Maintaining precise water levels in commercial pools and industrial systems is critical for operational efficiency and equipment longevity. The 220mm Rod Float Switch offers a robust solution for automated liquid level control, combining heavy-duty construction with advanced sensor technology. This guide outlines key steps to install and optimize this high-performance device for B2B applications.

Step 1: Pre-Installation Preparation

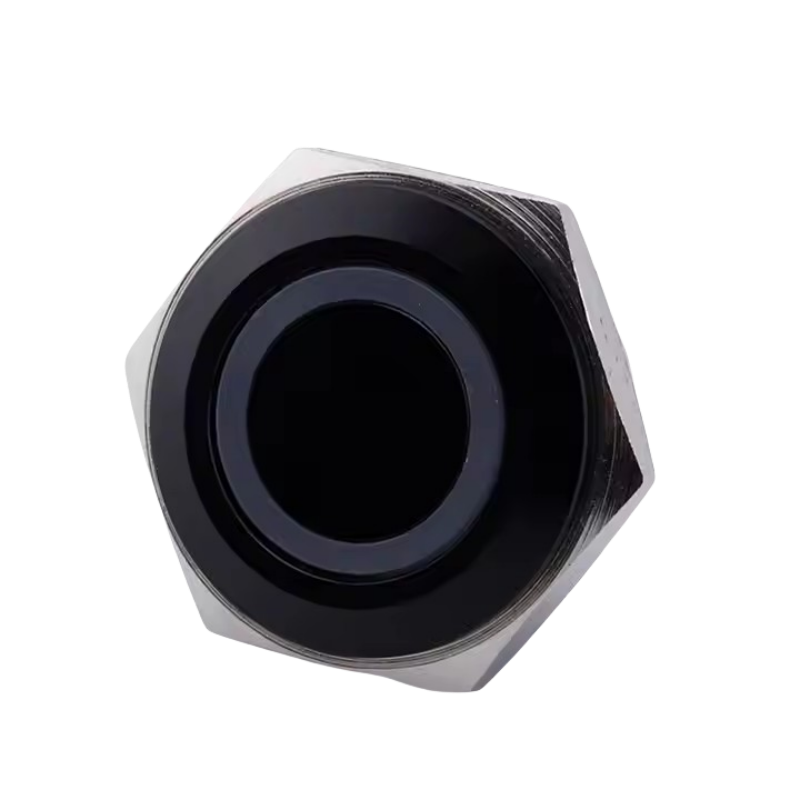

Verify compatibility by confirming your system’s voltage (100–200VDC) and load requirements (up to 1.5A/50W). The 220mm Rod Float Switch’s corrosion-resistant PP/POM housing ensures durability in chlorine-rich pool environments or industrial settings. Ensure the mounting location aligns with the 220mm sensor length and allows vertical submersion.

Step 2: Secure Mounting

Attach the switch to a stable surface using stainless steel brackets (not included) to prevent vibration-related errors. For marine bilge or humidifier systems, position the float away from turbulent zones to avoid false triggering. The IP67 waterproof rating guarantees reliable performance even in submerged conditions.

Step 3: Electrical Integration

Connect the N.O/N.C contacts to your control circuit based on desired logic (e.g., pump activation on high/low level). The default 350mm wire length can be extended for large tanks or industrial equipment. Use waterproof connectors to maintain integrity in wet environments.

Step 4: Calibration Testing

Adjust the float angle to set activation thresholds. Test under load (up to 120°C) to validate switching accuracy. For automotive or HVAC applications, simulate extreme temperatures (-40°C to 120°C) to confirm material resilience.

Step 5: Maintenance Protocol

Inspect the float mechanism quarterly for debris buildup. The POM/PP construction resists scaling, but acidic or abrasive fluids may require more frequent checks. Document performance metrics to align with ISO-compliant maintenance schedules.

Why Choose the 220mm Rod Float Switch?

– Precision Engineering: 220mm sensor body enables exact level detection in pools, bilge pumps, and industrial tanks.

– High-Load Capacity: 1.5A/200VDC rating supports demanding commercial systems.

– Customizable Integration: Optional wire extensions and mounting kits adapt to complex installations.

For B2B clients seeking a reliable water level management partner, our 220mm Rod Float Switch delivers unmatched durability and precision. Contact our engineering team today to discuss bulk pricing or tailored configurations for your automotive, marine, or industrial projects. Visit our Website to request a technical datasheet or schedule a consultation.

Optimize your liquid control systems with the 220mm Rod Float Switch—engineered for accuracy, built for harsh environments, and trusted by global industrial leaders.