The Unsung Heroes of Interface

Beyond the sleek touchscreens, the humble metal push button switch remains a cornerstone of reliable human-machine interaction. Found in industrial control panels, medical equipment, transportation, and high-end appliances, these components offer unmatched durability, tactile feedback, and a sense of permanence. This guide dives deep into the world of metal push button switches, exploring their anatomy, types, materials, and fundamental operating principles.

1. Anatomy of a Metal Push Button Switch: More Than Just a Button

* Button Cap/Actuator: The visible, user-pressed metal component (Stainless Steel, Brass, Aluminum). Shapes: Flush, Extended, Domed, Flat. Surface finishes: Brushed, Polished, Powder-Coated, Anti-Bacterial.

* Switch Body/Housing: The main metal enclosure protecting internal mechanisms. Provides mounting stability and environmental sealing. Materials often match the cap or use zinc alloy.

* Contact Mechanism: The heart of the switch. Types:

* Tactile (Momentary): Provides a physical “click,” returns automatically (e.g., keyboard keys, reset buttons).

* Latching (Maintained): Stays in position after press (on/off), requires another press to release (e.g., power switches).

* Alternate Action: First press on, second press off (like a classic ballpoint pen).

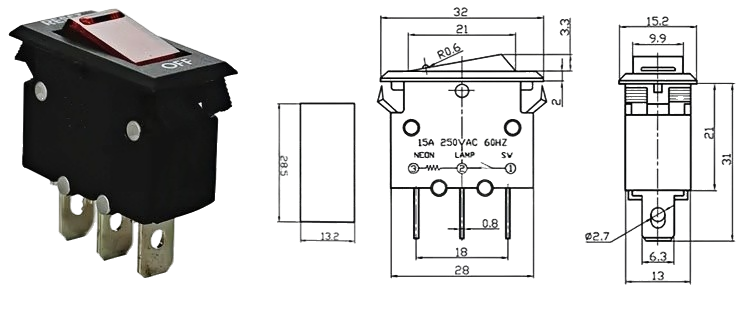

* Terminals/Connectors: Points for electrical connection (Solder Lugs, Quick Connect, Screw Terminals, PCB Pins).

* Internal Spring: Provides the return force for momentary switches and the tactile feel.

* Seals/Gaskets: Critical for environmental protection (O-rings, silicone gaskets) enabling IP ratings.

2. Why Metal? Key Advantages Over Plastic

* Extreme Durability & Longevity: Resists impact, crushing forces, and wear far better than plastic. Lifespans often exceed 1,000,000 cycles.

* Superior Environmental Resistance: Impervious to UV degradation, solvents, chemicals, oils, and extreme temperatures (-40°C to +120°C common).

* Enhanced Safety & Security: Fire resistance, higher dielectric strength, and resistance to vandalism/tampering.

* Professional Aesthetics & Feel: Projects quality, robustness, and precision. Offers satisfying tactile feedback with a premium weight.

* Hygiene: Non-porous metal surfaces (especially stainless steel) are easy to clean and sterilize, crucial for medical and food processing.

3. Core Switching Mechanisms Explained

* Snap-Action (Microswitch Based): Utilizes a spring-loaded lever inside a microswitch. Offers crisp, reliable actuation with minimal contact bounce. Common for industrial applications.

* Direct Plunger: The button cap directly presses on the moving contact. Simpler design, can offer a smoother feel.

* Rocker Mechanism (for Latching): Internal mechanism that physically locks the button in position until pressed again.

* Contact Materials: Silver Alloy (AgNi, AgCdO, AgSnO2), Gold Plating. Choice affects current rating, arcing resistance, and longevity.

4. Electrical Specifications: Making the Right Connection

* Voltage Rating (AC/DC): The maximum voltage the switch can safely handle (e.g., 12VDC, 120VAC, 250VAC).

* Current Rating: The maximum current the contacts can carry reliably (e.g., 1A, 3A, 5A, 10A, 20A). Resistive vs. Inductive loads matter.

* Contact Configuration:

* SPST (Single Pole, Single Throw): Simple On/Off (Momentary or Latching).

* SPDT (Single Pole, Double Throw): Three terminals (Common, Normally Open, Normally Closed). Can act as a selector.

* DPST/DPDT: For controlling two independent circuits simultaneously.

* Insulation Resistance & Dielectric Strength: Measures isolation between contacts and housing (critical for safety).

5. Understanding Environmental Protection (IP Ratings)

* IP Code (Ingress Protection): Essential for specifying dust/water resistance.

* First Digit (Solids): 6 = Dust-tight.

* Second Digit (Liquids): 5 = Low-pressure water jets; 6 = Powerful water jets; 7 = Immersion up to 1m; 8 = Continuous immersion >1m.

* Sealing Technologies: O-rings (static/dynamic), molded gaskets, ultrasonic welding, potting compounds. Material compatibility (e.g., EPDM, Silicone, Viton) is crucial for chemical resistance.

6. Illumination Options: Signaling Status

* LED Integration: Most common (low power, long life). Requires current-limiting resistors. Types: Through-hole, SMD.

* Lamp Holders: For incandescent bulbs (less common now).

* Light Pipes: Transmit light from an internal LED/component to the button cap.

* Symbols & Legends: Engraved/filled, laser-etched, or printed onto the metal cap. Backlighting options.

The Foundation of Robust Control

Metal push button switches provide a critical blend of physical resilience, electrical reliability, and professional aesthetics unmatched by plastic alternatives. Understanding their core components, materials, mechanisms, electrical specs, and environmental protection capabilities is essential for selecting the right switch for demanding applications where failure is not an option. Their fundamental role in safe and reliable control interfaces ensures their continued relevance in an increasingly digital world.