In the high-stakes world of industrial automation, system failure is not an option. Downtime costs thousands per minute, and operator safety is paramount. A critical line of defense in this environment is the humble yet vital emergency stop button. Not all e-stop buttons are created equal. The Rugswt Series M Metal Emergency Stop Switch, designed for 16mm, 19mm, and 22mm panel cutouts, is engineered from the ground up to solve the most pressing safety and reliability challenges in power automation.

In the high-stakes world of industrial automation, system failure is not an option. Downtime costs thousands per minute, and operator safety is paramount. A critical line of defense in this environment is the humble yet vital emergency stop button. Not all e-stop buttons are created equal. The Rugswt Series M Metal Emergency Stop Switch, designed for 16mm, 19mm, and 22mm panel cutouts, is engineered from the ground up to solve the most pressing safety and reliability challenges in power automation.

This blog post will detail how its specific technical parameters translate into concrete solutions for your toughest industrial applications.

Core Problem Solved: Unreliable Shutdown in Critical Moments

A standard push-button might fail under extreme conditions—corrosion from washdowns, contact welding due to high inrush currents, or mechanical jamming in cold environments. The Series M is built to eliminate these risks.

1. Problem: Corrosion & Degradation in Harsh Environments

Application: Food & Beverage Processing, Pharmaceutical Plants, Outdoor Marine Equipment.

How Our Switch Solves It:

IP55 Sealing & 304 Stainless Steel/Brass Housing: The switch achieves a front-panel rating of IP55, deflecting dust and low-pressure water jets. The choice of SUS304 stainless steel or nickel-plated brass for the housing provides exceptional resistance to corrosive chemicals, steam cleaning, and salty air, ensuring the external mechanism never seizes.

Wide Temperature Tolerance (-30°C to 85°C): Whether in a freezer warehouse or near an oven, the switch’s modified nylon PA66 base and internal materials remain stable, preventing brittleness or deformation.

2. Problem: Electrical Failure & Contact Welding Under Load

Application: Motor Control Centers (MCCs), CNC Machinery, Heavy-duty Conveyor Systems.

How Our Switch Solves It:

High-Capacity, Alloy Contacts: Featuring silver tin oxide alloy contacts, the switch handles a wide range of voltages (1.5V-250V AC/DC) and robust currents (3A resistive at 250V AC). This specialized alloy is highly resistant to welding and arcing, a common cause of failure in inductive loads like motors.

Proven Reliability Metrics: With an electrical life of >500,000 cycles and a mechanical life exceeding 1 million cycles under standard loads, it is built for decades of dependable service in high-cycle panels.

3. Problem: Unintentional Activation or Failure to Activate

Application: Robotics Cells, Assembly Lines with High Human Traffic.

How Our Switch Solves It:

