Your operations demand unwavering reliability; meanwhile, component failure remains a persistent threat to productivity and profit. Indeed, the integrity of complex equipment often hinges on the smallest control interfaces. Consequently, strategic procurement must look beyond primary machinery to the foundational components that enable it. Specifically, the modern electronic switch serves as far more than a basic connector; fundamentally, it operates as the critical nerve center for control, safety, and efficiency. Therefore, selecting a superior switch is a direct investment in operational resilience. This discussion details how advanced electronic switching solutions address core industrial challenges. We will explore their engineered properties, demonstrate their pivotal role through concrete industry applications, and outline a strategic selection process. Ultimately, this knowledge empowers you to specify components that enhance your product’s value and ensure long-term performance.

Your operations demand unwavering reliability; meanwhile, component failure remains a persistent threat to productivity and profit. Indeed, the integrity of complex equipment often hinges on the smallest control interfaces. Consequently, strategic procurement must look beyond primary machinery to the foundational components that enable it. Specifically, the modern electronic switch serves as far more than a basic connector; fundamentally, it operates as the critical nerve center for control, safety, and efficiency. Therefore, selecting a superior switch is a direct investment in operational resilience. This discussion details how advanced electronic switching solutions address core industrial challenges. We will explore their engineered properties, demonstrate their pivotal role through concrete industry applications, and outline a strategic selection process. Ultimately, this knowledge empowers you to specify components that enhance your product’s value and ensure long-term performance.

Engineered for Demands: Defining Characteristics of Robust Switches

Firstly, modern electronic switches are designed to deliver consistent performance under duress. Their architecture prioritizes endurance above all else. For instance, premium switches are rigorously tested for millions of reliable actuations. This exceptional lifespan is crucial for automated systems where frequent use is guaranteed and maintenance access is limited. Subsequently, this durability is reinforced by advanced environmental sealing. Many models achieve high ingress protection ratings, which defend against contaminants like dust, oils, and moisture. Consequently, equipment in challenging sectors such as agriculture, marine, or food processing maintains functionality where standard components would fail.

Furthermore, electrical precision and integrated protection are equally vital. These switches provide stable current management and accurate signal transmission, which is essential for sensitive calibration equipment or precision motion control. Additionally, they incorporate built-in safeguards against voltage spikes, overloads, and short circuits. As a result, they proactively protect both the switch and the more valuable connected assets, thereby preventing costly secondary damage and reducing system-wide downtime. Moreover, their design supports streamlined manufacturing, often featuring compatibility with automated assembly processes. This ensures consistent quality and facilitates efficient high-volume production for your own products.

Application in Action: Solving Real-World Industry Challenges

To illustrate their impact, consider specific sector applications. Within Industrial Automation and Machinery, reliability dictates throughput. Here, switches are deployed in motor control centers, robotic arm interfaces, and safety interlock systems. For example, a sealed, high-vibration-resistant switch on a CNC machine ensures uninterrupted operation despite constant motion and potential coolant exposure. This directly preserves production schedules and protects capital investment.

Conversely, the Commercial and Facility Management sector leverages intelligence for efficiency. Modern building systems utilize programmable switches for sophisticated control sequences. In a large warehouse, for instance, networked switches can manage high-bay LED lighting zones, activating them only in areas with occupant movement detected by sensors. This strategy significantly cuts energy costs while maintaining safety. Similarly, in a public water treatment plant, robust switches control pump systems and alarm panels, offering fail-safe operation critical for public infrastructure.

Similarly, the Consumer Technology and IoT Device market depends on refined user interaction. The tactile interface of a high-end smart home device or medical ventilator is paramount. In these applications, the switch must deliver precise actuation feel, acoustic feedback, and flawless reliability that aligns with the product’s brand promise. Moreover, options for custom illumination, actuation force, or compact form factors allow designers to differentiate their products in a competitive marketplace through superior user experience.

Selecting Your Strategic Component: A Guided Process

Navigating the selection process requires a structured approach. Initially, you must define the electrical parameters, including load type, voltage, and current requirements. Subsequently, assess the physical environment, factoring in temperature extremes, potential chemical exposure, and necessary ingress protection ratings. Finally, consider the user interface needs, such as desired tactile feedback, operational lifespan in cycles, and any aesthetic or branding integrations.

Engaging with a technical expert early accelerates this process. A proficient partner analyzes your total application profile rather than just a single specification. They can recommend solutions that balance performance, durability, and cost-effectiveness for your specific use case. Therefore, this collaborative approach de-risks the design phase and optimizes the final product’s reliability and user satisfaction.

Conclusion: Specifying for Superior Performance

In summary, specifying a high-performance electronic switch is a decisive step toward product excellence. It transforms a simple control function into a source of durability, intelligence, and competitive advantage. We encourage you to view this component not as a commodity, but as a vital contributor to your operational success.

Our team specializes in providing robust, application-tested electronic switching solutions engineered for real-world demands. We offer the technical partnership to integrate unwavering reliability into your designs. To discuss how our precision electronic switches can solve your specific application challenges, contact our engineering team today for a detailed consultation.

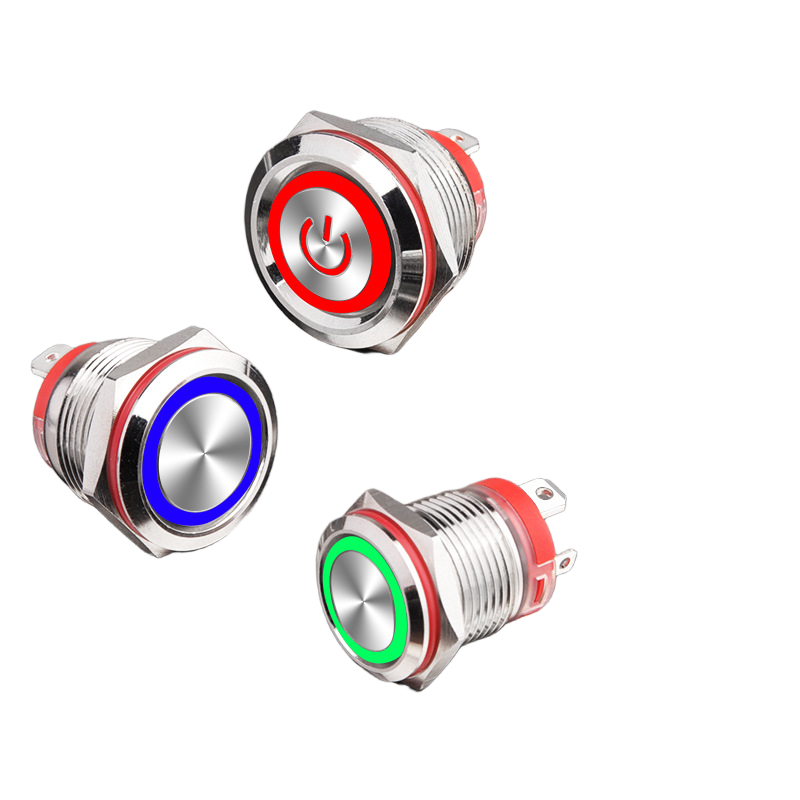

16mm/19mm/22mm Stainless Steel Key Switch – 2/3 Position, IP65, 3A Max (Industrial Grade)