In the world of industrial and commercial equipment, the oxidized black metal push button switch stands out as a versatile and reliable component. With its sleek appearance and robust construction, this switch is becoming an increasingly popular choice for a wide range of applications.

In the world of industrial and commercial equipment, the oxidized black metal push button switch stands out as a versatile and reliable component. With its sleek appearance and robust construction, this switch is becoming an increasingly popular choice for a wide range of applications.

Unmatched Durability

The oxidized black finish not only gives the switch a modern and professional look but also provides exceptional resistance to corrosion and wear. This makes it ideal for harsh environments where exposure to moisture, dust, and chemicals is common. Whether we use it in outdoor equipment, marine applications, or industrial machinery, this switch can withstand the toughest conditions.

Versatile Specifications

One of the key advantages of the oxidized black metal push button switch is its versatility. It comes in a variety of mounting hole diameters, ranging from 16mm to 30mm, allowing it to fit into different designs and spaces. The switch can handle a wide range of voltages from 1.5V to 250V AC/DC, making it suitable for both low and high-power applications.

The rated current for resistive loads can reach up to 15A at 250V AC, while for inductive loads, it can handle up to 4A at 250V AC. This high current rating ensures that the switch can manage demanding electrical loads without failure. Additionally, the switch offers both self-locking and self-resetting options, providing flexibility in using.

How to assemble?

To properly install an oxidized black metal push button switch, follow these steps:

1. Preparation:

- Ensure you have all the necessary tools and materials, including the push button switch, wires, soldering iron (if needed), screwdrivers, and any mounting hardware provided with the switch.

- Turn off the power supply to the circuit where you’ll be installing the switch to avoid any electrical hazards.

2. Determine Mounting Location:

- Choose a suitable location for the switch that allows for easy access and operation. Consider the size of the switch and the mounting hole diameter required.

- Mark the position of the mounting hole on the panel or enclosure where the switch we will install.

3. Create Mounting Hole:

- Use an appropriate drill bit to create a hole in the panel or enclosure at the marked position. Ensure the hole size matches the mounting hole diameter of the switch.

- Deburr the edges of the hole to prevent any sharp edges from damaging the switch or wires.

4. Install the Switch:

- Insert the push button switch into the mounting hole from the front side of the panel or enclosure.

- Secure the switch in place using the provided mounting hardware, such as nuts and washers. Tighten the nuts to ensure the switch is firmly held in position, but avoid over-tightening to prevent damage.

5. Connect Wires:

- Identify the terminals on the back of the switch. These may be labeled or color-coded to indicate their function (e.g., common, normally open, normally closed).

- Strip the ends of the wires to the appropriate length and connect them to the corresponding terminals on the switch. You can use soldering or wire connectors to make secure connections.

- Ensure that the wires are connected according to the circuit diagram or requirements of your application.

6. Test the Switch:

- Once the wires are connected, double-check all connections to ensure they are secure and there are no loose wires.

- Turn on the power supply to the circuit and test the switch to verify that it operates correctly. Press the button to check if the desired action occurs, such as turning on a light or activating a device.

7. Final Assembly:

- If the switch has a cover or cap, install it according to the manufacturer’s instructions.

- Reassemble any parts of the panel or enclosure that were removed during the installation process.

By following these steps, you can ensure a proper and safe installation of the oxidized black metal push button switch.

Enhanced Safety and Reliability

Safety is paramount in any electrical application, and this switch doesn’t disappoint. It features an IP65 waterproof rating at the end of the button, with an optional IP67 rating, protecting it from water ingress and dust. The operating temperature range of -30°C to 85°C ensures that the switch performs reliably in extreme temperatures.

The switch also has a high dielectric strength of 2100MΩ at 500V DC/h and a compressive strength of 2500V AC at 20mA/min between pins and housings, further enhancing its safety and reliability. The silver tin oxide alloy contacts provide low contact resistance, ensuring efficient electrical conduction and long service life.

Aesthetic Appeal

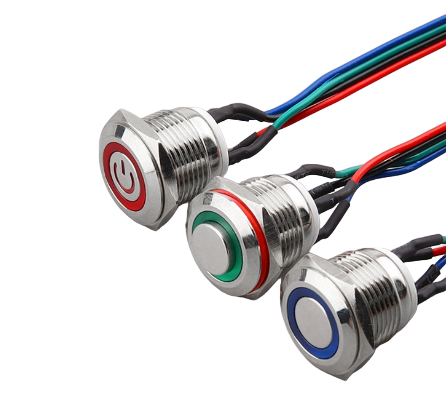

Beyond its functional benefits, the oxidized black metal push button switch also adds a touch of elegance to any device or equipment. The black finish is available in a matte or glossy option, allowing you to choose the one that best suits your design aesthetic. It can be paired with different glowing colors for the built-in LED, such as red, green, blue, yellow, or white, to create a visually appealing indicator.

Conclusion

For B2B customers looking for a durable, versatile, and reliable push button switch, the oxidized black metal push button switch is an excellent choice. Its combination of robust construction, high specifications, enhanced safety features, and aesthetic appeal makes it suitable for a wide range of industrial and commercial applications. Whether you’re designing new equipment or upgrading existing systems, this switch is sure to meet your needs and exceed your expectations.

In the world of industrial and commercial equipment,

In the world of industrial and commercial equipment,