We marvel at complex machines: the roar of a jet engine, the precision of a robotic arm, the silent power of a data center. Yet, nestled within these technological titans, often overlooked, lies a humble component wielding disproportionate power: the metal push button switch. This isn’t just about turning things on or off; it’s about the fundamental relationship between human intention, system integrity, and the critical concept of trust. This post delves into the profound role these switches play as the ultimate arbiters of safety and the gatekeepers of human confidence in complex systems.

Beyond the Click: The Weight of Responsibility

A metal push button switch is rarely just an electrical component. It’s a deliberate interface point between the organic, sometimes fallible, human operator and the deterministic, yet potentially dangerous, machine or system. Consider:

Emergency Stop (E-Stop): The iconic red mushroom button. Its sole purpose is to override all logic, all processes, and bring a system to the safest possible state instantly. Its metal construction ensures durability under panic-induced force. Its color and shape are globally standardized for instant recognition. The trust we place in that single button – that it will work, every single time – is paramount. Lives depend on it.

Machine Initiation/Confirmation: The green “Start” button on industrial equipment. Pressing it signifies the operator has verified safety guards are in place, personnel are clear, and the system is ready. The switch’s positive actuation and tactile feedback provide tangible confirmation of intent. Its metal housing resists accidental bumps or environmental damage that could cause unintended starts.

Critical System Overrides: In aerospace, power generation, or process control, buttons authorize bypasses, activate backups, or confirm critical actions. Their robust metal construction withstands vibration, temperature extremes, and contaminants. Their design often includes positive indication (LEDs, mechanical flags) and sometimes guards or dual-action mechanisms to prevent accidental activation. The operator trusts that activating this switch will perform exactly the defined function reliably.

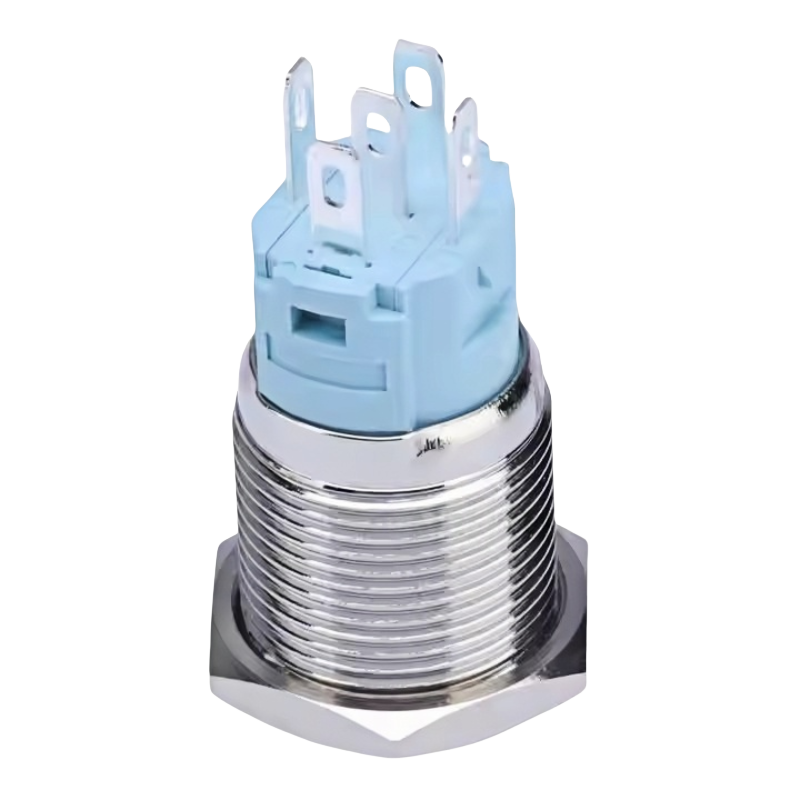

Engineering for Absolute Reliability: The Metal Advantage

Why metal? Plastic buttons have their place, but for critical applications, metal reigns supreme due to inherent properties crucial for safety and trust-building:

Mechanical Integrity: Resists impact, crushing force (panic stops), and wear far better than plastic. A bent plastic actuator might fail; a metal one likely won’t.

Environmental Resilience: Impervious to UV degradation, most solvents, oils, and extreme temperatures (-40°C to +100°C+ common). Essential for harsh industrial, marine, or outdoor settings.

Electrical Shielding: Metal housings provide inherent EMI/RFI shielding, protecting the sensitive switching mechanism inside from electrical noise that could cause false signals or interference – a critical factor in avionics or medical equipment.

Secure Mounting: Metal threads allow for extremely secure panel mounting, resisting loosening from vibration, crucial in vehicles or machinery.

Contact Reliability: High-quality metal contacts (often gold-plated silver alloy) ensure low resistance, minimal arcing, and long-term reliability, even after millions of cycles. Contact welding is a critical failure mode prevented by appropriate contact materials and designs within metal switches.

