Introduction: Why Your E-Stop Is More Than Just a Red Button

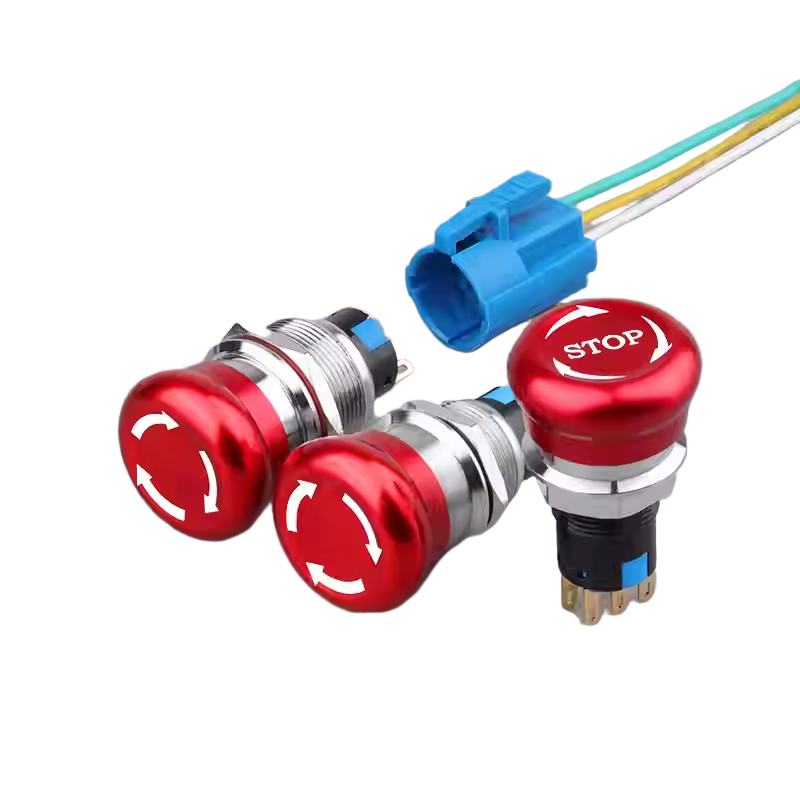

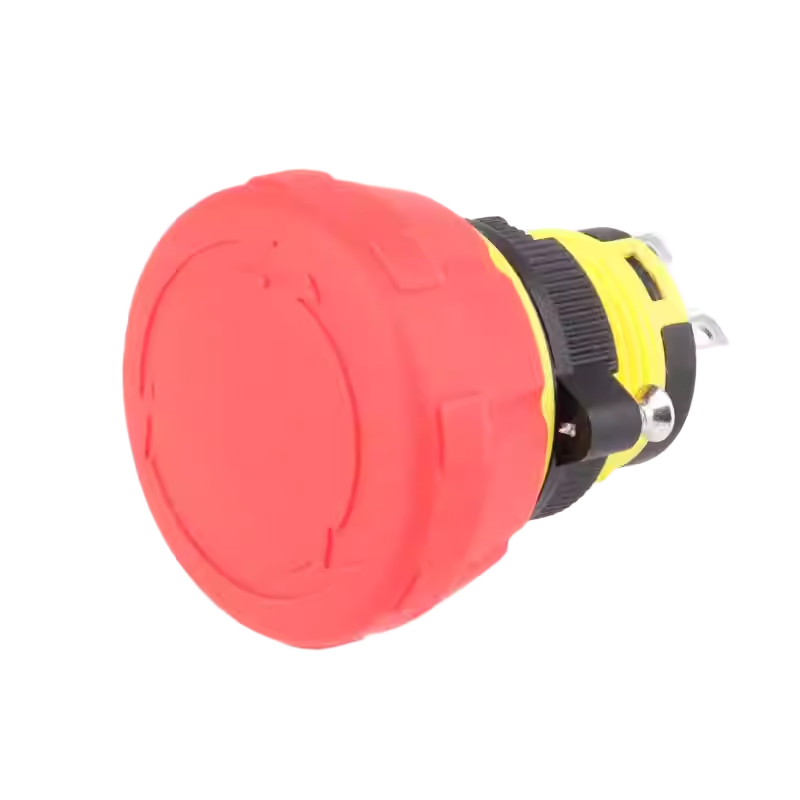

In the world of industrial machinery and CNC equipment, the emergency stop (E-Stop) isn’t merely a component—it’s your last line of defense. When seconds matter, the right E-Stop can mean the difference between a minor interruption and a catastrophic incident. Today, we’re examining why the 19mm Mushroom Head Waterproof Metal Emergency Stop Switch represents the gold standard for industrial safety applications.

