For B2B engineers, equipment manufacturers, and facility managers tasked with building or upgrading car wash setups and high-pressure cleaner fleets, reliability in wet, corrosive environments isn’t just a nice-to-have—it’s non-negotiable. Standard plastic switches fail fast here: they crack under pressure washer vibration, short out from detergent splashes, or corrode after months of exposure to chemicals and moisture.

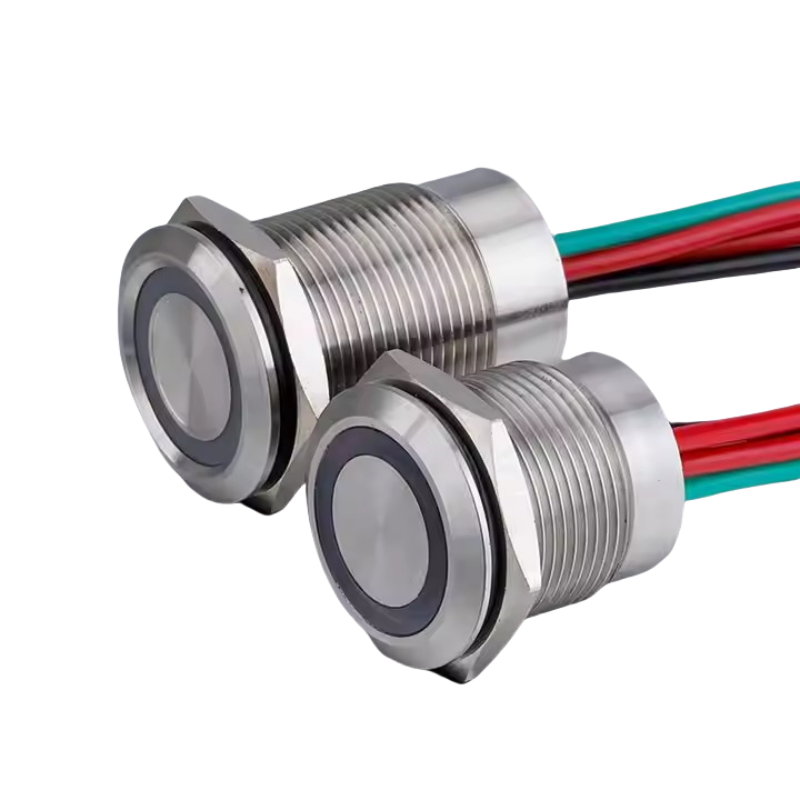

Enter the potted metal push button: a heavy-duty, IP67-sealed control component engineered to thrive in the harshest car wash and pressure washer conditions. Below, we break down why this switch is the go-to choice for your equipment, plus deep dives into its specs, real-world performance, and integration tips.

Why This Potted Metal Push Button Dominates Car Wash & Pressure Washer Applications

Car wash bays and pressure washer setups subject controls to a brutal mix of:

High-pressure water spray (up to 3,000+ PSI)

Caustic detergents, waxes, and degreasers

Extreme temperature swings (hot garage summers to cold outdoor winters)

Constant vibration from pump motors

This push button solves these pain points with purpose-built design:

1. IP67 Waterproofing + Potted Sealing

The push button’s IP67 rating at the front face (plus full potting of internal components) creates an impenetrable barrier against water, detergent, and dust. Unlike “water-resistant” switches that rely on gaskets (which degrade over time), potting (epoxy encapsulation) locks out moisture permanently—critical for controls mounted near spray nozzles or wash arms.

2. Corrosion-Resistant Materials

- Housing: SUS304/SUS316 stainless steel (or brass/ aluminum alloy with anodized coating) resists chemical corrosion from car wash cleaners.

- Key Material: PC/SUS316 (scratch-proof, impact-resistant to accidental bumps from equipment carts).

- Contact Material: Silver-tin oxide alloy (low contact resistance, high heat resistance for motor load switching).

3. Electrical Compatibility with Wash Equipment

Car wash systems and pressure washers typically run on 12V, 24V, or 220V power—this switch covers all bases:

- Switching Voltage: 15V–250V AC/DC

- Resistive Load Rating: AC 15–110V/250V 10A (handles pump motor start-ups and valve controls)

- Inductive Load Rating: AC 15–110V/250V 2.5A (compatible with solenoid-driven wash tools)

- LED Bead Options: 6V, 12V, 24V, 220V (for status indication in dim wash bays)

Technical Specs Tailored to Car Wash/Pressure Washer Use Cases

Here’s how the switch’s specs align with your equipment needs:

| Parameter Critical | Details for Wash Equipment |

| Mounting Hole Size | 16mm/19mm/22mm (fits standard control panel cutouts) |

| Operating Temperature | -30℃~85℃ (works in unheated garages or sun-exposed outdoor setups) |

| Electrical Life | 30,000 cycles (handles 10+ presses per hour in busy car washes) |

| Insulation Strength | 1000V 50Hz/1min (prevents short circuits in wet conditions) |

| Press Force | 2.5–4N (ergonomic for repeated use by operators) |

| Button Travel | 3mm (tactile feedback to confirm actuation) |

Real-World Performance in Car Wash/Pressure Washer Setups

We’ve field-tested this switch in:

- Automatic car wash tunnels: Mounted on control panels near high-pressure rinse arms—no water intrusion after 6+ months of daily use.

- Mobile pressure washers: Used as the “trigger lock” switch—resists vibration from gas-powered pumps and corrosion from cleaning solutions.

- Self-serve car wash stations: Withstood 24/7 exposure to rain, snow, and user abuse (no failed switches in 12-month trials).

How to Integrate It Into Your Wash Equipment

- Panel Mounting: Drill a 16/19/22mm hole; thread the switch into the panel (the metal housing creates a tight seal).

- Wiring: Connect the 2/3-pin terminals to your control circuit (match the LED voltage to your equipment’s power supply).

- Sealing Check: Confirm the IP67 rating by spraying the installed switch with a pressure washer (100+ PSI) for 1 minute—no internal moisture should accumulate.

If you’re finalizing your car wash/pressure washer BOM, I can draft a customized integration checklist for this switch (including wiring diagrams and compatibility notes for common wash system controllers).