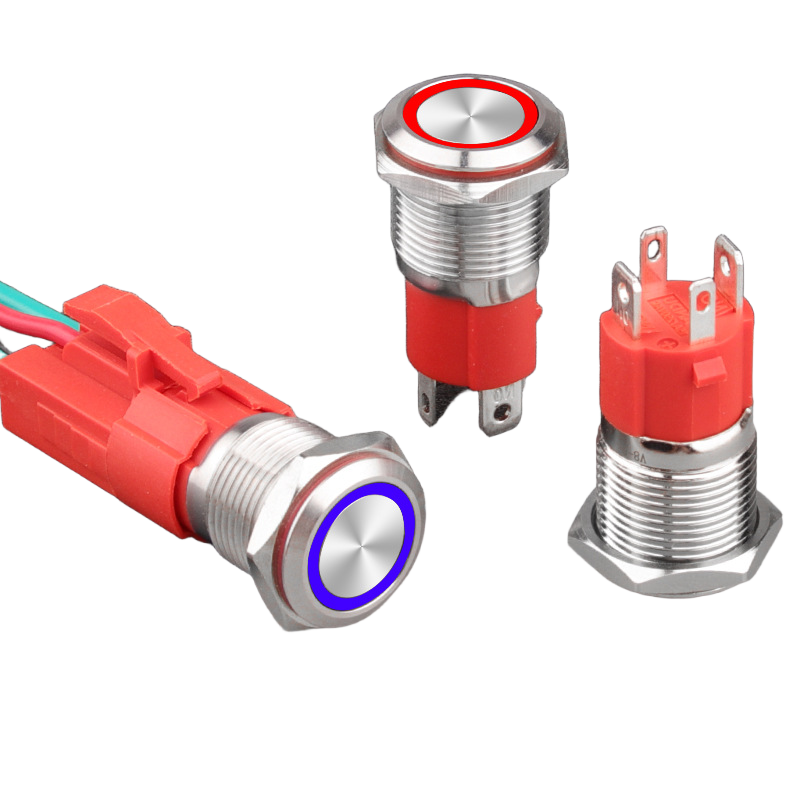

In modern smart factories and automated production lines, control panel reliability directly impacts productivity and equipment safety. Standard plastic push buttons often fail under the demanding conditions of high-load, high-frequency industrial operations. Our D-Series 15A High Current 16mm Metal LED Push Button Switch provides the robust, reliable control solution that industrial automation systems require.

In modern smart factories and automated production lines, control panel reliability directly impacts productivity and equipment safety. Standard plastic push buttons often fail under the demanding conditions of high-load, high-frequency industrial operations. Our D-Series 15A High Current 16mm Metal LED Push Button Switch provides the robust, reliable control solution that industrial automation systems require.

Unique Challenges in Industrial Automation Environments

Typical industrial settings present specific challenges:

24/7 continuous operation requiring hundreds of thousands of actuations

High electromagnetic interference demanding stable signal transmission

Exposure to oil, dust, moisture, and other contaminants

Gloved operator use necessitating clear tactile feedback

Rapid fault diagnosis requiring unambiguous visual indication

Targeted Technical Solutions

1. High Load Capacity for Diverse Equipment Needs

With 15A rating at 110V/250V AC-15, our switch handles:

Motor start/stop control (including high inrush currents of induction motors)

Heating element control (injection molding machines, drying equipment)

Transformer and solenoid valve control

Branch circuit control in three-phase systems

Real Application Case: Packaging Line Control Station

In a food packaging automation line where each machine completes 6,000 cycles per hour, control buttons are actuated over 20,000 times daily. Our metal push button switches have operated continuously for 18+ months without failure, significantly outperforming previous plastic switches (average lifespan: 6 months).

