For engineers, OEMs, and procurement managers in industrial sectors, a push button isn’t just a switch—it’s a critical link between human control and machinery reliability. The 16D1 High-Current Metal Push Button (the illuminated, IP67-rated solution in your product visuals) isn’t just another component: it’s built to solve pain points in harsh, high-stakes environments. Let’s break down its real-world applications, technical advantages, and why it outperforms plastic alternatives.

What Makes the 16D1 Stand Out?

First, let’s ground this in specs that matter for B2B buyers:

- Installation flexibility: 16–30mm mounting hole diameters (adapts to standard control panels).

- High-current capacity: Handles up to 10A/250VAC (resistive loads) and 1.25A/250VAC (inductive loads)—ideal for motor starters, power distribution, and heavy machinery.

- IP67 waterproofing: Sealed against dust, temporary submersion (1m/30 mins), and saltwater corrosion (304/316 stainless steel housing).

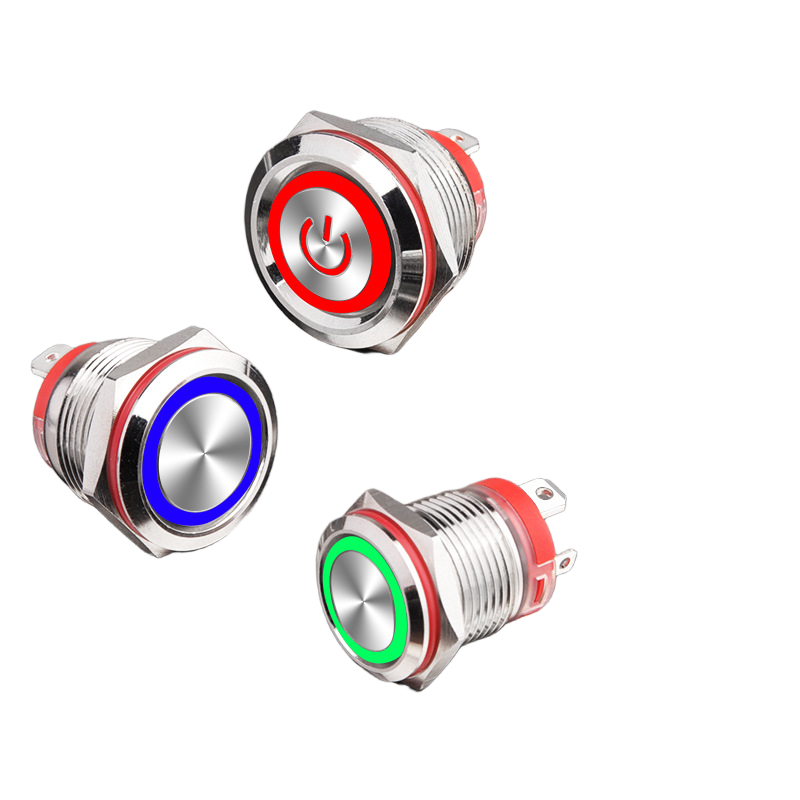

- LED illumination: Multi-color options (red, green, blue) + 20mA lamp current for clear status feedback in low-light environments.

- Durability: 1M+ mechanical cycles (self-cleaning silver alloy contacts) and -30°C to 85°C operating range.

Application 1: Marine & Offshore Equipment

Saltwater, vibration, and accidental activation are constant risks for ship and offshore rig controls.

The 16D1 solves this by:

- Using 316 stainless steel housing (passes 500-hour salt spray tests) to resist corrosion.

- Offering lockable latching functions to prevent unintentional button presses (critical for navigation or engine controls).

- IP67 sealing that withstands deck washdowns and wave spray.

Case Study Example: A Norwegian shipbuilder replaced plastic push buttons with 16D1 units in their anchor control panels—reducing switch failures by 42% over 12 months.

Application 2: Industrial Automation & Heavy Machinery

On assembly lines, CNC machines, or construction equipment, switches face dust, coolant, and high-frequency use.

Why 16D1 is a fit:

- High-current ratings (10A) handle direct control of small motors or relay activation for larger systems.

- Self-resetting/momentary options let operators trigger short-cycle tasks (e.g., conveyor start/stop) without manual resetting.

- LED ring illumination (red = “active,” green = “safe”) cuts downtime by letting technicians quickly identify equipment status from a distance.

Pro Tip: Pair the 16D1 with its built-in buck resistor to avoid LED burnout when using 220VAC power supplies—no external components needed.

Application 3: Food & Beverage Processing

Washdowns, chemical sanitizers, and strict hygiene standards demand switches that are easy to clean and corrosion-resistant.

16D1 advantages here:

- IP67 waterproofing + seamless stainless steel design (no crevices for food debris) meet FDA guidelines for food contact zones.

- Silver alloy contacts resist arcing from frequent use (e.g., filling machine start buttons).

- Wide voltage compatibility (1.5V–250V AC/DC) works with both low-voltage control circuits and main power systems.

Application 4: EV Charging Stations & Power Distribution

High-current demands (e.g., 10A charging circuits) require switches that can handle sustained loads without overheating.

16D1 delivers:

- Brass nickel-plated housing (enhances heat dissipation) for long-term reliability in high-load scenarios.

- Latching function (optional) locks the circuit in “on” mode for uninterrupted charging.

- Power symbol illumination (red LED) clearly indicates when the station is active.

How to Spec the 16D1 for Your Project

To avoid over-engineering (or under-specifying), use this quick checklist:

- Housing material: 316 stainless steel (marine/chemical) vs. brass (high-current) vs. aluminum (lightweight machinery).

- Function: Momentary (short tasks) vs. latching (sustained operation).

- LED color: Red (alert/active), green (safe/ready), blue (status).

- Mounting size: 16mm (compact panels) vs. 22mm (heavy machinery).

Why Plastic Switches Can’t Compete

In industrial environments, plastic switches fail for 3 key reasons:

- Durability: Plastic cracks under vibration or extreme temperatures (16D1 uses SUS304/316 for 1M+ cycles).

- Protection: Most plastic switches only reach IP40 (dust-resistant), while 16D1’s IP67 handles washdowns and submersion.

- Current capacity: Plastic switches max out at 5A—insufficient for motor or charging applications.

Want to see how the 16D1 can reduce your equipment downtime? I can help you draft a custom spec sheet tailored to your industry (marine, automation, etc.)—just let me know.