In the core of industrial operations, where productivity and safety are governed by the reliability of every component, the choice of a control interface is never trivial. For engineers specifying parts for motor control panels, heavy machinery, or outdoor installations, a standard push button is insufficient. The environment demands more. It requires a component engineered to endure. The 22mm waterproof metal push button switch is precisely that—a high-current, robustly sealed solution designed to execute critical start-stop commands with unwavering certainty. Its design converges on three pivotal engineering principles: the strength to handle substantial electrical loads directly, the flexibility offered by a dual-contact configuration, and the practical intelligence of a pre-wired design for seamless integration. This exploration details how this switch transforms from a simple component into a cornerstone of reliable system design across multiple demanding sectors.

In the core of industrial operations, where productivity and safety are governed by the reliability of every component, the choice of a control interface is never trivial. For engineers specifying parts for motor control panels, heavy machinery, or outdoor installations, a standard push button is insufficient. The environment demands more. It requires a component engineered to endure. The 22mm waterproof metal push button switch is precisely that—a high-current, robustly sealed solution designed to execute critical start-stop commands with unwavering certainty. Its design converges on three pivotal engineering principles: the strength to handle substantial electrical loads directly, the flexibility offered by a dual-contact configuration, and the practical intelligence of a pre-wired design for seamless integration. This exploration details how this switch transforms from a simple component into a cornerstone of reliable system design across multiple demanding sectors.

