The 1M Flange-Mounted Diesel Sensor is a critical component for accurate fuel monitoring in heavy-truck diesel or oil tanks. Designed for industrial durability, this sensor combines stainless steel construction (SUS304/316L), IP67 protection, and SAE/BSP mounting compatibility to ensure reliable performance in harsh environments. Below is a step-by-step guide to installing this sensor effectively.

Preparation for Installation

Verify the tank specifications match the 1M Flange-Mounted Diesel Sensor’s parameters: 100-2000mm customizable length, SAE 5-hole flange, or BSP 1 1/14″ thread. Ensure the tank is depressurized and free of residual fuel to avoid contamination. Gather tools such as a wrench, thread sealant, and multimeter for calibration.

Mounting the Sensor

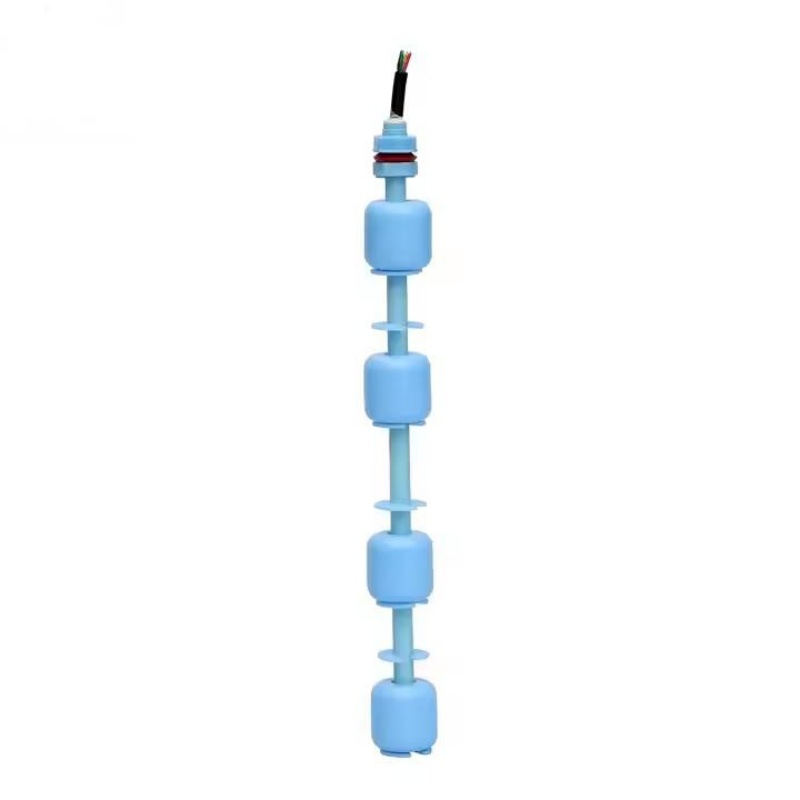

Align the sensor’s flange or threaded base with the tank’s pre-drilled mounting port. Apply thread sealant to prevent leaks, then secure the 1M Flange-Mounted Diesel Sensor using bolts or a wrench. Confirm the float inside the tank moves freely without obstruction. For tanks with irregular shapes, adjust the sensor’s length (up to 2000mm) to maintain optimal contact with the fuel surface.

Wiring and Calibration

Connect the sensor’s 4-20mA or 0-5VDC output wires to the vehicle’s monitoring system. Use a multimeter to test signal continuity and adjust the output range based on the tank’s capacity. Calibrate the sensor by comparing readings against manual measurements, ensuring accuracy within ±10-40mm. For advanced integration, configure CAN bus or J1939 protocols if supported.

Post-Installation Testing

Refill the tank gradually while monitoring real-time data from the 1M Flange-Mounted Diesel Sensor. Check for leaks around the flange or threads and verify IP67-rated seals withstand pressure fluctuations. Conduct a long-term test to validate stability, especially under vibration or extreme temperatures common in heavy-truck operations.

Why Choose the 1M Flange-Mounted Diesel Sensor?

This sensor offers unmatched precision for fleet managers and logistics operators. Its corrosion-resistant SUS304/316L float ensures longevity, while customizable outputs (4-20mA/0-5VDC) and mounting options (SAE/BSP) simplify integration into existing systems. Backed by a 1-year warranty and OEM/ODM/OBM support, it adapts to specialized fuel tank designs.

For detailed technical specifications or bulk orders of the 1M Flange-Mounted Diesel Sensor, visit our website to contact our engineering team. Optimize your heavy-truck fuel monitoring with industrial-grade reliability and tailored solutions.