Rocker switches are one of the most versatile and widely used components in electrical and electronic systems. From automotive applications to industrial machinery, these switches play a critical role in controlling circuits with their simple yet effective design. This article explores the fundamentals of rocker switches, their types, applications, and key considerations when selecting the right switch for your project.

What is a Rocker Switch?

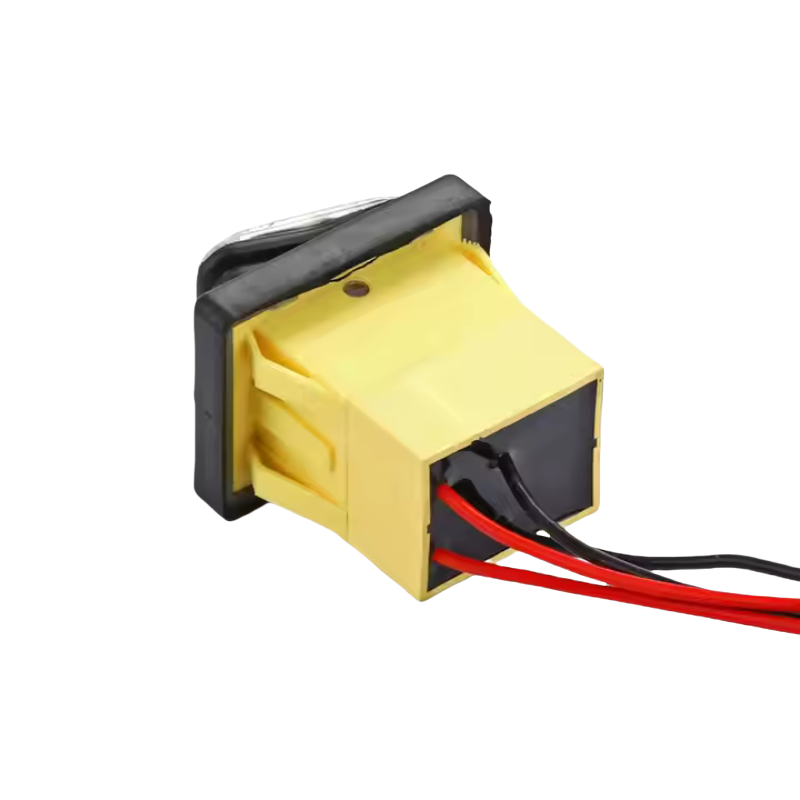

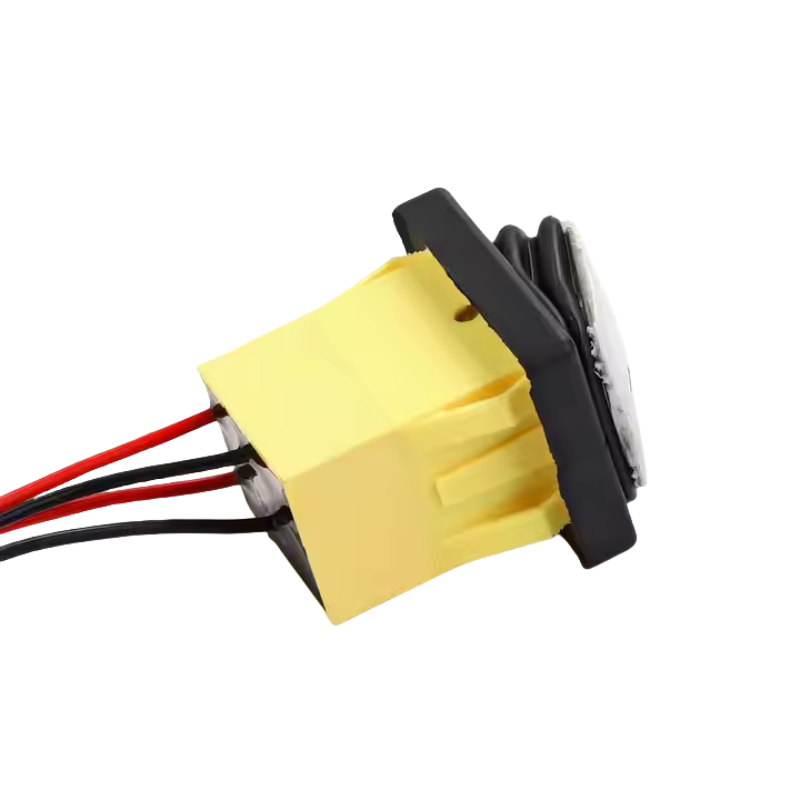

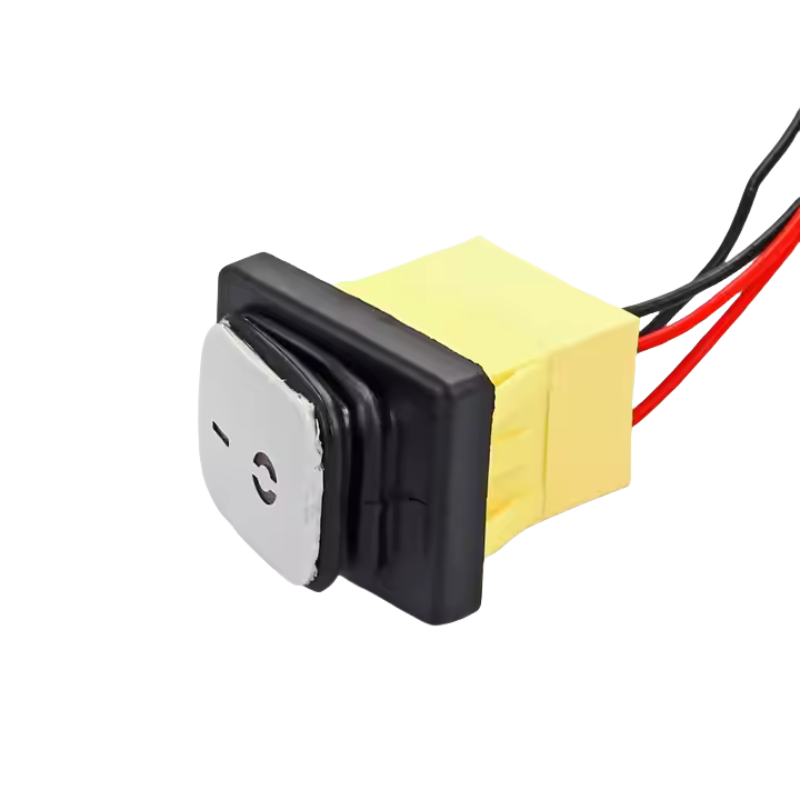

A rocker switch is a type of electrical switch that toggles between on and off positions by pressing either side of a pivoting lever (the “rocker”). Unlike traditional toggle switches, which require a knob to flip up or down, rocker switches operate by pushing the center of the lever in either direction. This design makes them user-friendly, durable, and suitable for environments where space is limited.

Rocker switches are commonly used in devices that require frequent switching, such as home appliances, automotive systems, and industrial equipment. Their compact size and ease of operation make them ideal for both consumer and professional applications.

How Rocker Switches Work

At its core, a rocker switch functions as a single-pole double-throw (SPDT) or double-pole double-throw (DPDT) switch, depending on its configuration. Here’s a breakdown of the basic operation:

- SPDT Rocker Switch:

- Connects one input to one of two outputs.