The Non-Negotiable Requirements for Machinery E-Stops

Before diving into specifications, let’s establish what every safety engineer knows about machinery E-Stops:

Instantaneous Activation: Must be immediately accessible and operable

Unmistakable Identification: High-visibility red mushroom head

Positive Action: Requires deliberate reset to prevent accidental restart

Environmental Resilience: Must function reliably in harsh conditions

Electrical Reliability: Consistent performance over thousands of cycles

Why the 19mm Metal Mushroom Head Switch Excels

1. Physical Design for Emergency Situations

The mushroom head design isn’t just for aesthetics. Its large surface area (compatible with 19mm panel cutouts) allows for:

Palm-strike activation even with gloved hands

360-degree accessibility from any approach angle

Positive tactile feedback ensuring the operator knows activation has occurred

2. Built for Industrial Environments

IP55 Waterproof Rating at Button Interface: Resists coolant splash, oil mist, and washdown procedures common in machining environments

Metal Housing Options: Choose between SUS304 stainless steel (corrosion-resistant), nickel-plated brass (conductive grounding), or anodized aluminum (lightweight durability)

-30°C to +85°C Operating Range: Functions reliably in unheated warehouses or near heat-generating equipment

3. Electrical Performance That Matters

For CNC and industrial machinery, electrical specs aren’t just numbers—they’re safety assurances:

| Parameter | Why It Matters for Machinery |

|---|---|

| 3A @ 250VAC Resistive | Handles control circuit loads directly |

| 0.75A Inductive Load Rating | Safely breaks motor contractor coils without welding |

| ≤50mΩ Contact Resistance | Ensures reliable circuit completion over time |

| 500,000 Electrical Cycles | Outlasts typical machinery service intervals |

Configuration Options: SPST vs. SPDT

3-Pin SPST (Single Pole Single Throw)

Ideal for: Simple safety circuits that break a single control line

Typical Use: Direct series connection in safety relay circuits

Advantage: Simpler wiring, lower cost

6-Pin SPDT (Single Pole Double Throw)

Ideal for: Advanced safety systems requiring dual-circuit monitoring

Typical Use: Safety circuits with cross-monitoring, where both NO and NC contacts are monitored by a safety controller

Advantage: Provides diagnostic capability—controller can detect contact welding or switch failure

Installation Best Practices for Machinery Integration

1. Mounting Considerations

Ensure the 19.0-19.1mm panel hole is clean and burr-free

Position within 600mm of the operator’s normal working position (ISO 13850 requirement)

Consider multiple units for large machines with multiple workstations

2. Wiring Recommendations

Use the quick-connect .250″ (6.35mm) terminals for secure connections

Implement dual-channel safety circuits when using SPDT configuration

Always test circuit functionality after installation

3. Integration with Safety Systems

Connect to category 3 or 4 safety circuits (ISO 13849-1)

Consider latching (self-locking) version to prevent automatic restart

Implement manual reset requiring deliberate twist/pull action

Real-World Application Scenarios

CNC Machining Centers

Mount on control pendant and machine enclosure

Use SPDT configuration for dual-channel safety monitoring

Select SUS304 housing for coolant resistance

Industrial Presses & Stamping Machines

Position at multiple operator stations

Implement rope-operated E-Stops for large machines

Choose high-visibility red with yellow background ring

Robotic Work Cells

Install on safety fencing at access points

Use latching version to maintain stop state until deliberately reset

Consider LED-illuminated versions for low-light areas

Maintenance & Testing Protocol

Even the most robust E-Stop requires verification:

Weekly Functional Test: Activate and verify machine response

Monthly Visual Inspection: Check for physical damage or contamination

Annual Electrical Testing: Verify contact resistance and insulation values

5-Year Replacement Cycle: Consider proactive replacement based on mechanical life (1,000,000 cycles)

Beyond Compliance: Creating a Safety Culture

The right E-Stop contributes to broader safety objectives:

Operator Confidence: Knowing the E-Stop works reliably encourages proper use

Reduced Downtime: Reliable switches mean fewer false trips and quicker recovery

Regulatory Compliance: Meets requirements of ISO 13850, IEC 60947-5-1, and machine-specific standards

Insurance & Liability: Proper safety components support compliance documentation

Conclusion: Your Safety Deserves This Level of Engineering

In industrial machinery and CNC equipment, compromise on safety components is never an option. The 19mm Mushroom Head Waterproof Metal Emergency Stop Switch provides:

✅ Immediate, reliable activation when every second counts

✅ Industrial-grade durability for harsh environments

✅ Flexible configuration for any safety architecture

✅ Long-term reliability through 1,000,000 mechanical cycles

When you specify this switch, you’re not just buying a component—you’re investing in a safety system that protects your people, your equipment, and your productivity.

Need help integrating the right E-Stop into your machinery design? Contact our safety engineering team for application-specific guidance and compliance support.