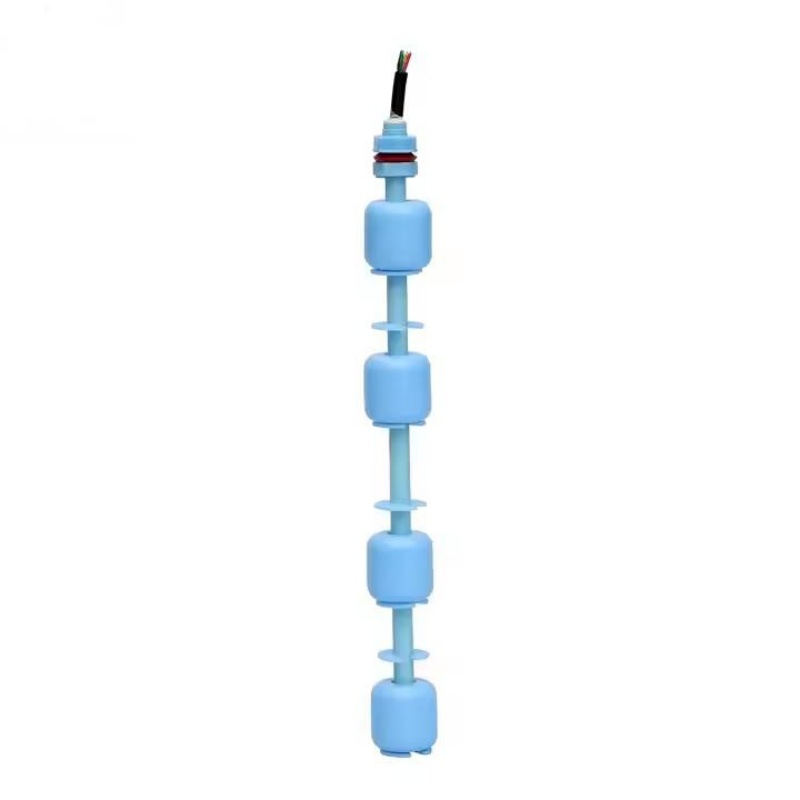

Industrial Water Level Floats are pivotal for maintaining operational integrity in extreme conditions, from chemical processing plants to offshore rigs. For businesses requiring uncompromising reliability, the 220mm Rod Liquid Water Level Float Switch for Swimming Pool, Bilge Pump & Industrial Applications stands as a benchmark in fluid control technology. This guide outlines key criteria for selecting sensors that endure harsh environments while optimizing system performance.

- Material Resilience Against Corrosive Media

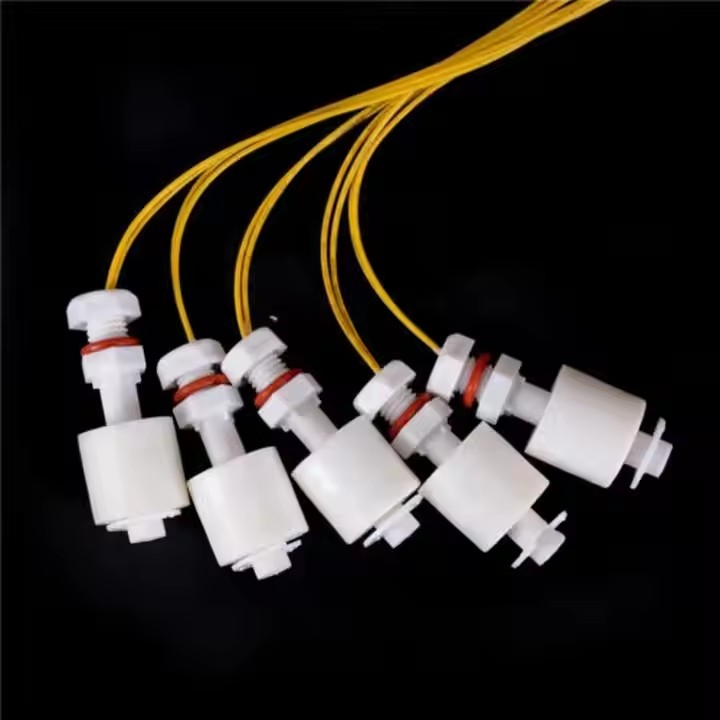

Industrial settings often expose equipment to acids, solvents, and abrasive fluids. The Industrial Water Level Float utilizes corrosion-resistant PP/Plastic/POM composites, engineered to resist chemical degradation and mechanical stress. With an IP67 waterproof rating, it thrives in submerged or high-humidity applications like wastewater treatment and marine bilge systems, ensuring longevity where standard switches fail.

- Wide Operational Temperature Tolerance

Extreme heat or cold disrupts sensor accuracy. This float switch operates flawlessly from -40°C to 120°C, making it ideal for foundries, refrigeration units, or desert-based solar farms. Its hermetically sealed design prevents condensation-related malfunctions, a critical feature for food processing and pharmaceutical industries.

- Customizable Configuration for Complex Setups

Rigid sensor designs complicate installation in tight spaces. The 220mm sensor body and adjustable wire length (default 350mm) allow flexible mounting in tanks, pipes, or machinery. N.O/N.C contact options enable compatibility with PLCs, alarms, and pump controllers, streamlining integration into automated industrial networks.

- High-Load Electrical Capacity

Industrial circuits demand robust power handling. With a 1.5A/200VDC rating and 10W/50W load capacity, this Industrial Water Level Float manages heavy-duty pumps and motors without relay intermediaries. Its switching transducer output ensures precise signal transmission, reducing false triggers in vibration-prone environments like mining equipment or HVAC systems.

- Compliance with Industry-Specific Standards

Regulatory adherence minimizes liability risks. The float switch’s 100VDC/220VDC dual voltage certification aligns with ATEX, IECEx, and marine safety protocols. Its 220mm rod length provides accurate level detection in large-scale tanks, while the non-reactive materials meet FDA and USDA guidelines for sensitive applications.

Engineered for Reliability, Built for Industry

Selecting an Industrial Water Level Float requires balancing durability, precision, and adaptability. The 220mm Rod Liquid Water Level Float Switch exceeds these demands, offering military-grade performance in oil refineries, automotive cooling systems, and agricultural irrigation.

For operations where sensor failure is not an option, our Industrial Water Level Float delivers proven results. Visit our website to request a site-specific compatibility assessment or explore technical documentation. Partner with a solution designed to withstand the toughest industrial challenges—contact our engineering team today to elevate your fluid management strategy.