- Example: Turning a light on/off or switching between two power sources.

- DPDT Rocker Switch:

- Controls two separate circuits simultaneously.

- Example: Reversing the direction of a motor or switching between two pairs of devices.

When the switch is pressed, the internal contacts open or close, allowing or interrupting the flow of electricity. The switch’s pole and throw configuration determines how many circuits it can control and how many positions it can occupy.

Types of Rocker Switches

Rocker switches come in various designs to suit different needs. Here are the most common types:

- Standard Rocker Switches

- Basic on/off functionality with no additional features.

- Ideal for simple applications like lighting or power control.

- Illuminated Rocker Switches

- Include an LED or incandescent light to indicate the switch’s status.

- Useful in low-light environments (e.g., automotive dashboards or marine equipment).

- Momentary Rocker Switches

- Only maintain the on position while being pressed.

- Common in devices requiring temporary activation, such as doorbells or test buttons.

- Waterproof Rocker Switches

- Sealed against dust and moisture (often rated IP64 or higher).

- Essential for outdoor use, boats, or industrial settings with high humidity.

- Carling-Style Rocker Switches

- A premium design with a robust build and tactile feedback.

- Popular in automotive, aviation, and heavy-duty machinery due to their durability.

- Keyed Rocker Switches

- Require a specific key to operate, adding a layer of security.

