We tap, we press, we click. Our digital world is saturated with ephemeral interactions – touchscreens, capacitive sensors, voice commands. Yet, in the heart of critical machinery, within the cockpits of aircraft, on the control panels of life-saving medical devices, and even in the satisfying thunk of premium audio gear, reigns a stalwart champion of tactile certainty: the metal push button switch. More than just a simple electrical interruptor, it’s a profound intersection of engineering, psychology, material science, and even philosophy. This isn’t just a component; it’s a tactile covenant between human intention and mechanical action.

Beyond the Click: The Materiality of Trust

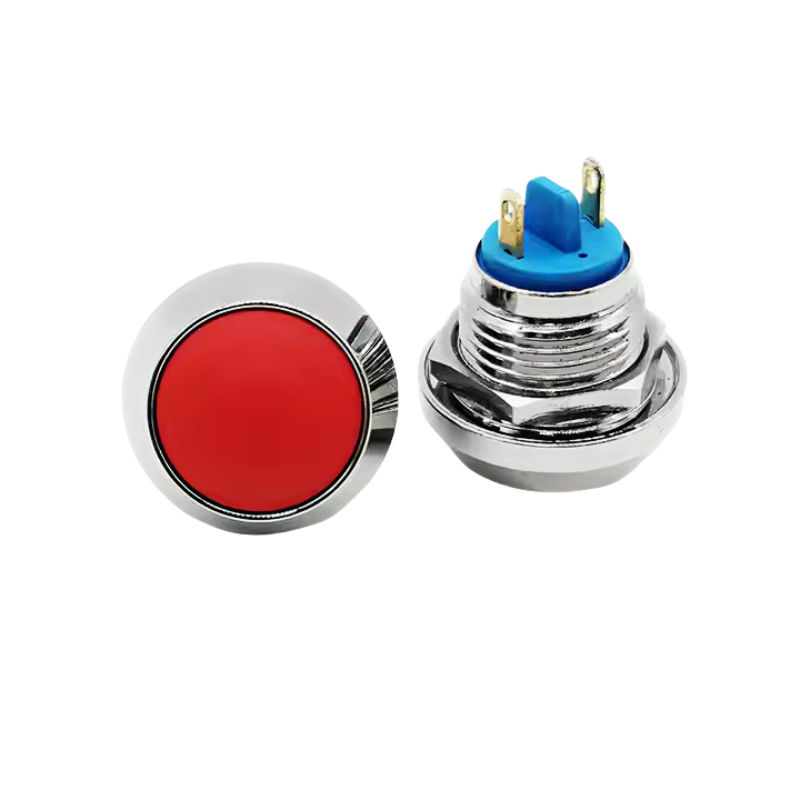

Why metal? In an age obsessed with cost-cutting polymers, the choice of brass, stainless steel, aluminum, or zinc alloy speaks volumes. It’s a declaration of intent and permanence.

The Weight of Responsibility: A metal button has inherent mass. Pressing it requires deliberate, conscious force. This isn’t accidental activation. In environments where a misplaced command could have catastrophic consequences – launching a missile, initiating an emergency stop (E-stop), shutting down a reactor – the physical resistance and positive feedback of metal are non-negotiable safeguards. The weight conveys the gravity of the action it controls.

Endurance Embodied: Metal resists. It laughs off abrasion from countless presses, shrugs off chemical splashes in industrial settings, and endures temperature extremes that would warp or crack plastic. Its mechanical life – often rated in hundreds of thousands, even millions of cycles – is orders of magnitude beyond most plastic counterparts. This longevity isn’t just about cost savings; it’s about reliability over decades, a promise that the switch will be there when needed, always.

The Aesthetics of Authority: Polished stainless steel gleams with sterile precision in a lab. Anodized aluminum in matte black exudes understated control in high-end audio. Heavy, knurled brass evokes rugged dependability in marine applications. The material and finish communicate the switch’s purpose and the quality of the system it governs. It feels substantial, fostering an unconscious trust in the machine it commands. It’s the difference between a flimsy plastic toy remote and the solid controls of a vintage Leica camera.

Thermal & Electrical Conductivity: While often insulated, the metal housing acts as a superior heat sink, protecting internal contacts. In high-current applications, robust metal terminals ensure efficient power transfer and minimize resistance heating at critical connection points. Metal housings also provide inherent electromagnetic shielding (EMI/RFI), crucial in sensitive electronic environments.

The Symphony of Tactility: Engineering the “Feel”

The magic of a truly great metal push button switch lies not just in its construction, but in its haptics – the science of touch and feedback. This is where engineering becomes artistry.

The “Click”: That satisfying, audible snap isn’t just sound; it’s tactile confirmation. Internally, mechanisms like spring-loaded leaf contacts, dome switches (often metal themselves), or precise slider assemblies create a distinct over-center action. This provides a crisp, unambiguous break or make point. The user feels and hears the exact moment the circuit changes state. This binary feedback is irreplaceable for critical functions – you know you’ve pressed “stop.”

Force Curve: The journey of the press matters. The initial resistance (pre-travel force), the distinct breakpoint force where the action happens, the subsequent travel (overtravel), and the reset force all combine to create a unique fingerprint. A heavy, slow-rising curve feels deliberate and powerful (E-stop). A light, sharp break feels fast and responsive (data entry). Engineers meticulously tune this curve for the intended use and user expectation.

Travel & Overtravel: The physical distance the button travels (stroke) and the additional movement after actuation (overtravel) absorb shock and ensure the contacts are fully engaged, even with imperfect presses. Metal bodies provide the rigidity needed to maintain precise tolerances for consistent travel over the switch’s lifetime.

