In modern industrial operations, equipment failure carries a severe cost. Consequently, every component choice must prioritize absolute reliability. This is especially true for the human-machine interface. Therefore, selecting a control switch becomes a critical engineering decision. It directly impacts safety, productivity, and total cost of ownership. This blog provides a detailed analysis of a premier solution: the Self-Locking Waterproof Metal Push Button Switch. Specifically, we examine the 16mm model with stainless steel housing and gold-plated pins. Furthermore, we will explore its technical advantages and industry applications. Ultimately, this knowledge empowers you to specify components that enhance product longevity and build client trust.

In modern industrial operations, equipment failure carries a severe cost. Consequently, every component choice must prioritize absolute reliability. This is especially true for the human-machine interface. Therefore, selecting a control switch becomes a critical engineering decision. It directly impacts safety, productivity, and total cost of ownership. This blog provides a detailed analysis of a premier solution: the Self-Locking Waterproof Metal Push Button Switch. Specifically, we examine the 16mm model with stainless steel housing and gold-plated pins. Furthermore, we will explore its technical advantages and industry applications. Ultimately, this knowledge empowers you to specify components that enhance product longevity and build client trust.

Part 1: Technical Superiority – A Foundation of Reliability

Firstly, the self-locking mechanism defines this switch’s core purpose. It maintains a positive on or off state until deliberately toggled. Consequently, it prevents accidental deactivation from vibration or impact. This ensures stable control for critical machine functions. For example, it is perfect for master power switches on industrial equipment.

Secondly, the waterproof seal and stainless steel housing provide unmatched environmental defense. Together, they create a robust barrier. Stainless steel resists corrosion and physical damage. Meanwhile, the precision seal blocks moisture, dust, and chemical ingress. As a result, the switch excels in harsh conditions like outdoor or wash-down environments.

Part 2: Electrical and Design Excellence

Moreover, the gold-plated pins ensure superior electrical performance. Gold plating offers excellent conductivity and minimizes contact oxidation. Therefore, it guarantees a stable, low-resistance connection for the product’s entire lifecycle. This reliability is vital for sensitive control circuits and data integrity.

Additionally, the compact 16mm design delivers practical installation benefits. Its low-profile form factor saves valuable panel space. Thus, engineers can create sleeker product interfaces. It also allows integration into devices with strict depth limitations. Every feature collaborates to provide a supremely dependable control interface.

Part 3: Application Focus – Medical and Laboratory Equipment

In medical and laboratory settings, component failure is unacceptable. Here, the self-locking waterproof switch provides essential reliability. For instance, it serves perfectly as a control for sterilization autoclaves. The stainless steel surface allows easy cleaning with harsh disinfectants. Furthermore, the waterproof seal withstands routine sanitization procedures.

Additionally, the switch functions well in diagnostic and analytical instruments. It can be the mode selector for blood analyzers or PCR machines. The self-locking feature ensures the instrument stays in the correct setting during sensitive tests. This prevents costly errors and protects valuable samples. Consequently, it supports compliance with strict industry standards.

Part 4: Application Focus – Outdoor and Heavy-Duty Machinery

For outdoor and marine applications, environmental resistance is paramount. This switch reliably controls lighting on construction vehicles. It also manages winch systems on boats and agricultural equipment. Its construction withstands constant UV exposure, salt spray, and temperature extremes. Therefore, it maintains performance where standard switches would fail.

Moreover, the switch is ideal for agricultural and forestry machinery. It can operate sprayer controls or hydraulic system interfaces. The robust housing protects against dust, mud, and chemical fertilizers. The waterproof rating ensures functionality during rain or equipment washing. As a result, it reduces downtime and maintenance costs in remote operations.

Part 5: Application Focus – Industrial Automation

In factory automation, components face extreme mechanical stress. This switch excels as a start/stop control for CNC machines. It also serves as a safety enable button on robotic cells. The positive tactile feedback gives operators clear confirmation of engagement. Furthermore, the metal construction survives millions of actuations.

Additionally, the switch integrates seamlessly into control panels and operator stations. It provides reliable mode selection for conveyor systems and packaging machines. Its waterproof nature protects against coolants, oils, and airborne particulates. Thus, it ensures continuous operation on busy production floors. This directly supports manufacturing efficiency and output goals.

Part 6: Application Focus – High-End Consumer and Commercial Products

For premium appliance manufacturers, user experience defines brand value. Integrating this switch elevates products like commercial espresso machines. It provides a satisfying tactile response that communicates quality. Moreover, the durable aesthetic enhances the product’s overall perception. Consequently, it justifies a higher market position.

