Meta Description: Discover the critical applications for industrial metal push buttons across manufacturing, transportation, and energy. Learn how these durable switches solve reliability challenges.

Where to Use Industrial Metal Push Buttons for Maximum Reliability

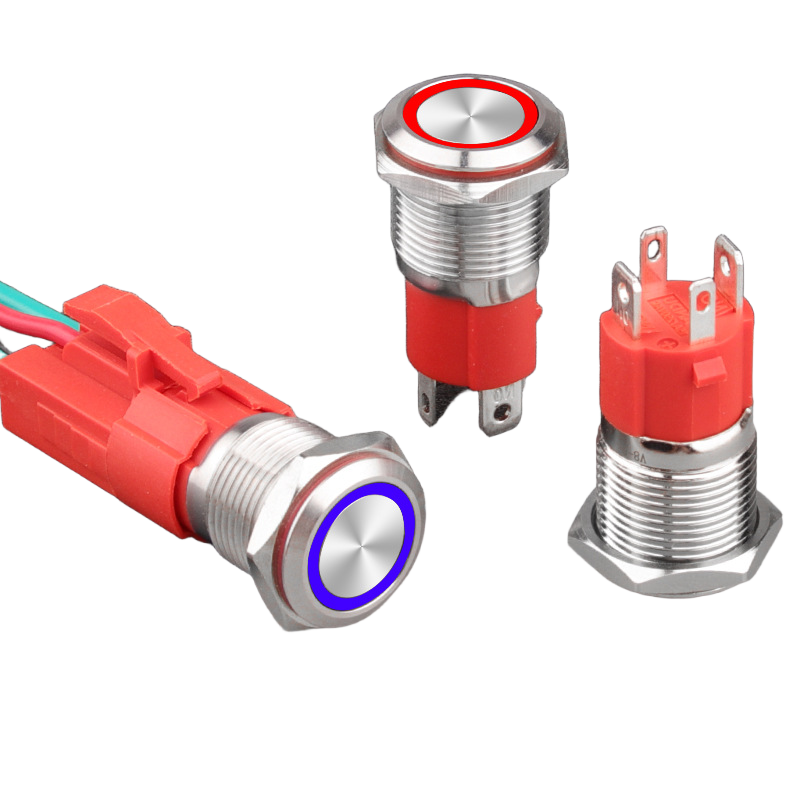

In mission-critical operations, component failure is not an option. Industrial metal push buttons provide the definitive solution for environments where plastic components fall short. These switches are engineered for endurance, offering superior performance where it matters most.

If your projects demand components that can withstand extreme conditions, understanding the core applications for these robust switches is essential.

1. Industrial Machinery and Automation Systems

Manufacturing floors present some of the harshest conditions: constant vibration, airborne contaminants, and frequent human interaction. Standard switches quickly degrade in these settings.

Primary Uses: Emergency stop (E-stop) functions, cycle start/stop controls on CNC equipment, and operator station interfaces on assembly lines.

Why Metal Buttons Excel: Their brass or stainless steel construction resists physical impact and corrosive coolants. With high mechanical life ratings—often exceeding 200,000 cycles—they eliminate downtime from switch failure.

2. Transportation and Heavy-Duty Vehicle Control

From agricultural machinery to logistics vehicles, operational reliability directly impacts productivity. These applications require components that perform despite temperature swings and constant jostling.

Primary Uses: Engine ignition systems in construction equipment, auxiliary control for dump trucks and forklifts, and power control in specialized utility vehicles.

Why Metal Buttons Excel: A wide operating temperature range (-30°C to +85°C) ensures reliable engine starts in both freezing and scorching conditions. Their sealed designs prevent moisture and dust ingress, safeguarding electrical systems.

3. Energy Management and Power Distribution

Systems handling significant electrical loads demand switches with excellent conductivity, high dielectric strength, and long-term contact integrity.

Primary Uses: Control interfaces for electric vehicle charging stations, power-on/off functions in renewable energy inverters, and disconnect controls in electrical cabinets.

Why Metal Buttons Excel: With capabilities like 10A current rating and 2000V AC dielectric strength, they manage high-power applications safely. Silver-plated contacts ensure minimal voltage drop and consistent performance over a long electrical life.

4. ruggedized Outdoor and Infrastructure Equipment

Equipment exposed to the elements needs a first line of defense. The switch is often the most vulnerable point of interaction.

Primary Uses: Power control for outdoor telecommunications cabinets, reset functions for security and monitoring systems, and control panels for maritime and agricultural equipment.

Why Metal Buttons Excel: The metal shell offers inherent protection against UV radiation, corrosion, and physical tampering, ensuring uninterrupted service in remote or exposed locations.

Solving Your Most Demanding Design Challenges

The decision to specify industrial metal push buttons often comes down to three critical factors:

Risk Mitigation: Reducing the high cost of unplanned downtime and repairs.

Safety Compliance: Meeting stringent industry standards for emergency stops and power control.

Lifecycle Value: Achieving a lower total cost of ownership by installing a component that lasts the life of the machine.

Are you designing a system where switch failure would cause operational, financial, or safety risks?

Explore our high-current, waterproof metal push button switches built to deliver unwavering performance. Review detailed specifications or contact our technical team to identify the right component for your application. Let’s build something reliable together. Send email to sales07@socoje.com

Whatsapp:+8617786032435