A metal push button switch is a common type of manual electrical switch used to control circuits. Unlike plastic switches, it features a durable metal housing that offers better resistance to wear, impact, and environmental factors.

This makes it suitable for use in many demanding applications, from industrial machines and automotive systems to marine equipment and home electronics.

In this guide, we will explore the basics of metal push button switches — what they are, how they work, their types, and where they are commonly used.

What Is a Metal Push Button Switch?

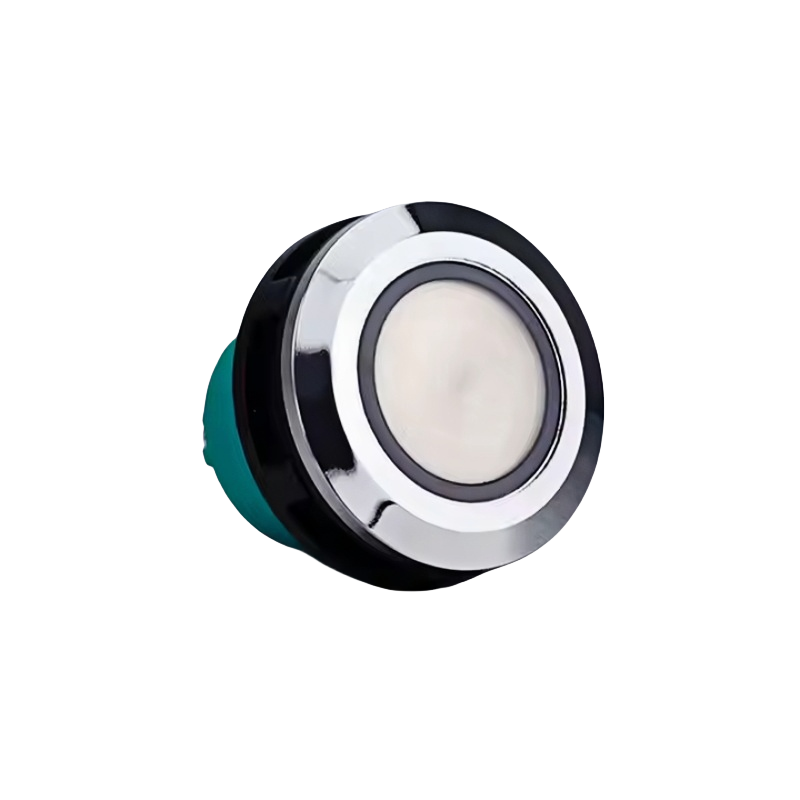

A metal push button switch is an electromechanical device designed to open or close an electrical circuit when pressed. The switch has a metal body, usually made of stainless steel, brass, or aluminum, which gives it strength and long-term durability.

It typically includes a spring mechanism that controls how the switch returns to its original position after being pressed.

The most common sizes include 16mm, 19mm, 22mm, and 30mm, which are based on the diameter of the mounting hole required in a panel or enclosure.

These switches can be found with or without LED lights, and may offer different functions such as momentary action or latching (on/off toggle).

How Do They Work?

At its core, a metal push button switch works by pressing the button to move internal contacts into place. When the button is released, a spring pushes it back to its starting position — unless it is a latching switch.

There are two main operating modes:

- Momentary: The switch only works while the button is held down. Once released, the circuit opens.

- Latching: Each press toggles the switch between ON and OFF states. It remains in the new state until pressed again.

Some models also come with indicator lights (LEDs) to show the current status of the switch.

Common Types of Metal Push Button Switches

Metal push button switches are available in various types to suit different needs.

1. By Function

- Momentary: For temporary actions like starting a machine.

- Latching: For continuous operation like turning a light on or off.

2. By Contact Type

- Normally Open (NO): The circuit is open until the button is pressed.

- Normally Closed (NC): The circuit is closed until the button is pressed.

These contact types are important in safety systems, such as emergency stop buttons, which are often NC to cut power when pressed.

3. By Illumination

- Non-Illuminated: Simple design without any light.

- LED Illuminated: Includes dot LEDs or ring LEDs for visibility, especially useful in low-light environments.

4. By Environmental Protection

Many metal push button switches are built to resist water and dust. These have IP ratings:

- IP65: Protected against water jets and dust.

- IP67/IP68: Fully waterproof, suitable for outdoor or wet environments like boats or car wash stations.

Where Are Metal Push Button Switches Used?

Thanks to their strength and versatility, metal push button switches are widely used across many industries.

Industrial Equipment

They are standard components in control panels, machinery start/stop buttons, and emergency stops. Their durability makes them ideal for factory floors and heavy-duty machines.

Automotive Systems

Modern vehicles use metal push buttons for dash controls, gear selectors, window switches, and even engine start buttons. Electric vehicles also rely on these switches for charging station interfaces.

Marine and RV Applications

Waterproof versions are commonly used on boats, yachts, and recreational vehicles. They provide reliable control even in humid or wet conditions.

Commercial Devices

You’ll find them in vending machines, elevators, ATMs, and security panels where long life and professional appearance are important.

DIY and Home Automation

Enthusiasts and makers often use metal push buttons in custom-built smart home systems, robotics, and interactive projects due to their clean look and solid feel.

Choosing the Right One

Selecting the correct metal push button switch depends on your application. Here are the key factors to consider:

Size

Make sure the switch fits the cutout size in your panel. Most switches are 16mm, 19mm, or 22mm.

Function Type

Decide whether you need a momentary or latching switch. Momentary is good for temporary actions; latching is better for continuous control.

Voltage and Current Rating

Check the voltage and current rating to ensure compatibility with your system. Some switches support up to 20A at 12V or 24V DC.

Environmental Conditions

If the switch will be used outdoors or in wet areas, choose one with a high IP rating like IP67 or IP68.

Illumination

Consider adding LED lighting if you need visual feedback, especially in dimly lit settings.

Mounting Style

Most metal push buttons are mounted using a threaded shaft and nut. Make sure to install them securely to avoid loosening over time.

Metal push button switches are essential components in many modern systems. They combine strength, reliability, and a clean appearance, making them suitable for both industrial and consumer applications.

Whether you’re building a control panel, upgrading a vehicle, or working on a personal electronics project, choosing the right metal push button switch ensures safe and efficient operation.

Understanding the basic types and how to select the best one for your needs helps you make informed decisions and improve the performance of your system.