Properly wiring an automatic water tank level switch is critical for ensuring reliable liquid level monitoring and control. Whether you’re managing industrial reservoirs, commercial water systems, or agricultural storage tanks, a well-installed float switch safeguards against overflows, dry runs, and equipment damage. This guide walks you through the process of connecting an Automatic Plastic Water Tank Level Switch – IP67 Electric Liquid Float Sensor to your control panel, emphasizing safety, efficiency, and compliance.

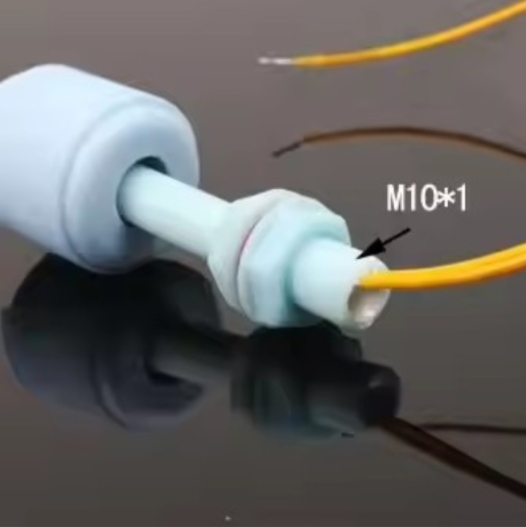

The Automatic Plastic Water Tank Level Switch – IP67 Electric Liquid Float Sensor is designed for precision and durability. Key features include:

– IP67 waterproof housing for resistance to dust, moisture, and harsh environments.

– Magnetic reed switch with NO/NC (normally open/normally closed) contacts for flexible signal output.

– PP material construction and vertical mounting, compatible with temperatures from -10°C to +85°C.

– CE/ROHS/REACH certifications, ensuring compliance with international safety standards.

This sensor is ideal for integration with pumps, alarms, and automation systems, providing real-time liquid level data to your control panel.

Step 1: Pre-Installation Preparation

Tools Required:

– Screwdrivers (flathead and Phillips).

– Wire strippers and crimping tools.

– Multimeter for continuity testing.

– UL-listed electrical cables (rated for 200VDC/1.5A).

Safety First:

– Disconnect power to the control panel and pump system.

– Verify that the tank is empty or at a safe level for installation.

Step 2: Mounting the Float Sensor

1. Positioning:

– Attach the sensor vertically to the tank wall using mounting brackets. Ensure the float moves freely without obstructions.

– For multi-level control, install additional sensors at different heights.

2. Sealing:

– Tighten the IP67-rated gland nut to secure the cable entry point, preventing water ingress.

Step 3: Wiring the Sensor to the Control Panel

1. Identify Contacts:

– Locate the NO (normally open) and NC (normally closed) terminals on the sensor.

– For pump control, NO contacts trigger activation when the liquid rises; NC contacts signal low-level alerts.

2. Connect Wires:

– Strip 6-8mm of insulation from the sensor’s cables.

– Link the NO/NC wires to the control panel’s input terminals (refer to your panel’s manual for specific terminals).

– Ground the sensor’s earth wire to the panel’s grounding point.

3. Secure Connections:

– Use crimp connectors or terminal blocks to prevent loose wires.

– Apply dielectric grease to exposed metal parts to reduce corrosion.

Step 4: Testing and Calibration

1. Power On:

– Reconnect the control panel’s power supply.

– Simulate liquid levels by manually lifting or lowering the float.

2. Verify Signals:

– Use a multimeter to confirm that the NO/NC contacts open/close as expected.

– Check the control panel’s display or indicator lights for proper response.

3. Adjust Sensitivity:

– If your system supports it, fine-tune alarm or pump activation thresholds via the panel’s software.

Step 5: Maintenance and Troubleshooting

– Monthly Checks: Inspect cables for wear, corrosion, or rodent damage. Clean the float of debris.

– Annual Calibration: Re-test continuity and signal accuracy.

– Common Issues:

– False signals: Ensure the float isn’t stuck and the magnetic reed switch is intact.

– No power: Verify connections and replace damaged cables.

Why Choose the Automatic Plastic Water Tank Level Switch?

The Automatic Plastic Water Tank Level Switch – IP67 Electric Liquid Float Sensor simplifies liquid management with its rugged design and plug-and-play compatibility. Its magnetic reed switch ensures precise, drift-free signaling, while the IP67 rating guarantees reliability in demanding environments.

Optimize Your Liquid Control System Today

For seamless integration of automatic water tank level switches into your operations, trust a sensor built for accuracy and longevity. Visit our website to explore technical specifications, compliance details, and bulk pricing options—or contact our engineering team for personalized wiring diagrams and installation support.