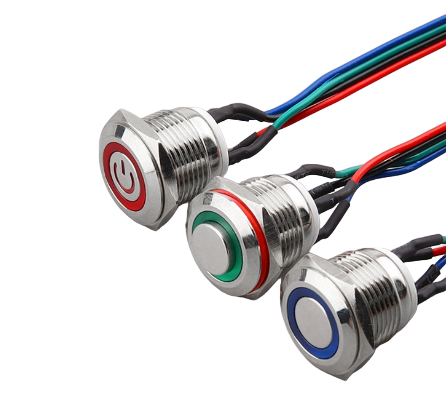

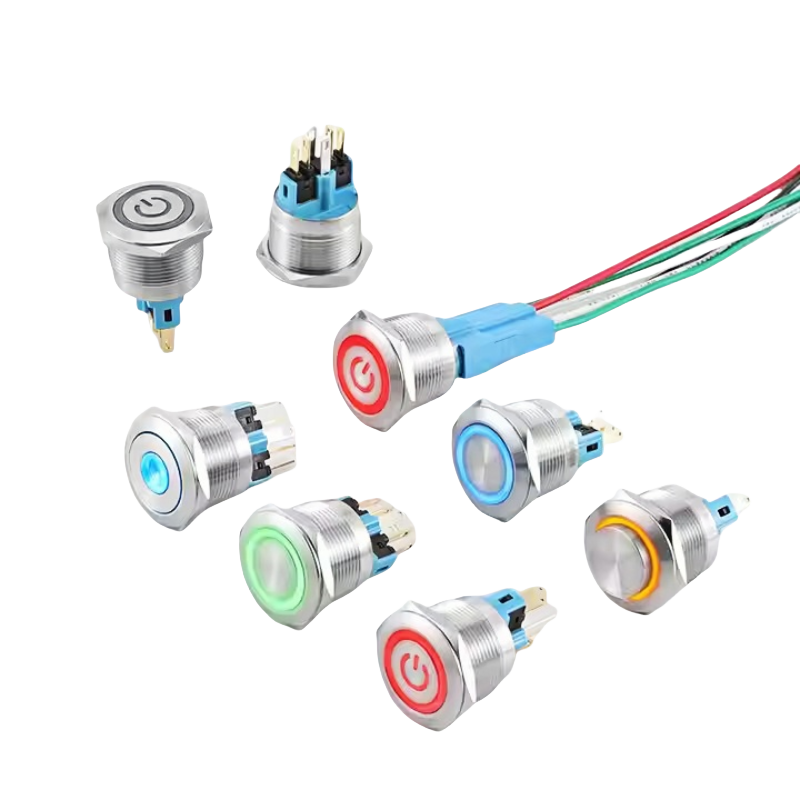

When it comes to industrial control panels, a reliable push button switch isn’t just a component—it’s the “nerve center” of safe, efficient operations. Illuminated push button switches (like the models with LED indicators in the image) combine tactile control with visual status feedback, making them indispensable in high-demand B2B scenarios.

When it comes to industrial control panels, a reliable push button switch isn’t just a component—it’s the “nerve center” of safe, efficient operations. Illuminated push button switches (like the models with LED indicators in the image) combine tactile control with visual status feedback, making them indispensable in high-demand B2B scenarios.Here are the top 5 applications where these switches deliver maximum value:

1. Industrial Automation & Production Lines

On CNC machines, packaging lines, or robotic assembly systems, illuminated push buttons act as the “start/stop command center.” For example:

- Green-lit “Start” buttons trigger production cycles, while red-lit “Emergency Stop” buttons cut power instantly (complying with ISO 13850 safety standards).

- LED indicators eliminate ambiguity in dim factory environments—operators can instantly identify if a machine is active, idle, or in fault mode.

Ideal for: Machinery manufacturers, factory automation integrators.

2. Energy & Power Distribution Systems

In electrical cabinets, generators, or renewable energy (wind/solar) control units, these switches handle high-voltage/current loads:

- They manage circuit on/off operations and serve as emergency shut-off devices for transformers or UPS systems.

- IP65/IP67 waterproof ratings (as per the technical specs) make them suitable for outdoor power stations or damp electrical rooms.

Ideal for: Power equipment suppliers, electrical engineering firms.

3. Transportation & Heavy Machinery

From train control panels to marine vessel systems, illuminated push buttons withstand extreme conditions:

- Their vibration-resistant design (and -30℃~85℃ operating range) adapts to railway or construction machinery (e.g., cranes, excavators).

- LED backlighting ensures visibility in dark cockpit environments or outdoor shipping yards.

Ideal for: Transportation equipment builders, heavy machinery manufacturers.

4. Medical & Laboratory Equipment

In surgical tables, diagnostic devices (CT/MRI), or life-support systems, precision and safety are non-negotiable:

- Low-noise, dustproof switches prevent contamination in sterile environments.

- Dual-color LEDs (e.g., green = “normal,” red = “alert”) help medical staff monitor equipment status at a glance.

Ideal for: Medical device OEMs, lab equipment providers.

5. Specialized Hazardous Environments

For chemical plants, mines, or oil rigs, explosion-proof-rated illuminated switches (optional per specs) ensure safe operation:

- They resist flammable dust/gases while providing clear visual feedback for critical controls (e.g., valve adjustments, pump starts).

Ideal for: Hazardous area equipment integrators, mining solution providers.

Whether you’re designing a control panel for a factory line or a medical device, the right illuminated push button switch balances durability, safety, and usability.