From circuit breakers to spacecraft controls, metal push button switches are engineered for precision. This blog dives into their design principles, material science, and testing standards.

1. Material Selection: Why Metal Matters

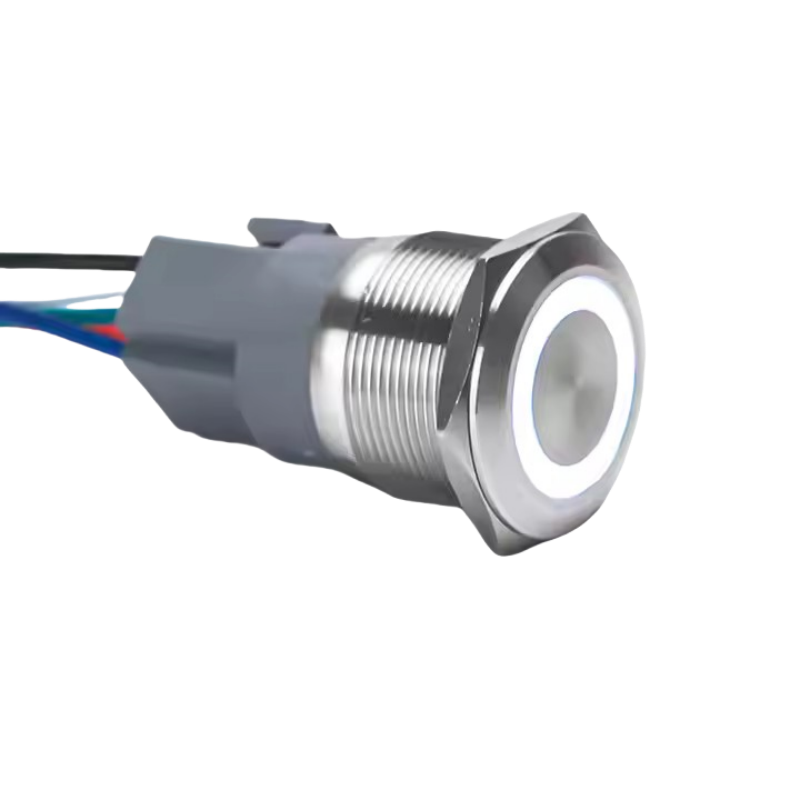

a. Stainless Steel

Corrosion-resistant, ideal for marine or chemical environments.

Grades: 304 (general use) vs. 316 (high corrosion resistance).

b. Aluminum

Lightweight and conductive, perfect for aerospace.

Anodized finishes for added durability.

c. Brass

Excellent electrical conductivity, often used in low-voltage systems.

Polished finishes for decorative applications.

2. Design Considerations

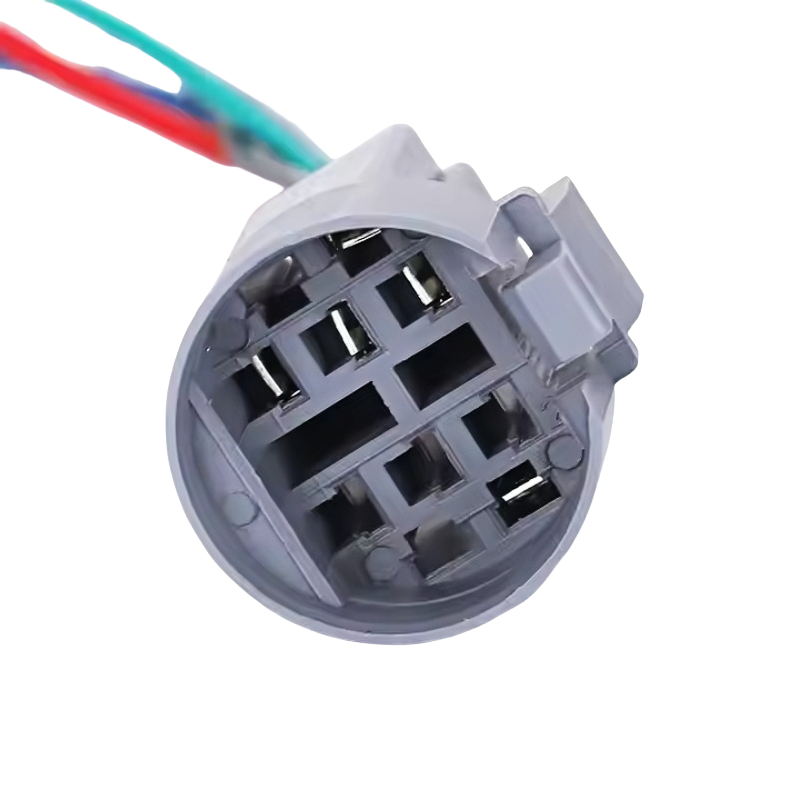

a. Contact Mechanism

Gold-Plated Contacts: Reduce oxidation and ensure signal integrity.

Snap-Action Design: Provides tactile feedback and minimizes arcing.

b. Sealing Techniques

O-rings or silicone gaskets for waterproofing.

Hermetic sealing for vacuum or high-pressure environments.

c. Actuation Force Optimization

Ranges from 2N (light touch) to 20N (anti-accidental presses).

Custom springs for tailored user experience.

3. Compliance and Testing Standards

IP Ratings: IP67 (dustproof and waterproof up to 1m).

UL/CE Certification: Ensures safety for electrical components.

Mil-Spec Testing: Vibration, shock, and temperature cycling (-40°C to 125°C).

Case Study: A railway switch tested for 10 million cycles under extreme temperatures.

4. Innovations in Metal Switch Technology

Smart Switches: IoT-enabled buttons with wireless connectivity.

Haptic Feedback: Simulates touch response in automotive controls.

Eco-Friendly Materials: Recyclable aluminum housings.

The engineering of metal push button switches blends tradition and innovation, ensuring they meet evolving industrial demands.