2. Optimized Mechanical Design & User Experience

3mm button travel + 1.5mm contact stroke: Provides definitive actuation feedback, even through thick industrial gloves

2.5-4N actuation force: Prevents accidental presses while minimizing operator fatigue

Self-locking/self-resetting options: Adapts to different control logic requirements

Self-locking: Ideal for mode selection, power switches

Self-resetting: Perfect for start, stop, reset functions

3. Environmental Resilience & Safety Features

IP65/IP67 protection: Fully dust-proof and resistant to high-pressure washdowns, suitable for food, pharmaceutical, and cleanroom applications

Wide temperature range (-30°C to 85°C): Operates reliably in cold storage, foundries, and other extreme environments

2500VAC dielectric strength: Ensures operator safety with excellent electrical isolation

Low contact resistance (≤50mΩ): Reduces energy loss and heat generation, improving efficiency

Application Configurations for Specific Automation Equipment

A. CNC Machine Control Panel

ecommended Configuration: • Red LED self-resetting button: Emergency stop • Green LED self-resetting button: Cycle start • Yellow LED self-locking button: Mode selection • Blue LED button: Coolant control • IP67 rating + stainless steel housing Key Advantages:

Metal housing resists cutting fluid corrosion

Bright LEDs remain visible in oily environments

High mechanical endurance for frequent operation

B. Industrial Robot Teach Pendant

Recommended Configuration: • White LED self-resetting button: Coordinate recording • Green LED self-locking button: Program start/pause • 16mm compact size for handheld devices • Anodized aluminum alloy housing for reduced weight

C. Conveyor System Control Station

In multi-line junction control stations, our switches offer:

Modular installation: Multiple hole diameters (16-30mm) accommodate various panel designs

Stackable layout: Saves control panel space

Standardized electrical interface: Simplifies wiring and reduces maintenance costs

Performance Comparison vs. Competitors

| Feature | Our D-Series Metal Switch | Standard Plastic Industrial Switch | Advantage Analysis |

|---|---|---|---|

| Electrical Life | >30,000 cycles (15A/250V) | Typically 10,000-15,000 cycles | 100%+ longer lifespan |

| Environmental Tolerance | IP65/IP67, -30~85°C | IP54, -10~70°C | Suitable for harsher conditions |

| Contact Material | Silver tin oxide alloy | Standard silver alloy | Superior arc resistance |

| Housing Material | SUS304/Ni-plated brass/Anodized Al | Engineering plastic | Higher mechanical strength, corrosion resistant |

Installation & Maintenance Recommendations

Panel Design Optimization:

Maintain ≥20mm spacing between adjacent buttons for gloved operation

Angle control panels 15-30° for optimal LED visibility

Use sealing gaskets to ensure IP rating integrity

Wiring Considerations:

Recommend crimp terminals for reliable connections

Add appropriate series resistors to LED circuits (maintain 2-20mA range)

Consider parallel arc suppression circuits for inductive loads

Preventive Maintenance Schedule:

Check contact resistance every 6 months

Perform dielectric strength tests annually

Regularly clean button surfaces to maintain LED light transmission

Industry-Specific SEO Keywords

Optimized for industrial automation buyers and engineers:

“CNC control panel push button 15A metal”

“Industrial automation high current button IP67”

“SUS304 emergency stop button 16mm”

“Packaging machine control switch 300k cycles”

“Robot teach pendant button latching LED”

“Conveyor control station waterproof button”

“Food machinery stainless steel button easy clean”

“PLC control cabinet compatible push button”

Innovative Application Extensions

With Industry 4.0 advancement, our switches enable new smart factory applications:

Condition monitoring integration: Predict maintenance schedules via actuation counting

Programmable multi-color LEDs: Visual status indication (green-running, yellow-standby, red-fault)

Custom tactile feedback: Adjust travel and force for different processes

ROI Analysis

Example: 10-station assembly line:

Standard plastic switch: Unit price ¥8, 30% annual replacement rate, annual maintenance ~¥240

Our metal switch: Unit price ¥25, 3-year lifecycle, annualized cost ~¥8.3

Additional benefits: Reduced downtime, improved operational reliability, lower safety risks

Conclusion

In industrial automation, every control component is a building block of production line reliability. Our D-Series high current metal push button switches are more than just switches—they are:

Guarantors of production efficiency

Guardians of operational safety

Intelligent long-term investments

Whether designing new automation equipment or upgrading existing production lines, choosing the right control components is critical. Reliability isn’t an expense—it’s an investment in future productivity.

Recommended Next Steps:

Request free samples for on-site testing

Download detailed 3D models for panel design

Schedule a consultation with our application engineers

Obtain industry-specific configuration proposals

For deeper technical matching to your specific application, please share your equipment parameters and working environment details. We’ll provide customized solutions tailored to your needs.