In the world of electrical components, few are as widely used and trusted as the rocker switch. Known for its intuitive design and reliable performance, the rocker switch is a staple in everything from home appliances to industrial control panels. Whether you’re wiring a boat, building a custom dashboard, or setting up a DIY electronics project, understanding what a rocker switch does and how it works can help you make better choices when selecting switches for your needs.

Unlike toggle switches that require a lever motion, rocker switches operate with a simple press — one side turns the circuit on, and the other side turns it off. The flat, wide surface makes them easy to use even in low-light conditions or while wearing gloves. Many models also feature built-in LED lights to indicate whether the switch is on or off, adding both functionality and visual appeal.

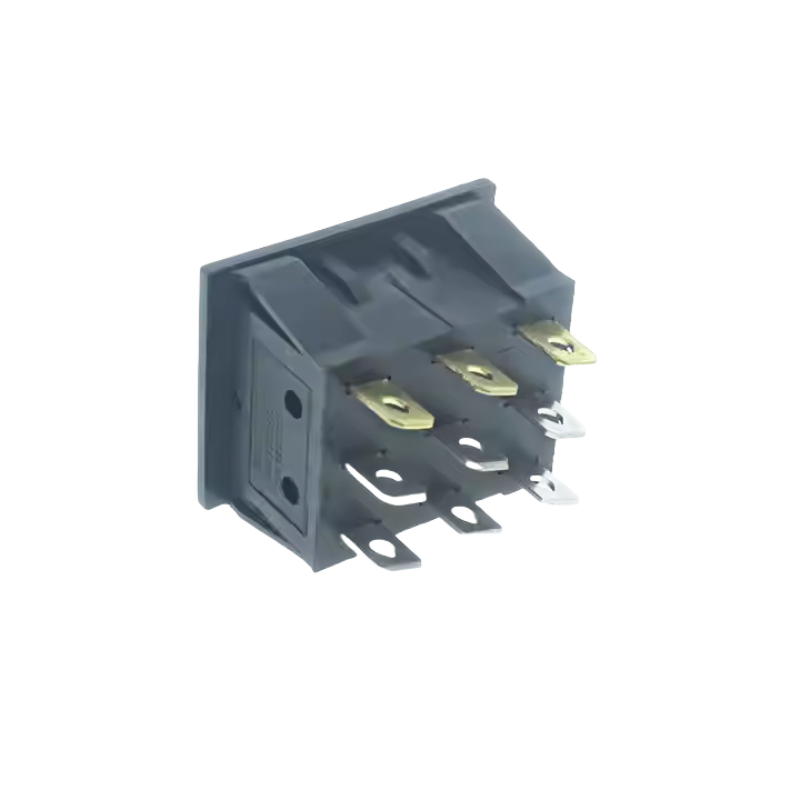

Rocker switches come in a variety of configurations to suit different applications. Some are designed for low-voltage systems like car lighting and audio equipment, while others are rated for high-current uses such as power tools and industrial machines. They can be found in SPST (single pole single throw), SPDT (single pole double throw), and DPDT (double pole double throw) arrangements, allowing for flexible wiring options depending on the complexity of the system they’re controlling.

One reason why rocker switches remain so popular is their durability. Constructed from materials like plastic, rubber, and metal, they’re built to withstand repeated use and exposure to various environmental conditions. There are even waterproof versions available, making them ideal for marine and outdoor applications where moisture might be a concern.

Installation is straightforward thanks to standardized sizes like 16mm and 19mm, which fit most panel cutouts. Once mounted, connecting the wires is usually a matter of matching terminals based on the switch’s function. This simplicity makes them a favorite among both professionals and hobbyists alike.

From kitchen appliances to emergency stop buttons on factory floors, rocker switches offer a practical solution for manual control. Their clear tactile feedback ensures users know when the switch has engaged properly, reducing the risk of accidental operation. And because they come in a range of colors and styles, they can blend seamlessly into any design — whether minimalist or rugged industrial.

Whether you’re replacing a worn-out switch or designing a new control panel, choosing the right rocker switch involves considering factors like voltage rating, current capacity, terminal type, and environmental protection. Taking the time to match these specifications to your application will ensure long-term reliability and safe operation.

As technology continues to evolve, the basic principles behind mechanical switches like the rocker switch remain unchanged. Their simplicity, dependability, and ease of use continue to make them an essential component in modern electrical systems across countless industries.