Engineered for Certainty: Core Design and Technical Specifications

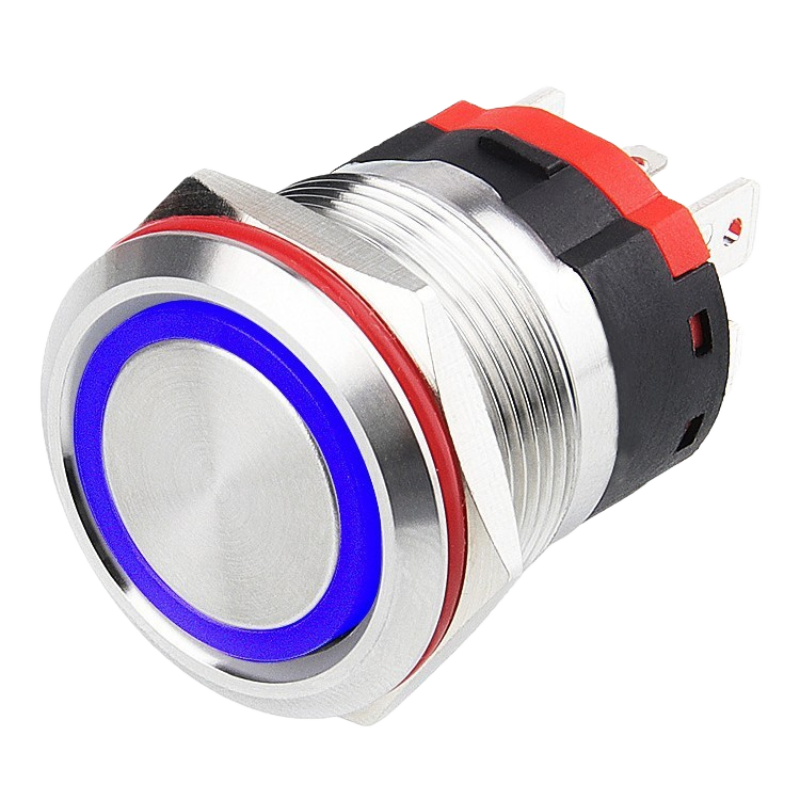

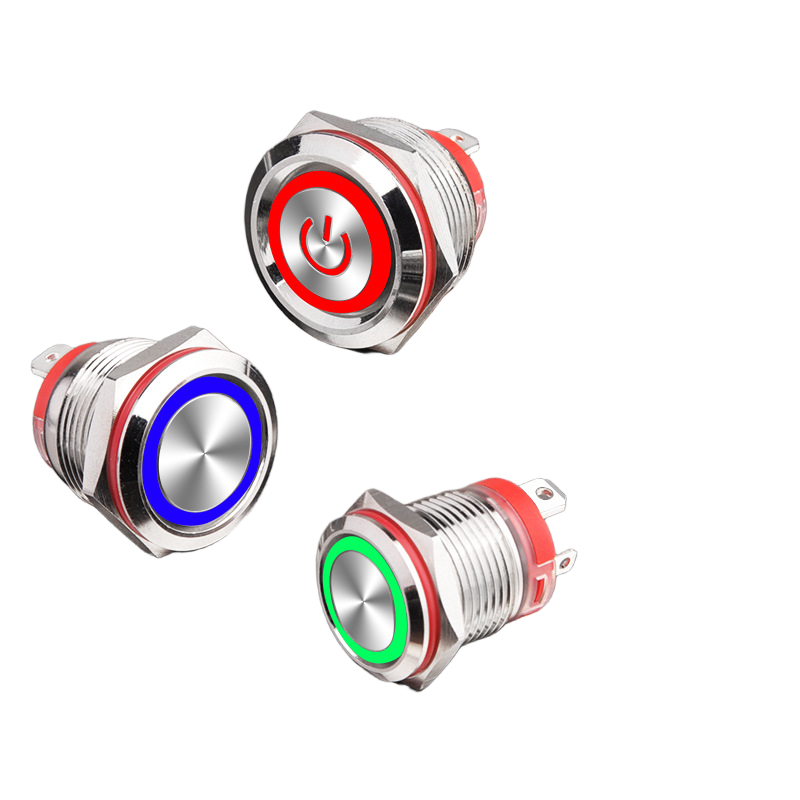

Reliability begins with construction. The housing of this switch is crafted from durable metal, offering superior resistance to impact, corrosion, and daily wear. This isn’t merely about longevity; it’s about maintaining integrity in environments filled with vibration, chemical exposure, or physical stress. The defining feature is its high-grade waterproof and dustproof seal, typically meeting IP65 or IP67 standards. This protection ensures consistent performance whether facing washdowns in a food plant, humidity in a marine application, or dust in a mining operation.

The electrical heart of the component is its high-current rating. This capability allows the switch to directly control motors, pumps, solenoids, or heating elements without always necessitating an intermediate relay. This direct control simplifies panel design, reduces potential failure points, and can lower overall system cost. The 2NO (Two Normally Open) contact configuration is a critical feature for advanced control. It provides circuit flexibility and functional redundancy. One circuit can manage the main power load for starting a conveyor motor, while the parallel circuit can simultaneously illuminate a “Running” indicator, send a confirmation signal to a PLC, or energize a safety interlock. This dual-signal capability is fundamental for creating intelligent, safe, and observable control systems.

The pre-wired design represents a significant shift from traditional installation hurdles. Arriving with a connected, sealed cable and connector, it eliminates time-consuming and error-prone field wiring inside crowded control cabinets. Technicians can deploy or replace these switches rapidly, drastically reducing machine assembly time or maintenance downtime. This practical feature translates the switch’s engineering quality directly into cost savings and operational efficiency.

Proven in the Field: Diverse Industrial Application Scenarios

The true measure of this switch’s value is its performance in real-world applications. Its versatility makes it a preferred component across industries where control must be both powerful and dependable.

Industrial Automation & Manufacturing: On the factory floor, this switch serves as the primary local control for machine start-up, cycle initiation, or manual jogging functions. Its sealed body protects against coolant mist and metal particulate. The high-current contacts reliably power motor starters, while the auxiliary 2NO circuit provides essential feedback to the factory’s control network, signaling the machine’s operational status.

