When an unexpected jam, equipment fault, or worker hazard occurs on an automated production line, every millisecond counts. That’s why choosing the right emergency stop (E-stop) switch isn’t just a “safety checkbox”—it’s a critical line of defense for uptime, worker well-being, and operational reliability. Today, we’re breaking down why the 19mm waterproof metal mushroom head E-stop switch (like our SGJ2E19FZ1 model) is the unsung hero of modern manufacturing lines.

What Makes This 19mm E-Stop Perfect for Automated Lines?

Automated production environments demand switches that can handle constant use, harsh conditions, and instant response—and this switch checks all boxes:

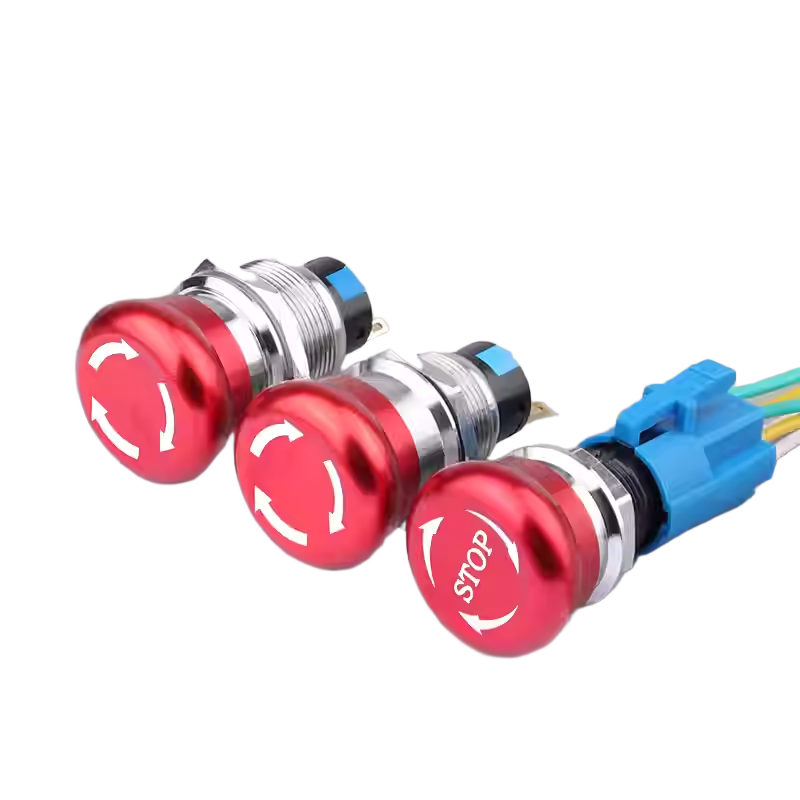

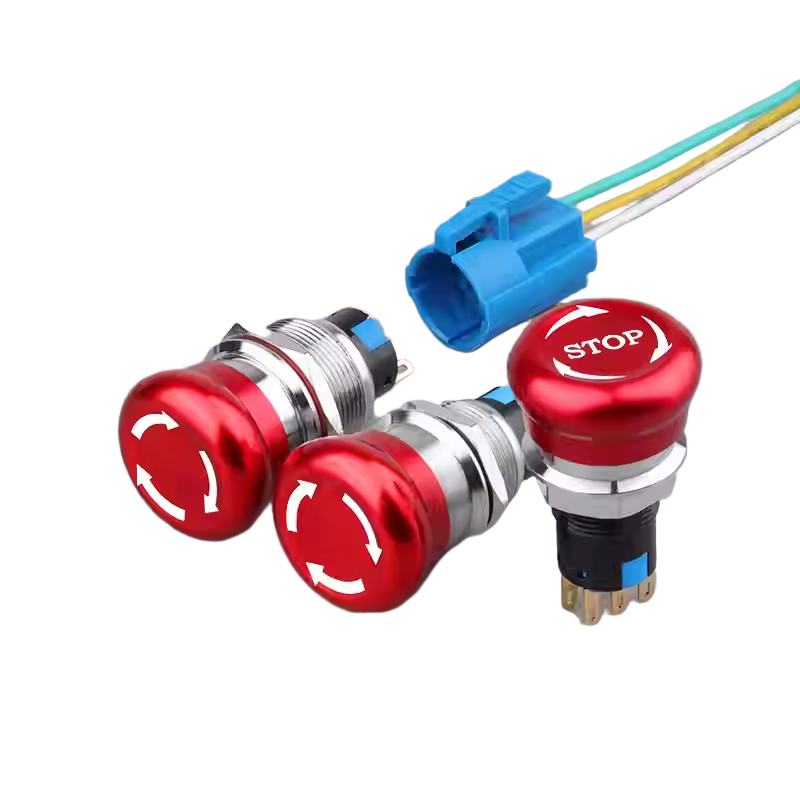

- Mushroom Head Design for Instant Activation

The large, prominent red mushroom head is impossible to miss (even in noisy, fast-paced lines) and allows workers to engage it with a single, firm press—no fumbling for small buttons mid-emergency.

- 19mm Metal Build: Durability for 24/7 Operations

Made of robust metal (with a nickel-brass nut), it resists physical impact, dust, and minor chemical exposure—critical for lines where equipment vibrates or debris is common.

- IP65/IP66/IP67 Waterproof Rating

Spills, cleaning sprays, or humid factory floors won’t short out this switch. Its waterproof seal ensures consistent performance in messy manufacturing environments.

- 3-Pin (SPST) / 6-Pin (SPDT) Configurations

Match it to your line’s control system: 3-pin for simple “stop-only” circuits, or 6-pin for setups that require both emergency stop and auxiliary signaling (e.g., triggering alarms).

Real-World Impact: How This E-Stop Saved a Packaging Line

Last quarter, a food packaging client upgraded their 5-year-old plastic E-stops to this 19mm metal model—and the difference was immediate:

- A worker noticed a misaligned carton jamming the sealing machine; they activated the mushroom head E-stop in 0.2 seconds (vs. 1.1 seconds with the old small-button switch), preventing a $12k conveyor belt damage.

- The IP65 rating stood up to daily washdowns (required for food safety) without a single switch failure—compared to 2-3 plastic switch replacements per month prior.

Key Specs That Matter for Production Managers

For teams vetting components for line upgrades, here’s the technical breakdown that ensures compatibility:

- Electrical Performance: ≤50mΩ contact resistance (minimal signal delay) + 1000VAC dielectric strength (protection against power surges).

- Temperature Range: -30°C to 80°C—works in cold storage packaging lines and heated assembly zones.

- Mounting Fit: 19mm diameter (standard for most control panel cutouts) for easy retrofitting without modifying existing enclosures.

Don’t Compromise on E-Stop Quality for Your Line

When downtime costs $1,000+ per minute (a typical figure for automated lines), cutting corners on safety components is a risky gamble. This 19mm metal mushroom head E-stop isn’t just a switch—it’s a low-cost investment in faster emergency response, longer equipment life, and compliance with OSHA/ISO safety standards.