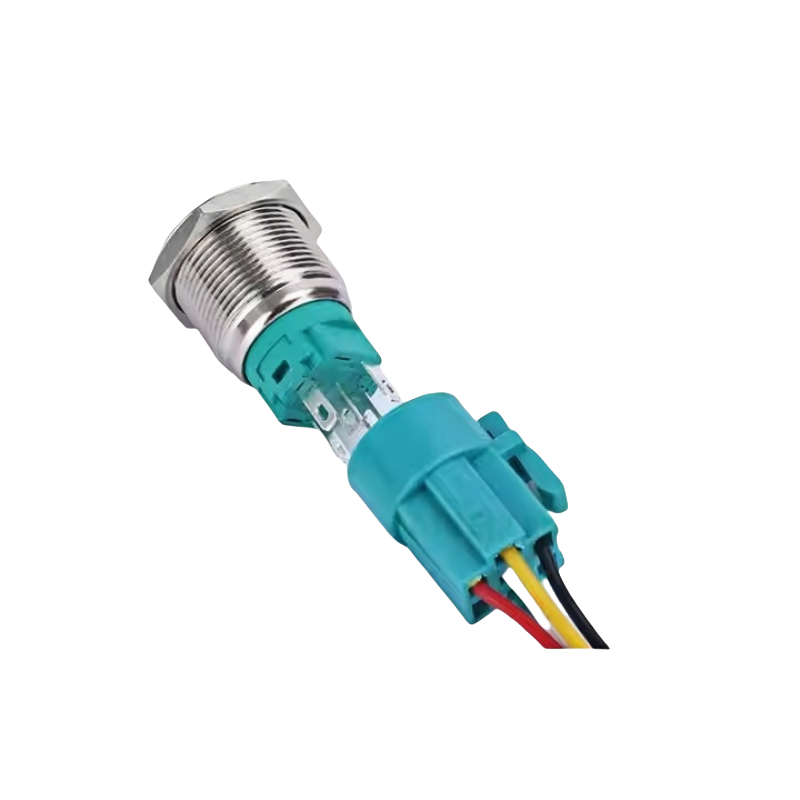

Tactile Certainty: Precision-engineered metal springs and plungers deliver consistent, unmistakable actuation force and travel (“breakpoint”), providing unambiguous feedback to the operator. This tactile language confirms the command has been registered.

The Psychology of the Metal Switch: Building Trust

The physicality of a metal switch contributes significantly to operator trust:

Perceived Durability: Its weight, solid feel, and cold touch convey ruggedness and permanence. It feels like it can take punishment and keep working. A plastic button might feel cheap or fragile in comparison for a critical function.

Auditory and Tactile Feedback: The distinct, often louder “click” of a metal switch (compared to many silent membrane switches) provides auditory confirmation. Combined with the precise tactile bump, it creates a multi-sensory assurance that the action has been taken.

Visual Distinction: Metal switches, especially with colored actuators (red, green, yellow), stand out visually. Their presence signifies importance. A guarded metal switch looks like something that shouldn’t be pressed lightly.

Deliberate Action Required: The inherent actuation force of a good metal switch (often 3-5N or more) prevents accidental activation from a stray brush or dropped tool. This intentionality barrier reinforces the seriousness of the action.

Case Studies: Where Trust and Metal Meet

Nuclear Power Plant Control Room: Every button initiating a safety-critical sequence or scram (emergency shutdown) is a robust, often guarded, metal switch with multiple layers of redundancy and fail-safe design. Operators undergo rigorous training, and their trust in these interfaces is non-negotiable. A single switch failure could have catastrophic consequences.

Surgical Robotics: Buttons controlling instrument movement, energy delivery, or camera focus must provide absolute tactile certainty to the surgeon, often operating under magnification without direct haptic feedback. Metal switches offer the precise, reliable feedback needed. Trust in the interface is trust in the procedure’s success.

Heavy Construction Machinery: Inside a vibrating excavator cab, amidst dust and potential impacts, the operator relies on large, brightly colored metal switches for critical functions like hydraulic lockout or boom movement. Their resilience and clear feedback build confidence in hazardous environments.

The Cost of Failure: When Trust is Broken

Failure of a critical metal push button isn’t just an inconvenience; it erodes trust and can lead to disaster:

Physical Failure: Bent plunger, broken spring, welded contacts – rendering the switch inoperable.

Electrical Failure: Contamination causing short circuits, corrosion increasing resistance, EMI causing false signals.

Human Factors Failure: Poor placement, unclear labeling, inadequate feedback leading to operator error.

These failures shatter the operator’s trust in the system, potentially leading to hesitation, improper procedures, or accidents. The robust design of metal switches is a direct countermeasure to these risks.

The metal push button switch transcends its simple electromechanical function. In critical applications, it is the embodiment of a safety contract between the human and the machine. Its metal construction isn’t just about longevity; it’s about providing the physical, sensory, and psychological cues necessary to build and maintain absolute trust. It ensures that when a human makes a deliberate, critical decision – to stop, to start, to override – the system responds reliably and unambiguously. In a world of increasing automation and complexity, the humble metal push button remains a vital, tangible anchor point for human control and responsibility – the unsung arbiter upon which safety and confidence ultimately rest.