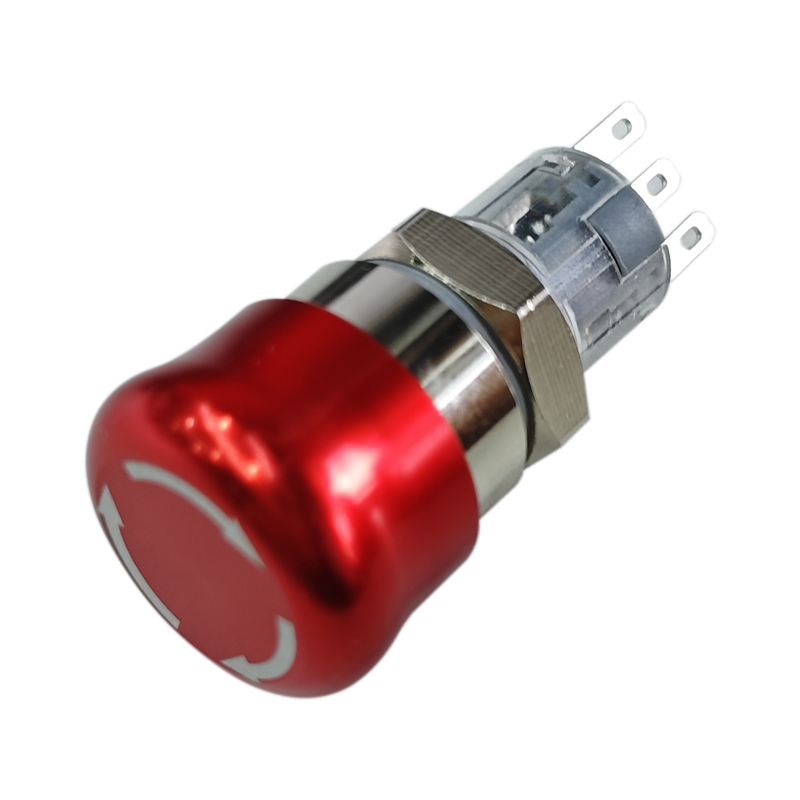

Material Handling & Heavy Equipment: For conveyor systems, packaging lines, or industrial lifts, reliable start-stop control is non-negotiable. The switch’s rugged metal construction withstands the constant vibration and occasional impacts of these environments. Installed as a control station on heavy machinery like crushers or balers, its tactile feedback is discernible even through work gloves, and its pre-wired nature allows for quick service or repositioning.

Infrastructure & Utilities: In pump control panels for water treatment, ventilation systems in parking garages, or generator set interfaces, equipment often resides in damp, dirty, or outdoor enclosures. The waterproof sealing ensures long-term reliability despite humidity and condensation. Here, the switch acts as the decisive human command point for critical infrastructure, with its durability minimizing life-cycle maintenance.

Mobile & Harsh Environment Applications: From agricultural tractors and construction vehicles to marine deck equipment, controls face extreme conditions. Temperature swings, moisture, UV exposure, and constant vibration test every component. This switch is built for this challenge, providing dependable power control for winches, spreaders, or auxiliary systems where failure is not an option.

Strategic Advantages: The Business Case for a Superior Component

Specifying this 22mm push button switch extends benefits beyond its technical datasheet. For Original Equipment Manufacturers (OEMs), it contributes to a more robust and marketable end product. The integrated features—high current, dual contacts, and sealing—often consolidate multiple components (a switch, an indicator light, a separate seal) into one, simplifying the bill of materials and assembly process. The reliability inherently reduces potential warranty claims and field service calls, protecting brand reputation.

From a system designer’s perspective, the flexibility of the 2NO contact opens doors for more elegant and safe control schemes without adding complexity. The pre-wired feature is a direct contributor to lower total installed cost, saving valuable engineering hours in both design and field deployment. Furthermore, the professional aesthetic and positive tactile action of a metal switch enhance the perceived quality and user experience of the final equipment, a subtle but powerful differentiator.

Conclusion: Building Unshakeable Control with a Foundational Component

In sectors where operational continuity and safety are paramount, control components must be selected not as commodities, but as strategic assets. The 22mm waterproof metal push button switch, with its high-current capacity, versatile 2NO contact configuration, and user-centric pre-wired design, represents a comprehensive answer to the demands of modern industrial control. It is engineered to perform consistently where other components might falter, ensuring that the critical command to start or stop a process is always delivered with certainty.

For engineers, facility managers, and equipment builders who prioritize durability, simplicity, and long-term value, this switch offers a reliable foundation. It is a component that bridges the gap between human intention and machine action with robust precision.