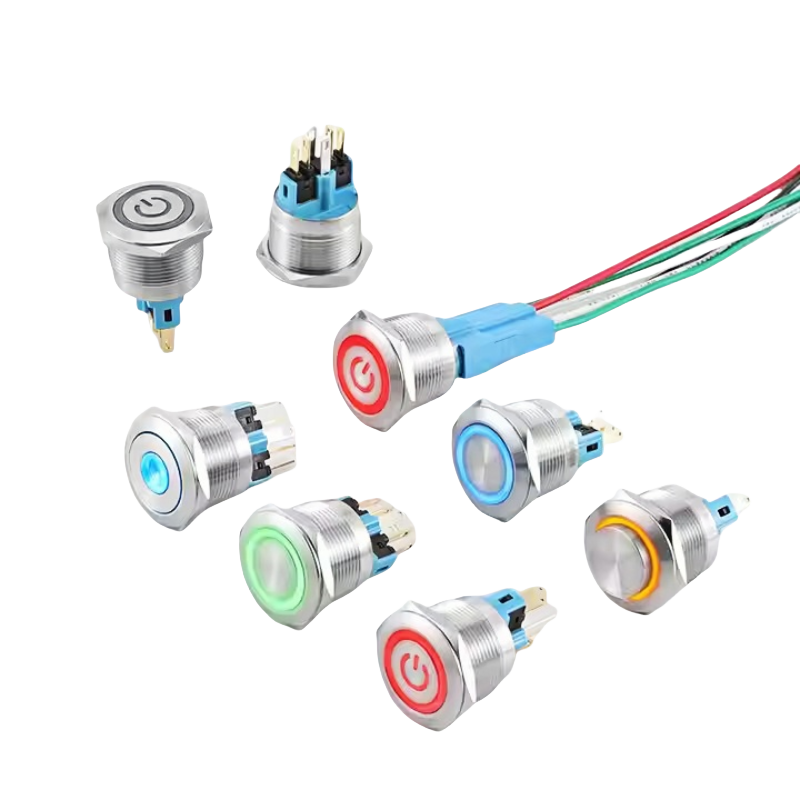

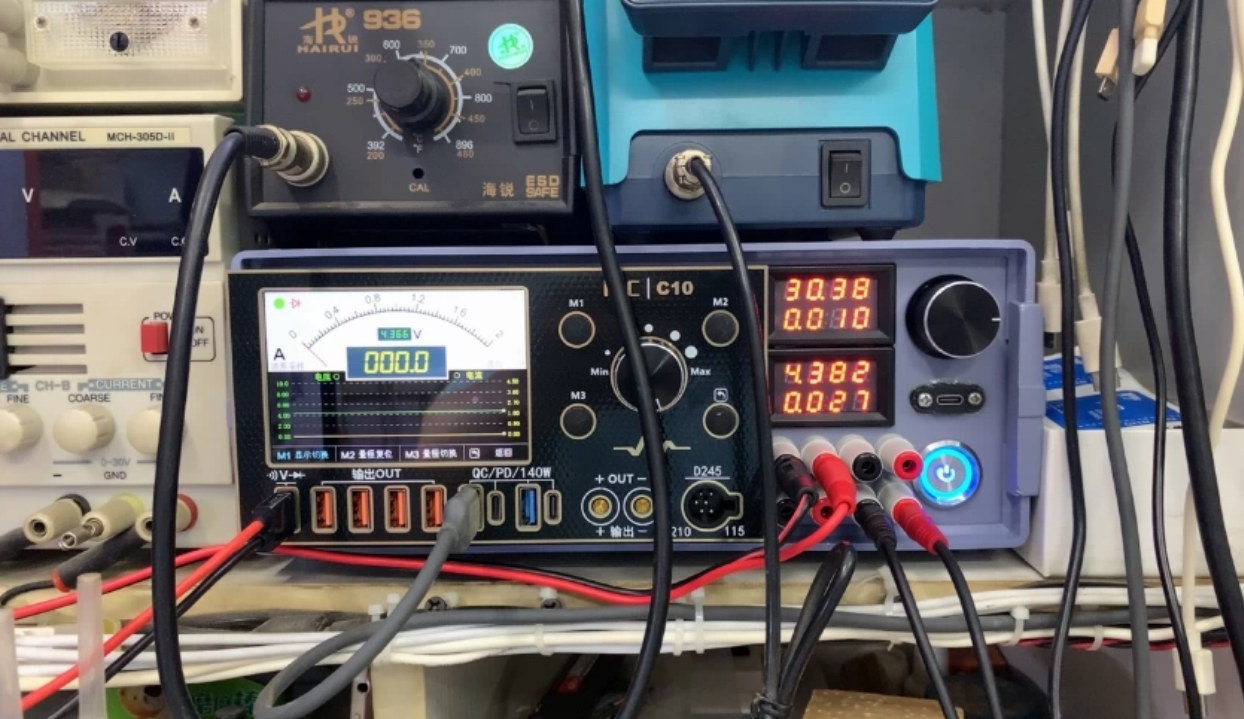

In electronic test labs, repair workshops, and bench setups (like the multi-device workstation in the image), metal illuminated push buttons are far more than just “switches”—they’re the durable, visible control hubs that keep technicians efficient, equipment protected, and workflows uninterrupted. Let’s explore why these robust components are a must-have for B2B electronic workbench setups.

