In a world dominated by touchscreens and voice-activated systems, the humble rotary switch might seem like an anachronism. Yet, this mechanical interface remains a cornerstone of modern technology, quietly driving everything from aircraft controls to smart home devices. Its enduring relevance lies in its ability to merge tactile feedback with functional precision, offering a level of control that abstract digital interfaces often lack. This blog explores how rotary switches have evolved beyond their mechanical roots to become indispensable in industries where reliability, customization, and user experience are paramount.

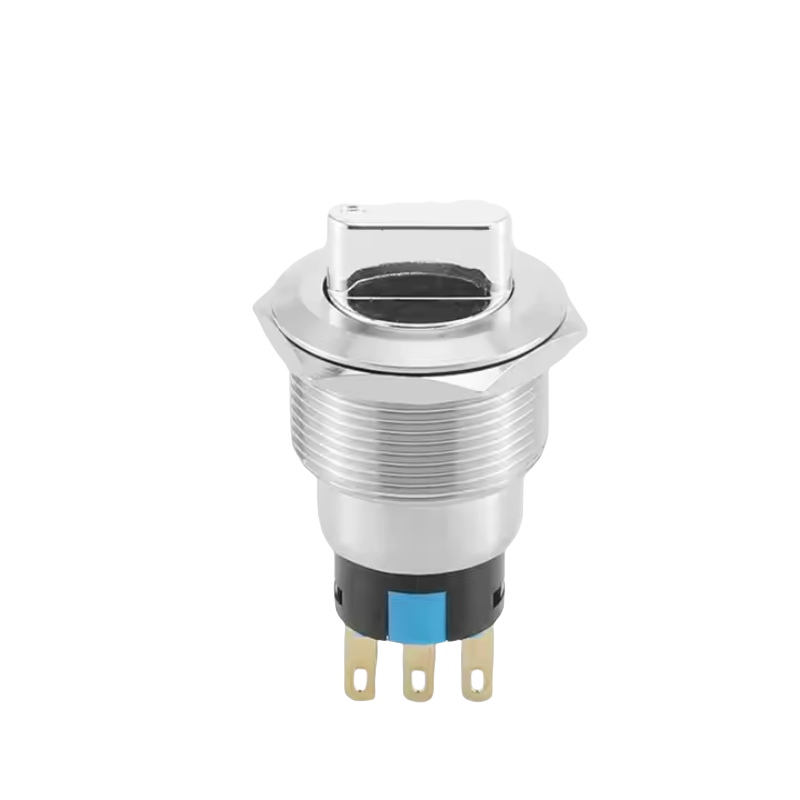

The journey of the rotary switch began in the early 20th century as a solution to the limitations of toggle switches. By rotating a knob to align internal contacts with predefined positions, it enabled users to select from multiple settings—volume levels, channel selections, or industrial parameters—with a single motion. The simplicity of this design made it durable and reliable, qualities that cemented its role in radios, televisions, and machinery. However, the mechanical era had its constraints. Wear and tear, susceptibility to environmental factors, and the inability to integrate with digital systems limited its potential.

The 1980s and 1990s marked a turning point as rotary switches began incorporating digital encoders—components that convert mechanical rotation into digital signals. This innovation allowed them to interface with microprocessors, enabling programmable functionality. A single knob could now adjust brightness, contrast, and color temperature on a display, or control the speed of a CNC machine. This shift from analog to digital opened new possibilities in industries like audio engineering, where precision is critical. High-end mixing consoles and professional cameras adopted these switches for their ability to handle complex workflows, while industrial automation leveraged them for real-time parameter adjustments.

Today, rotary switches are no longer passive components but active participants in smart ecosystems. In the 2010s and 2020s, advancements in IoT (Internet of Things) and AI transformed them into intelligent interfaces. Consider a smart home thermostat: a physical knob allows users to adjust temperature settings while syncing with mobile apps or voice assistants. The tactile feedback of the knob complements touch-screen interfaces, reducing user fatigue and enhancing intuitive control. Similarly, in industrial IoT, rotary switches with built-in sensors transmit real-time data about machine performance to centralized dashboards, enabling predictive maintenance and efficiency optimization.

Artificial intelligence has further elevated rotary switches into adaptive interfaces. For example, a smart lighting system might use AI to analyze ambient light levels and automatically adjust brightness via a rotary switch. When combined with voice recognition or gesture detection, these switches create hybrid interfaces that prioritize seamless user experiences. In automotive applications, luxury cars like Tesla’s Model S use central rotary controllers to manage navigation and media. Some automakers even integrate haptic feedback—subtle vibrations that confirm selections—reducing driver distractions and improving safety.

Beyond technical integration, rotary switches play a unique role in design aesthetics and user psychology. Their physical form engages multiple senses: the resistance of the knob provides tactile confirmation, the “click” of contact alignment offers auditory reassurance, and the visual alignment of the knob with labeled positions reinforces user understanding. This multisensory interaction fosters a sense of control that abstract interfaces like touchscreens often lack. For instance, pilots adjusting an aircraft’s altitude with a rotary switch feel a direct connection to the machine, whereas a touchscreen might feel detached.

In industries where precision is non-negotiable, rotary switches remain irreplaceable. Surgical robots and diagnostic machines rely on them to adjust parameters like speed or pressure, often with sterilizable coatings to meet hygiene standards. In aerospace, cockpit controls and satellite ground stations use these switches for critical functions where even minor errors can have catastrophic consequences. The reliability of their mechanical design ensures consistent performance under extreme conditions.

Emerging trends are pushing rotary switches into uncharted territory. Researchers are experimenting with holographic interfaces that project 3D knobs into the air, eliminating physical components while retaining tactile-like interactions. Biometric integration is another frontier: future switches may incorporate fingerprint or vein recognition for secure access to sensitive systems. Meanwhile, sustainability efforts are reshaping manufacturing. Low-power encoders extend battery life in portable devices, while eco-friendly materials like recycled plastics and aluminum alloys reduce environmental impact.

Despite their evolution, challenges persist. Miniaturization efforts must balance reduced size with durability, and interoperability with diverse IoT protocols remains a hurdle. However, the global rotary switch market is projected to grow at a CAGR of 5.2% from 2025 to 2030, driven by demand in smart home devices, industrial automation, and healthcare. As industries embrace sustainability and customization, the rotary switch will continue to adapt, proving that sometimes the best solutions are the ones that blend tradition with innovation.

From their mechanical origins to their role in smart ecosystems, rotary switches exemplify the power of human ingenuity. Whether in a home, factory, or hospital, they remind us that the best technology is not just functional—it is intuitive, reliable, and deeply human.