- Used in access-controlled systems like vending machines or security panels.

Key Features and Specifications

When selecting a rocker switch, consider the following parameters to ensure compatibility with your application:

- Voltage and Current Ratings

- Ensure the switch can handle the maximum voltage and current of your circuit.

- Example: A 12V 20A switch is suitable for automotive lighting systems.

- Pole and Throw Configuration

- Choose SPDT or DPDT based on the number of circuits you need to control.

- Mounting Style

- Panel-mount switches are fixed into a surface (e.g., dashboards or control panels).

- PCB-mount switches are soldered directly onto a printed circuit board.

- Material and Durability

- High-quality materials like ABS plastic or metal alloys enhance longevity.

- Look for switches with corrosion-resistant coatings for harsh environments.

- IP Rating

- Indicates resistance to dust and water. For example:

- IP64: Protected against dust and splashing water.

- IP67: Protected against immersion in water up to 1 meter for 30 minutes.

- Indicates resistance to dust and water. For example:

- Terminal Type

- Screws, push-in terminals, or quick-connect options determine ease of installation.

Applications of Rocker Switches

Rocker switches are indispensable in a wide range of industries. Here are some of their most common applications:

- Automotive Industry

- Use Case: Controlling headlights, wipers, power windows, or custom audio systems.

- Example: Waterproof Carling-style switches are used in motor boats and trailers to manage lights and auxiliary equipment.

- Industrial Machinery

- Use Case: Starting/stopping motors, conveyor belts, or pumps.

- Example: DPDT switches reverse the direction of a motor in manufacturing lines.

- Marine Systems

- Use Case: Operating bilge pumps, navigation lights, or trolling motors.

- Example: Dual-voltage (12V/24V) switches ensure compatibility with diverse marine electrical systems.

- Home Automation

- Use Case: Smart home devices, HVAC systems, or security panels.

- Example: Momentary switches activate garage door openers or sprinkler systems.

- Aerospace

- Use Case: Controlling avionics, cabin lighting, or emergency systems.

- Example: Illuminated switches with tactile feedback are critical for cockpit operations.

- Consumer Electronics

- Use Case: Power buttons for appliances like coffee makers, microwaves, or gaming consoles.

- Example: Compact SPDT switches fit into small devices like portable speakers.

Why Choose Rocker Switches Over Other Switches?

Rocker switches offer several advantages over alternatives like toggle or push-button switches:

- User-Friendly Design

- The large, flat surface requires minimal force to operate, reducing strain.

- Durability

- Fewer moving parts compared to toggle switches, minimizing wear and tear.

- Space Efficiency

- Compact size makes them ideal for tight spaces in control panels or enclosures.

- Versatility

- Available in configurations for single, dual, or even multi-position switching.

- Safety

- Waterproof and flame-resistant models meet safety standards for hazardous environments.

How to Select the Right Rocker Switch

Choosing the optimal switch involves evaluating your project’s requirements. Follow these steps:

- Determine Electrical Needs

- Calculate the required voltage, current, and circuit configuration (SPDT/DPDT).

- Assess Environmental Conditions

- For outdoor or high-moisture areas, select a waterproof switch with an appropriate IP rating.

- Consider User Interaction

- For frequent use, choose a switch with tactile feedback and clear labeling.

- Check Compatibility

- Ensure the switch fits your mounting space and terminal connections.

- Prioritize Quality and Certifications

- Look for switches with CE, UL, or RoHS certifications for reliability and safety.

Maintenance and Troubleshooting

To prolong the lifespan of your rocker switch:

- Regular Inspection

- Check for signs of wear, corrosion, or loose connections.

- Clean Contacts

- Use isopropyl alcohol and a soft brush to remove dust or debris from internal contacts.

- Avoid Overloading

- Do not exceed the switch’s voltage/current rating, as this can cause overheating or failure.

- Replace Faulty Switches

- If a switch becomes unresponsive or damaged, replace it immediately to prevent system malfunctions.

Case Study: Rocker Switches in Industrial Automation

In a recent collaboration between Extech Solutions and Rockwell Automation, waterproof DPDT rocker switches were integrated into a glass manufacturing plant’s control system. The switches replaced manual controls for temperature regulation and conveyor belt direction, enabling automated processes. By using AI-driven algorithms, the system optimized energy efficiency and reduced defects by 15%. The success of this project highlights how modern rocker switches can bridge the gap between traditional controls and smart manufacturing.