In the design and specification of components for industrial control panels, marine interfaces, and outdoor equipment, decisions are driven by a need for absolute certainty. Operators require interfaces that communicate state without ambiguity, and engineers require components that will perform as specified over the long term, despite environmental challenges. The 19mm illuminated waterproof rotary switch is a product born from these requirements. It represents a convergence of definitive switching action, integrated visual communication, and robust environmental sealing. This device is engineered not for general use, but for applications where its specific combination of features solves tangible problems in reliability, safety, and maintenance.

In the design and specification of components for industrial control panels, marine interfaces, and outdoor equipment, decisions are driven by a need for absolute certainty. Operators require interfaces that communicate state without ambiguity, and engineers require components that will perform as specified over the long term, despite environmental challenges. The 19mm illuminated waterproof rotary switch is a product born from these requirements. It represents a convergence of definitive switching action, integrated visual communication, and robust environmental sealing. This device is engineered not for general use, but for applications where its specific combination of features solves tangible problems in reliability, safety, and maintenance.

Defining the Core Engineering Principles

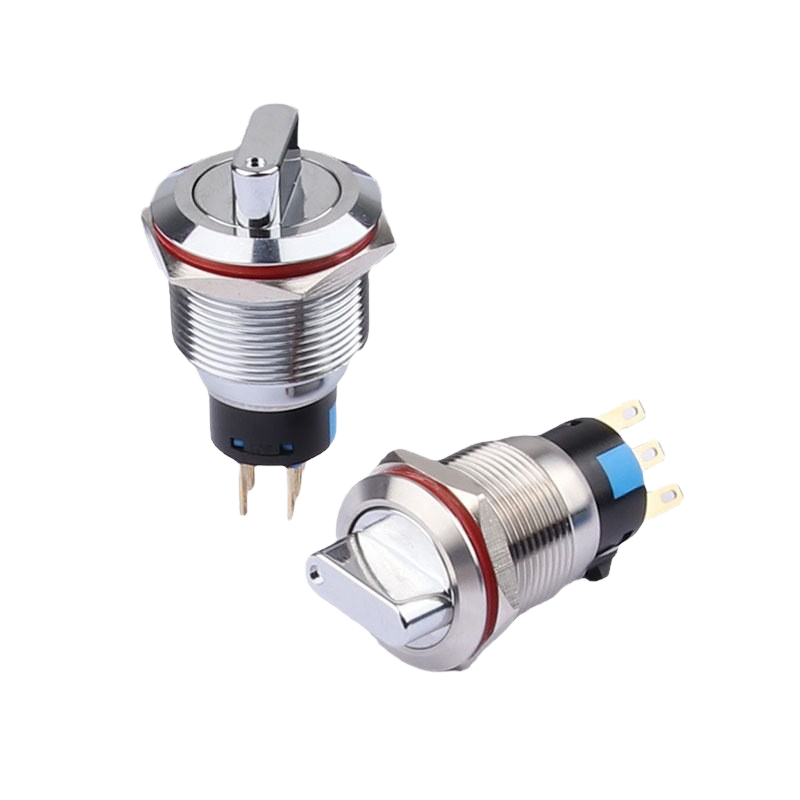

The functionality of this switch can be understood by examining its foundational design principles. The first principle is durability through material selection. The housing and shaft are constructed from stainless steel. This choice is critical in environments where corrosion is a constant threat, such as in marine applications, food processing plants, or facilities using chemical cleaners. Stainless steel provides a passive layer of protection that resists rust and degradation, ensuring the mechanical integrity of the switch body and the smooth operation of the rotating shaft over thousands of cycles. Unlike coated materials, this resistance is integral to the metal itself.

The second principle is unambiguous control through mechanical precision. This is a three-position rotary switch with a maintained, or latching, action. Internally, a spring-loaded detent mechanism engages with precision-machined grooves at each position. This engineering results in a distinct tactile and audible click with every turn. This feedback is not a minor feature; it is a fundamental safety and usability characteristic. It provides the operator with physical confirmation that the switch has fully engaged the intended circuit, eliminating the risk of resting in an intermediate, undefined state that could lead to equipment malfunction or hazard.

The third principle is integrated status indication. A 12V LED is embedded within the assembly, causing the knob itself to illuminate. This transforms the component from a simple control into a combined control-and-status device. In low-light conditions, on complex panels, or for supervisors monitoring a floor from a distance, this illumination provides immediate, at-a-glance comprehension of the system’s setting. This integration also offers a practical design advantage by eliminating the need for a separate indicator light on the panel, thereby reducing part count, wiring complexity, and required panel space.

The fourth principle is guaranteed environmental protection, quantified by the IP67 rating. This international standard defines two key capabilities. The “6” signifies complete protection against dust ingress; no particulate matter can enter the housing to interfere with electrical contacts. The “7” signifies protection against the effects of temporary immersion in water. Specifically, the switch can withstand being submerged in up to one meter of water for thirty minutes. This level of sealing is essential for equipment subjected to high-pressure washdowns, operation in driving rain, or exposure to high-humidity and condensing environments, ensuring internal components remain completely isolated from the external environment.

