In an era dominated by touchscreens and capacitive sensors, the enduring reliability of metal push button switches continues to redefine industrial resilience. These electromechanical marvels bridge the gap between human intention and machine response through principles refined over a century. Unlike their plastic counterparts, metal switches leverage the inherent properties of marine-grade stainless steel, electroplated brass, and aerospace aluminum alloys to conquer environments where lesser components fail catastrophically.

The Metallurgical Advantage

The core robustness stems from molecular engineering. Take 316L stainless steel – its chromium-nickel-molybdenum matrix forms a passive oxide layer that regenerates when scratched. This self-healing capability allows switches to withstand 15,000+ hours of salt spray testing (per ASTM B117) without contact degradation. Meanwhile, brass actuators plated with 5μm hard gold over nickel achieve <10mΩ contact resistance after 1 million cycles, outperforming polymer switches by orders of magnitude. The secret lies in gold’s electron configuration: Its half-filled 6s orbital enables electron flow with minimal lattice scattering, reducing Joule heating even at 10A loads.

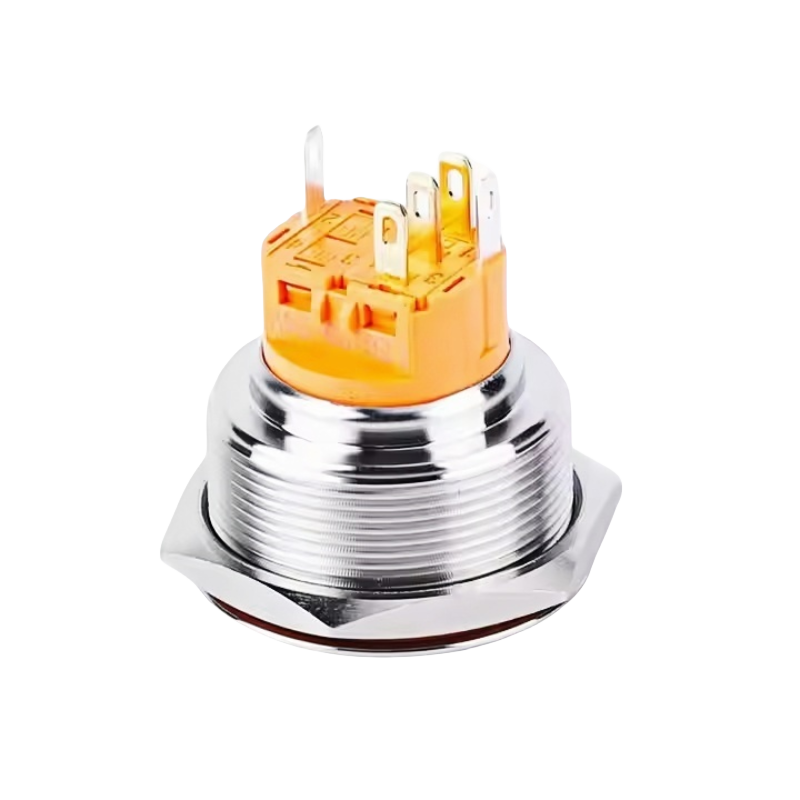

Precision Mechanics in Action

Inside a sealed switch body, the over-center snap mechanism operates like a microscopic trebuchet. When force exceeds 2.5N, a beryllium copper spring crosses its instability point, generating tactile feedback within 0.3ms. This snap-action isn’t just about user experience – it eliminates partial contact arcing by ensuring contacts slam together at >0.5m/s. Advanced designs incorporate magnetic arc suppression where neodymium fields stretch plasma paths, quenching arcs 40% faster than conventional designs. Combined with hermetically sealed nitrogen-filled chambers, these switches achieve IP69K ratings while maintaining 100,000-cycle lifespans in foundries and food processing plants.

Cutting-Edge Applications

Offshore drilling rigs deploy explosion-proof variants with triple-sealed shafts and intrinsically safe circuits that prevent methane ignition at 0.02mJ energy levels. In contrast, medical linear accelerators use titanium-bodied switches with non-magnetic properties to avoid distorting radiation fields during cancer therapy. The latest innovation comes from high-speed rail systems: Switches with piezoelectric feedback sensors now detect actuator wear before failure by monitoring resonant frequency shifts as small as 0.07Hz.

The Sustainability Equation

While plastic switches generate 8.2kg CO₂ per kg manufactured, metal switches leverage >92% recycled content. A single stainless steel switch can replace 30 plastic units over equipment lifetime, reducing landfill waste by 97%. Moreover, modular contact cartridges enable component-level replacement – users swap worn silver-cadmium oxide contacts without discarding the entire assembly, slashing maintenance costs by 60%.