

Installation Tips & Best Practices

- Mounting: Install vertically in straight pipe sections (10x pipe diameter from bends).

- Calibration: Adjust the flow rate threshold using the built-in adjustment screw.

- Testing: Simulate flow conditions to verify N.O/N.C contact responses.

Conclusion

Water flow switches like the WFS04-G1/2” are unsung heroes in fluid-dependent systems. By combining rugged materials, smart design, and precise detection, they safeguard operations across industries. Whether you’re managing a car factory or a commercial HVAC system, investing in a high-quality flow switch ensures your equipment runs smoothly—drop by drop.

Need a flow switch tailored to your specs? Contact us for custom wire lengths, materials, or voltage configurations!