Similarly, the switch enhances professional audio/video equipment and telecommunications gear. It serves as a durable power switch for mixing consoles or network routers. The reliable performance matches the professional demands of these environments. Therefore, it becomes a subtle but important brand differentiator in competitive markets.

Part 7: Procurement Strategy – Total Cost of Ownership Analysis

Component selection requires strategic financial perspective. You must evaluate beyond the initial unit price. Instead, focus on the Total Cost of Ownership (TCO). A cheaper standard switch may save immediate costs. However, it often carries higher risk of premature failure. This leads to warranty claims and expensive unplanned downtime.

Conversely, the self-locking waterproof switch represents a proactive investment. Its superior materials extend the mean time between failures significantly. This directly reduces maintenance labor and replacement part costs. Furthermore, it prevents production losses from unexpected stoppages. Therefore, the higher initial cost spreads across years of reliable service.

Part 8: Procurement Strategy – Value Beyond Price

The switch delivers additional value beyond pure reliability. It enhances your product’s safety profile and user confidence. Also, it contributes to a stronger brand reputation for quality. These factors support premium pricing and customer loyalty. Moreover, it simplifies compliance with international safety and environmental standards.

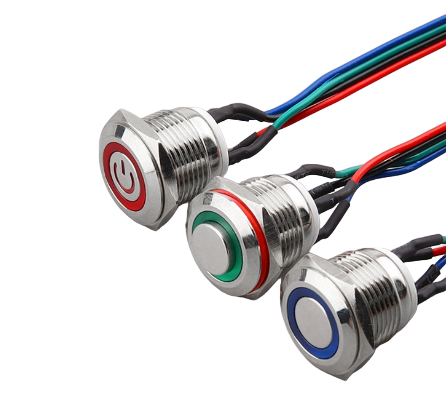

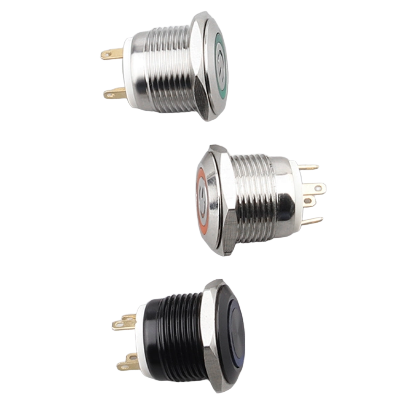

Additionally, the switch offers design flexibility through multiple configurations. It comes in different actuation forces and LED color options. This allows customization for specific application needs. Consequently, you can tailor the user interface without compromising durability. This flexibility adds significant value to your design process.

Part 9: Implementation and Integration

Successful integration requires proper technical planning. First, verify panel cutout dimensions match the 16mm specification. Second, ensure adequate depth clearance behind the panel. Third, follow recommended torque settings during installation. These steps guarantee optimal performance and sealing integrity.

Furthermore, proper electrical connection is crucial. Use appropriate wire gauges for the current rating. Implement strain relief for cable management. Also, consider environmental factors like temperature range. Proper planning ensures the switch performs as engineered throughout its service life.

Part 10: Partner Selection and Collaboration

Choosing the right supplier is equally important. You need a partner with technical expertise and application knowledge. Look for suppliers who provide comprehensive documentation. Also, prioritize those offering engineering support and customization options. A good partner becomes an extension of your design team.

Moreover, evaluate the supplier’s quality control processes and certifications. Ensure they comply with relevant industry standards. Check their manufacturing capabilities and lead time reliability. These factors contribute to a smooth supply chain and consistent product quality.

Part 11: Future Trends and Developments

Industrial interface technology continues evolving. Current trends include smarter switches with integrated sensors. These can monitor usage patterns and predict maintenance needs. Additionally, connectivity options are expanding for IoT integration. The robust physical switch remains relevant in this digital transformation.

Furthermore, material science advances offer new possibilities. Enhanced coatings provide even better corrosion resistance. New sealing materials extend temperature range capabilities. Staying informed about these developments helps future-proof your product designs. It ensures continued competitiveness in changing markets.

Part 12: Conclusion and Next Steps

Specifying the optimal components requires comprehensive analysis. The self-locking waterproof metal switch offers proven reliability across industries. Its technical features directly address common operational challenges. Moreover, it provides excellent long-term value through reduced TCO.

We invite you to explore this solution further for your specific needs. Our technical team can provide detailed application guidance. We offer samples for testing and evaluation. Additionally, we support customization for unique requirements.

Contact us today to discuss your project specifications. Request detailed technical data sheets and 3D models. Learn how our switches can enhance your product’s reliability and value. Let’s collaborate to build more resilient and successful products together. Visit our website for complete product information and support resources.