In industrial environments where liquid level monitoring demands precision and durability, the Flygt ENM 10 Magnetic Float Switch stands out as a robust, intelligent solution. Engineered for harsh applications—from chemical storage tanks to automotive reservoirs—this sensor combines corrosion-resistant materials, smart switching logic, and seamless integration capabilities to optimize operational safety and efficiency.

Core Features & Technical Specifications

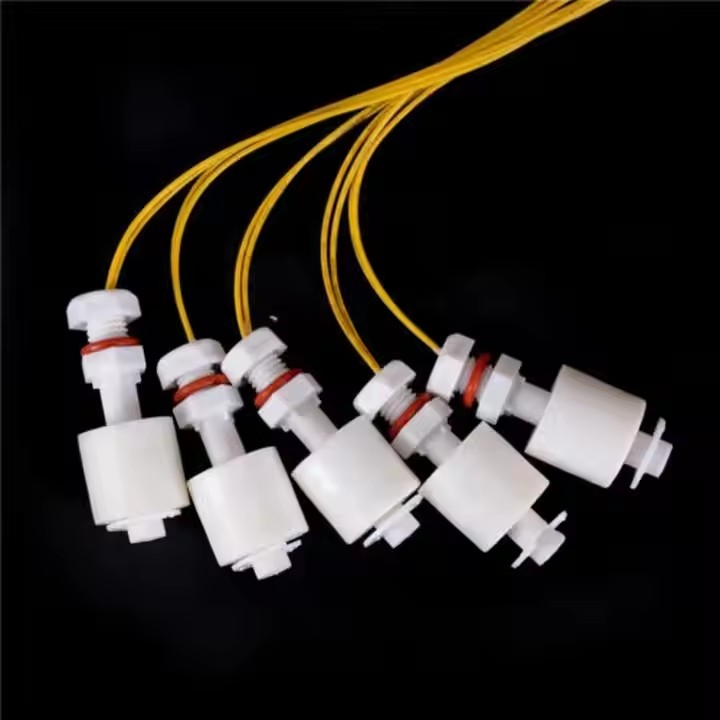

Robust Construction

- Material: SUS 304/316 stainless steel ensures resistance to corrosive liquids and high-temperature extremes (-40°C to +120°C)

- IP67 Protection: Dust-tight and waterproof design for reliable performance in submerged or dusty conditions

Intelligent Switching & Performance

- N.O/N.C Contacts: Configurable logic prevents overfill, dry-run risks, or leakage by triggering alarms, pumps, or automation systems

- High Load Capacity: Rated for 1.5A/200VDC (10W/50W), compatible with industrial control panels and PLCs

Precision Detection

- Magnetic Float Mechanism: 400mm sensor body enables hysteresis-free level detection with a 13-meter cable (standard), adaptable to vertical/horizontal mounting

- Liquid Compatibility: Optimized for fluids with specific gravity 0.95–1.10 g/cm³; custom cable lengths (e.g., 20m) available for non-standard applications

Key Applications

- Chemical & Petroleum Tanks: Monitors acid/alkali levels to prevent overflow or pump cavitation

- Water Treatment Systems: Automates pump control in sewage stations or drainage pools for stable liquid management

- Industrial Reservoirs: Integrates with SCADA systems for real-time level alerts in automotive coolant or hydraulic oil storage

Why Choose the Flygt ENM 10?

- Low Maintenance: Corrosion-resistant materials and a tangle-free float design minimize downtime

- Longevity: Proven operational reliability in extreme conditions, validated by industry stress tests

- Easy Integration: Plug-and-play installation with adjustable cable lengths for flexible threshold settings