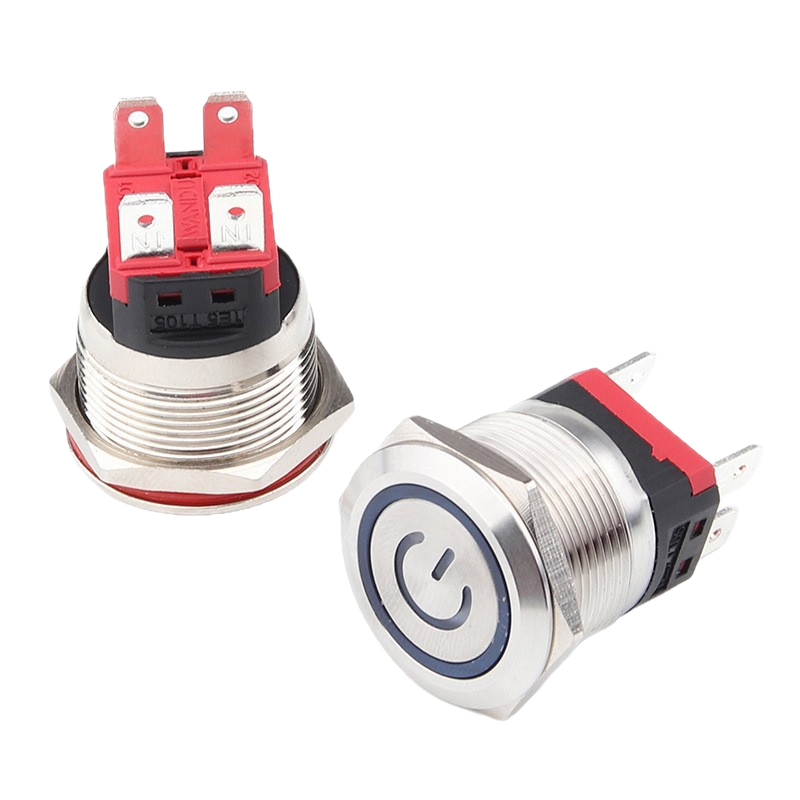

In the world of industrial design and rugged equipment, space is at a premium, and reliability is non-negotiable. When your control panels demand high-current switching in harsh environments, the 16/19/22mm 20A High Current Short-Body Metal Push Button Switch emerges as the definitive solution. This comprehensive guide explores why this compact, robust component is revolutionizing panels in automation, marine, heavy machinery, and energy sectors.

In the world of industrial design and rugged equipment, space is at a premium, and reliability is non-negotiable. When your control panels demand high-current switching in harsh environments, the 16/19/22mm 20A High Current Short-Body Metal Push Button Switch emerges as the definitive solution. This comprehensive guide explores why this compact, robust component is revolutionizing panels in automation, marine, heavy machinery, and energy sectors.

The Core Challenge: Power, Protection, and Real Estate

Design engineers constantly face the triad of challenges:

High Current Demand: Switching inductive loads like motors, solenoids, or heaters requires components rated for 15-20A at 250VAC.

Environmental Harshness: Exposure to moisture, dust, chemicals, and physical impact is a daily reality.

Space Constraints: Panel depth is limited, but functionality cannot be compromised.

Traditional switches often force a compromise. Bulkier bodies eat up panel depth, while plastic housings or lower IP ratings fail in demanding conditions. This is where the engineered superiority of the short-body, high-current metal switch becomes apparent.

Engineering Deep Dive: Anatomy of Reliability

1. The Short-Body Design Advantage

The reduced rear-panel depth is not merely a convenience—it’s a critical design enabler.

Space Optimization: Allows for installation in shallow enclosures, control boxes, and modular panels where every millimeter counts.

Improved Wiring: Provides more space for wire management and bending radii behind the panel, enhancing safety and serviceability.

Heat Dissipation: The metal body acts as a heat sink, efficiently drawing heat away from the high-current contacts, contributing to longevity.

2. Uncompromising 20A Performance

The 20A/250VAC rating (typically per IEC/EN 60947-5-1 standards for AC-15 duty) is the cornerstone of this switch. This is achieved through:

Silver-Tin Oxide (AgSnO₂) Contacts: Superior to standard silver-cadmium, these contacts offer excellent resistance to welding and arc erosion under high inductive loads, ensuring stable contact resistance and extended electrical life.

Robust Internal Spring Mechanism: Designed to provide consistent contact pressure and reliable snap-action, even after millions of mechanical cycles.

3. Rugged Metal Housing & Superior Sealing

Housing Materials: Options typically include brass with nickel plating for excellent corrosion resistance or stainless steel (SUS304) for maximum strength and chemical resistance in extreme environments.

Waterproof Protection: Sealing is achieved through precision-molded silicone gaskets at the front bezel and a gland seal at the rear. Standard ratings are IP65 (dust-tight, jet-proof), with IP67 (immersion-proof) or even IP69K (high-pressure washdown) often available. This makes the switch ideal for food processing, marine decks, and outdoor machinery.

4. Maintained or Momentary Action

The availability of both Maintained (Latching) and Momentary (Self-Resetting/Push-to-Make) actions in the same footprint offers ultimate design flexibility.

Maintained (Self-Locking): Perfect for power ON/OFF functions, mode selection, or any state that needs to be held without continuous operator input.

Momentary: Essential for start/stop controls, jog functions, or safety interlocks that require a spring return.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Mounting Hole Diameter | 16mm, 19mm, 22mm (Industry-standard cutouts) |

| Electrical Rating | 20A @ 250VAC (AC-15), 10A @ 24VDC (DC-13) |

| Contact Material | AgSnO₂ (Silver Tin Oxide) Alloy |

| Housing Material | Nickel-Plated Brass / Stainless Steel (SUS304) |

| Ingress Protection | IP65 (Standard), IP67/IP69K (Optional) |

| Operating Temperature | -25°C to +85°C (Extended ranges available) |

| Mechanical Life | >1,000,000 cycles |

| Electrical Life | >100,000 cycles at rated load |

| Actuation Force | ~3.5N ± 1N (Customizable) |

Direct Application Scenarios

Industrial Automation: Main control panels for CNC machines, presses, and robotic cells requiring washdown.

Marine & RV: Engine start/stop, bilge pump controls, and navigation system panels.

Heavy Equipment: Excavator, tractor, and agricultural machinery consoles exposed to dust and rain.

Energy & Infrastructure: Control switches for generator sets, pump stations, and telecom shelters.

Selection & Sourcing Checklist for Engineers

When specifying this switch, ensure your supplier confirms:

Certifications: Compliance with relevant international standards (CE, UL, RoHS).

Termination Options: Screw terminals, solder lugs, or PCB pins to match your assembly process.

Seal Material Compatibility: For applications involving oils or aggressive chemicals.

Customization: Availability of specific actuator colors, engraved legends, or illuminated versions.

Conclusion: The Smart Choice for Demanding Designs

The 16/19/22mm 20A High Current Short-Body Metal Push Button Switch is more than a component—it’s a strategic design decision. It eliminates the traditional trade-off between current capacity, environmental resilience, and space. By choosing this engineered solution, you invest in panel reliability, reduce long-term maintenance costs, and enable more compact, professional, and durable end products.

Ready to power your next design with reliability? Contact our engineering team today for detailed CAD models, test reports, and custom configuration support. Let us help you integrate this compact powerhouse into your application.