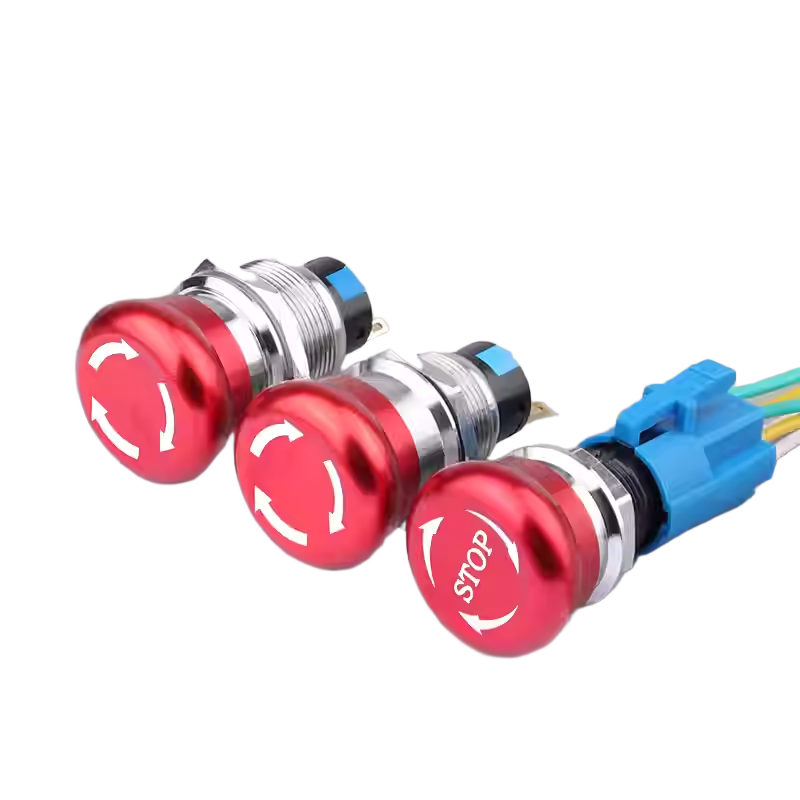

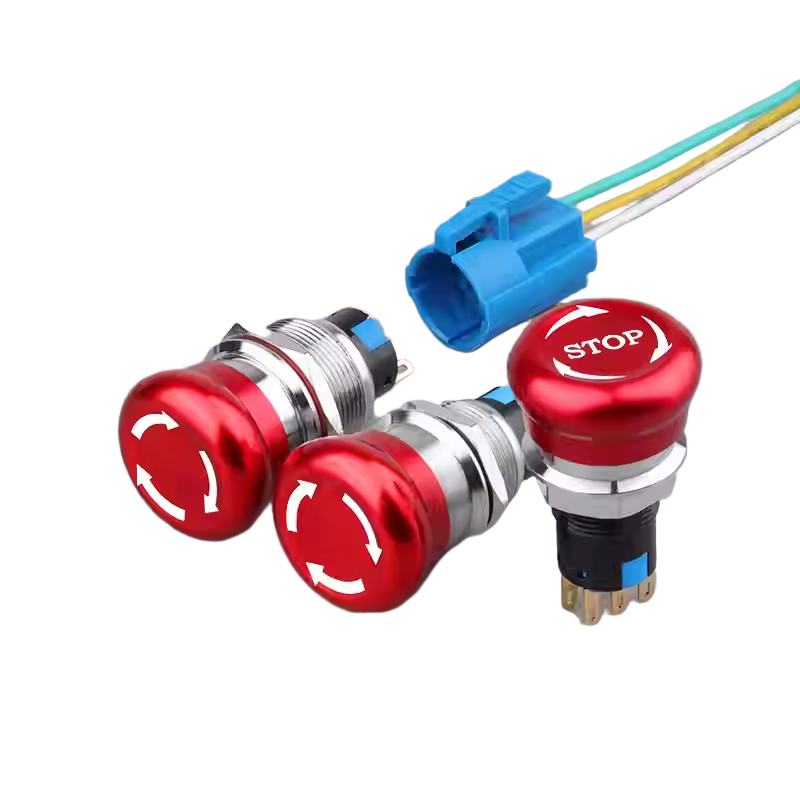

Distinct, Ergonomic M-Shaped Actuator: The large, red, concave button is instantly recognizable by sight and touch, even for a gloved hand. This M-shaped design with a large end face allows for quick, positive engagement from any angle, reducing reaction time in a panic situation.

Clear Tactile Feedback & Rotation Lock: A defined 3mm keystroke with 1.5mm contact travel provides unambiguous physical confirmation of activation. The left/right rotation lock mechanism ensures the button stays depressed until manually reset, preventing automatic restart and signaling the fault location.

Technical Deep Dive: Parameters That Matter for System Designers

When integrating a safety component, engineers need precise data. Here’s what our specifications mean for your design:

Versatile Mounting (16/19/22mm): Offers compatibility with a vast range of existing panel designs and global standards.

Contact Configuration Flexibility (1NO1NC / 2NO2NC): Provides wiring flexibility for diverse safety circuit logic, including dual-channel safety monitoring for Performance Level *d* or *e* (when used in a qualified safety circuit).

Gold-Plated Pins & Low Contact Resistance (<50mΩ): The 2.8 x 0.5mm gold-plated pins ensure a gas-tight, oxidation-resistant connection in the socket, guaranteeing signal integrity and voltage drop over time. The consistently low contact resistance is critical for low-voltage control signals.

Built-in Buck Resistor for LED: Simplifies panel design by allowing direct connection of a wide-range LED indicator without the need for an external resistor, saving space and assembly time.

Conclusion: More Than a Component, A Safety Partner

The [Your Brand Name] Series M Emergency Stop Button is not just a switch; it’s a engineered safety solution. It directly addresses the real-world problems of corrosion, electrical reliability, and human factors that plague generic components.

By choosing a switch with these precise specifications—IP55 sealing, wide-temperature materials, high-current alloy contacts, and fail-safe mechanical design—you are investing in reduced downtime, enhanced operator safety, and long-term system integrity.

Ready to specify reliability?

Contact our engineering support team today to discuss your specific application.