Application in Professional and Industrial Settings

The value of this switch is realized in specific applications where its feature set addresses clear operational challenges. In industrial automation, it is commonly specified as a machine mode selector. On a packaging line conveyor, for instance, positions for “Jog,” “Manual,” and “Automatic” allow for safe maintenance and flexible operation. The illuminated knob allows a floor manager to instantly verify the operating mode from a distance, while the IP67 seal protects the internal mechanism from dust, lint, or coolant mist pervasive in such environments.

Within marine, automotive, and mobile equipment contexts, durability and clarity under duress are paramount. This switch can be used to control auxiliary systems such as deck lighting, bilge pumps, or hydraulic power take-offs. The stainless steel construction resists corrosion from salt spray, the waterproof seal is vital for locations exposed to the elements, and the illuminated positions are critical for safe operation during night-time or in poor weather conditions where visibility is compromised.

For power management and backup systems, error prevention is the primary concern. When used as a source selector switch for a critical server rack or medical device—with positions for “Mains,” “UPS,” and “Generator”—the switch’s definitive detents and lit position prevent accidental and potentially dangerous misselection during a power transfer or maintenance event. The robust construction ensures it functions reliably even when unused for extended periods between critical events.

Technical Specifications and Integration Considerations

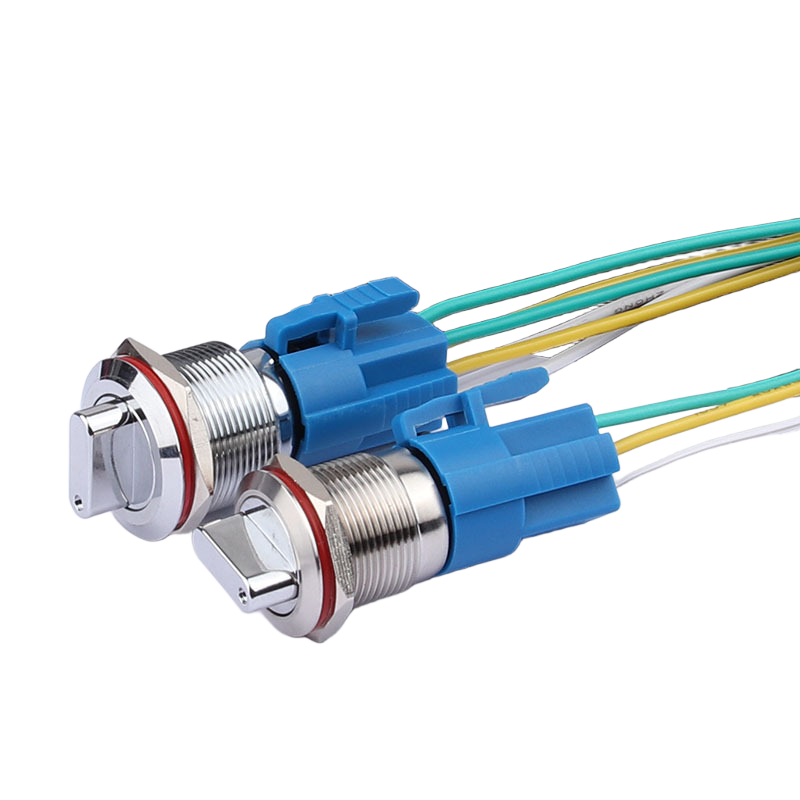

The switch is designed around a standard 19mm panel mounting diameter, requiring a clean, burr-free cutout for the integrated sealing gasket to function correctly. Typical electrical ratings for such a component include capacity for 5 amps at 125 volts AC or 3 amps at 250 volts AC, making it suitable for directly controlling relays, contactor coils, solenoid valves, and indicator circuits. The illuminated knob is typically powered by a separate 12V DC circuit, with common LED color options including red, green, amber, and blue to allow for functional color-coding within a control scheme. Termination options generally include solder lugs for direct wiring, printed circuit board pins for integrated assembly, or pre-wired cable versions to significantly reduce field installation time and potential wiring errors.

Conclusion

The 19mm illuminated waterproof rotary switch is a component defined by its purpose: to provide clear, reliable, and durable control in settings where these attributes are non-negotiable. It achieves this by synthesizing high-grade materials, precise mechanical action, integrated visual feedback, and certified environmental sealing into a single, professional-grade unit. For engineers designing systems that must operate with certainty in harsh or demanding conditions, this switch offers a resolved and dependable solution that enhances both the performance and the perceived quality of the final equipment.

For access to complete technical documentation, including detailed datasheets, certification reports, and computer-aided design model files for the 19mm illuminated waterproof rotary switch series, please refer to the product section of our website. Our technical support team is available to provide application guidance, discuss specific configuration requirements, and facilitate the sample request process.

19mm Waterproof Metal Rotary Switch 3-Position 12V LED Stainless Steel