Industrial control panels demand robust solutions because managing high power in compact spaces is a common challenge. Specifically, engineers need components that switch high currents reliably while also enduring tough physical use. Therefore, component selection becomes critical for overall system integrity. The 15A high-current 16mm metal LED push-button switch is designed precisely for this role, as it combines strong electrical capacity with resilient construction. Consequently, this guide will explore its detailed design, illustrate key industry applications, and provide a clear selection framework. Ultimately, this knowledge will help you build systems that are safer, more reliable, and more efficient.

Industrial control panels demand robust solutions because managing high power in compact spaces is a common challenge. Specifically, engineers need components that switch high currents reliably while also enduring tough physical use. Therefore, component selection becomes critical for overall system integrity. The 15A high-current 16mm metal LED push-button switch is designed precisely for this role, as it combines strong electrical capacity with resilient construction. Consequently, this guide will explore its detailed design, illustrate key industry applications, and provide a clear selection framework. Ultimately, this knowledge will help you build systems that are safer, more reliable, and more efficient.

Engineered for Power and Endurance: Core Design Principles

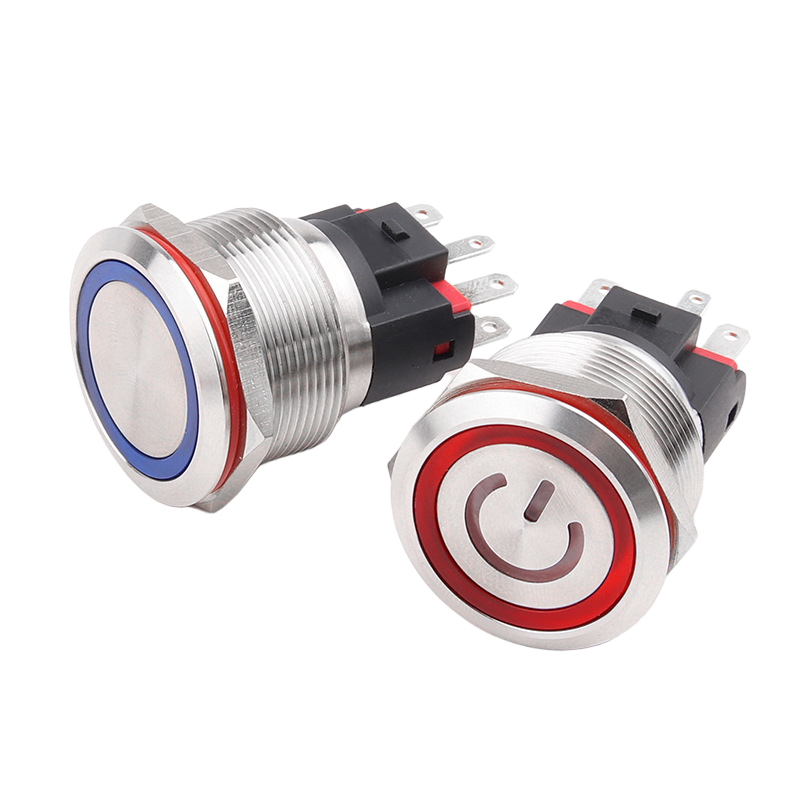

This switch delivers exceptional performance through smart, synergistic design. Firstly, its electrical design ensures safe, high-current operation. The use of gold-plated pins and large silver contacts is fundamental, as they minimize electrical resistance. This reduction is crucial because it directly lowers voltage drop and heat generation under a full 15A load. Consequently, operational safety improves significantly. Furthermore, an impressive 1900VAC dielectric strength offers essential protection by guarding against dangerous voltage spikes common in industrial settings.

Secondly, its mechanical build guarantees long-term durability. Precision CNC machining initially creates a consistent and high-quality housing. Then, an IP67-rated sealing ring completes a robust seal that effectively blocks dust, oils, and water jets. As a result, this design supports an extended mechanical life of 50,000 cycles for momentary use while also handling extreme temperatures from -30°C to +80°C. Additionally, a high-brightness LED provides clear operator feedback, which is easily visible in any lighting condition.