Why Metal Illuminated Push Buttons Fit Electronic Workstations Perfectly

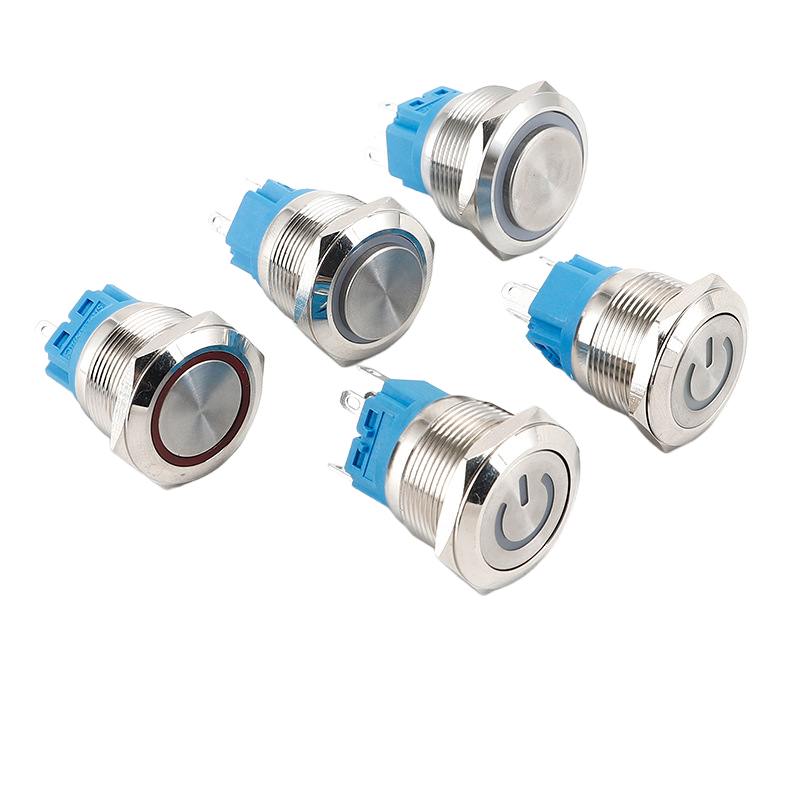

Electronic test/repair environments demand components that balance tactile precision, durability, and visibility—and metal illuminated push buttons check all three boxes:

- Tactile feedback: The firm, defined 2.5-4N pressing force (per typical specs) lets technicians confirm a switch actuation without looking (critical when focusing on sensitive test equipment).

- Durability: Stainless steel/aluminum alloy housings resist scratches, chemical spills, and the wear of frequent daily use (far more robust than plastic switches for high-traffic workbenches).

- LED visibility: Bright, color-coded LEDs (e.g., blue for “power on,” red for “alert”) cut through cluttered bench setups, letting technicians instantly identify device status (even in dimly lit labs).

Key Applications on Electronic Test & Repair Workstations

For setups like the one in the image (featuring power supplies, soldering stations, and multi-meters), metal illuminated push buttons serve 3 core roles:

1. Equipment Power Control

- Soldering stations (e.g., the “936” model in the image): A red-lit metal push button acts as a clear “power on/off” switch—its high-visibility LED ensures technicians don’t leave the station active (reducing fire risks in busy workshops).

- Bench power supplies: Green/blue illuminated buttons trigger output power, with the LED staying lit to confirm the supply is active (preventing accidental voltage surges to sensitive DUTs).

2. Safety Interlocks & Emergency Stops

- High-voltage test setups: A large, red-lit metal push button (rated for IP65 dust/water resistance) serves as an emergency stop—its sturdy metal housing withstands urgent, forceful presses to cut power instantly if a test goes wrong.

- ESD-protected workbenches: Illuminated buttons paired with ESD sensors use LEDs to signal if the workstation is “ESD-safe (green)” or “unprotected (red)”—critical for handling electrostatic-sensitive components (e.g., microchips).

3. Mode/Function Selection

- Multi-function test tools: Dual-color illuminated metal buttons (e.g., amber for “measurement mode,” white for “calibration mode”) let technicians toggle between functions while keeping their eyes on test results—reducing workflow delays.

What B2B Buyers Should Prioritize for Workbench Push Buttons

When sourcing metal illuminated push buttons for electronic workstations, focus on these specs:

- Material: 304 stainless steel (resists corrosion from cleaning solvents) or aluminum alloy (lightweight yet durable).

- LED specs: Low-power (2mA-20mA) LEDs to avoid draining bench power supplies, with dimmable options for lab environments.

- Electrical ratings: Compatibility with 12V/24V (common in bench equipment) and 10A+ current capacity (for high-power tools like soldering stations).

For electronic test and repair businesses, every component on the workbench impacts productivity and safety. Metal illuminated push buttons deliver the reliability, visibility, and durability that plastic alternatives simply can’t match—turning cluttered workstations into streamlined, controlled hubs.

Would you like me to draft a product comparison sheet for metal vs. plastic push buttons for electronic workbenches?