Proven in Demanding Applications: Industry Use Cases

This switch proves vital in sectors where standard components typically fail. In Industrial Automation, for instance, high inrush currents from solenoid valves and motor starters are normal. For example, when used as the main actuator control on an automated stamping press, its robust contacts resist arc erosion from inductive loads. Meanwhile, its IP67 seal reliably keeps out conductive metal dust and coolant mist, thereby preventing costly downtime and maintaining production line efficiency.

Similarly, Renewable Energy and Power Distribution systems require equally durable components for managing loads from solar arrays or battery storage. Here, the switch’s high dielectric strength is particularly beneficial because it safeguards against grid-borne transients. Moreover, its wide operational temperature tolerance ensures stable performance in non-climate-controlled environments, from cold outdoor sites to hot rooftop units. Notably, its CE and RoHS certifications also facilitate compliance with stringent infrastructure project standards.

Likewise, the Transportation and Heavy Equipment sector faces a combination of brutal conditions, including high current, constant vibration, and severe weather exposure. Consider its application in a commercial EV charging station or for auxiliary power control in an agricultural harvester. In these roles, the switch’s corrosion-resistant housing withstands harsh environments, while its secure panel-mount design resists vibration-induced loosening. Simultaneously, the waterproof seal endures weather, road spray, and washdowns. Most importantly, the bright LED offers immediate state recognition, which directly enhances operator safety in these critical mobile systems.

A Practical Guide to Selection and Flawless Installation

Selecting and installing this switch successfully requires a careful, step-by-step methodology. Initially, you must analyze your electrical load thoroughly by confirming the system’s operating voltage and characterizing the 15A load type—whether resistive, inductive, or capacitive. This step is essential because it determines contact stress and ensures optimal component longevity.

Following this, conduct a detailed environmental audit. Specifically, identify potential exposures such as direct water spray, conductive dust, oil mist, and the ambient temperature range. Then, match these conditions against the switch’s IP67 and temperature specifications to confirm suitability. Subsequently, define your human-machine interface needs by deciding between momentary and latching function; use momentary for “jog” signals and latching for maintained “on/off” states. Also, plan the LED circuit integration for clear status indication.

Finally, verify all mechanical specifications. Ensure the panel cut-out is exactly 16mm and that the hole is cleanly deburred, as this allows the sealing ring to compress perfectly for a guaranteed seal. To unlock full performance, mount the switch in the prepared panel and tighten the nut to the specified torque using a calibrated tool. Afterward, wire the 4-pin terminals correctly by following the provided diagram, taking care to separate the LED and contact circuits properly. This meticulous approach ultimately guarantees the promised performance, safety, and service life.

Strategic Value and Future-Ready Performance

Implementing this high-grade switch offers measurable strategic advantages beyond basic functionality. Primarily, it reduces the total cost of ownership because its extended lifespan cuts replacement frequency and its high reliability prevents expensive production halts in continuous process industries. Furthermore, its built-in safety features and international certifications (CE, RoHS) actively aid compliance with stringent regulations, thereby mitigating business risk.

Industry trends further validate its relevance. As we move towards smarter, connected industry (Industry 4.0), this switch serves as a dependable manual control point, providing essential local override capability even during network disruptions. Additionally, its durable and maintenance-free design philosophy aligns with broader sustainability goals by reducing waste through longevity. Thus, specifying this component is a forward-looking decision that builds inherent resilience into your products and operations.

Conclusion: Specifying Confidence for Critical Systems

In summary, the 15A high-current 16mm metal LED push-button switch is a top-tier component that masterfully handles high power, provides extreme environmental sealing, and offers intuitive operation. Its design directly tackles core industrial challenges. Therefore, selecting this switch is a strategic investment that boosts system uptime, enhances operator safety, and reduces long-term operational costs by transforming a simple control point into a bastion of reliability.

We provide this high-performance solution to support your engineering excellence. For comprehensive technical dossiers, application-specific support, or to request evaluation samples, please contact our specialist technical team. Partner with us to integrate uncompromising reliability into your next high-power control system design.