Seals & Protection: Metal housings provide the robust foundation for effective sealing. Integral O-rings (often silicone or Viton) compressed between the button stem and housing create ingress protection ratings like IP67 (dust-tight, withstands immersion) or IP69K (resists high-pressure, high-temperature washdowns). This is vital for food processing, outdoor equipment, marine use, and harsh industrial environments where water, dust, oils, or cleaning agents are constant threats.

The Psychology of the Press: Why Metal Commands Confidence

Our relationship with metal buttons is deeply psychological. They tap into primal senses and learned experiences.

Affordance & Feedback: A well-designed metal button looks pressable. Its form (often concave or with clear edges) signals its function. The immediate, unambiguous tactile and auditory feedback upon pressing provides closure. The action is complete; the command has been issued. There’s no ambiguity, no wondering “Did it register?” like with a mushy or silent button.

Perceived Durability & Quality: Heft equals strength in the human psyche. A solid metal button feels expensive, reliable, and built to last. It elevates the perceived quality of the entire device. Using it feels like interacting with something significant, not disposable. This builds user trust and satisfaction.

Reducing Cognitive Load: In high-stress or complex situations (operating heavy machinery, emergency response, piloting), clear, distinct feedback is paramount. Metal buttons, with their defined actuation point and feedback, allow operators to focus on the task, not on deciphering interface cues. Muscle memory develops rapidly.

The Ritualistic Element: Pressing a substantial metal button can feel ceremonial. Think of launching a spacecraft, powering up a massive generator, or committing a critical database transaction. The deliberate physical act reinforces the significance of the event. It’s a tangible connection point in an increasingly virtual world.

Evolution & Innovation: Not Your Grandfather’s Switch

Metal push buttons aren’t relics; they’re constantly evolving:

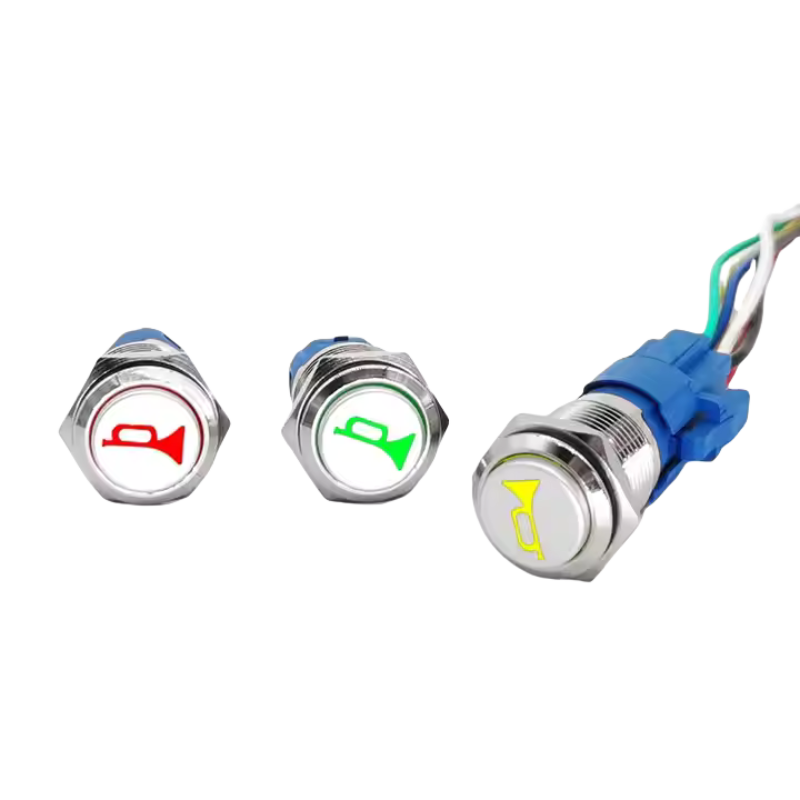

Illumination Integration: Modern switches seamlessly incorporate high-brightness, long-life LEDs (SMD or through-lens) within the metal housing. Colored legends (engraved and filled, or coated) provide clear status indication (red for stop, green for go, amber for warning). Light pipes ensure even distribution. Sealing around the light source remains a critical engineering challenge met with precision gasketing and potting.

Customization & Branding: CNC machining allows for intricate shapes, custom engravings, and unique surface finishes (brushed, bead-blasted, PVD coated) that align with brand identity or specific aesthetic requirements. A switch becomes a design element.

Enhanced Sealing Technologies: New elastomer compounds and sealing geometries push IP ratings higher, enabling use in even more extreme environments. Hermetically sealed versions exist for vacuum or explosive atmospheres (ATEX/IECEx).

Hybrid Designs: Combining metal bodies (for durability and feel) with advanced internal contact materials (gold plating for low signal, silver alloys for power) or even integrating microelectronic elements (like capacitive sensing for multi-function) while retaining the core mechanical actuation.

Specialized Actuators: Mushroom heads for emergency stops, guarded actuators to prevent accidental presses, key-lock actuators for security, and backlit symbols for low-light conditions.

Beyond Industry: The Ubiquitous Metal Click

While industrial controls are their fortress, metal push buttons enhance our daily lives in subtle, satisfying ways:

High-Fidelity Audio: Amplifiers, DACs, and preamps use them for source selection or power – their solid feel and lack of microphonics (resonance affecting sound) are prized by audiophiles. The “thunk” signifies quality.

Automotive Interiors: Premium cars use metal switches for window controls, ignition start/stop, and drive mode selectors, conveying luxury and robustness.

Smart Home & Prosumer Gear: High-end espresso machines, kitchen appliances, studio equipment, and even premium computer peripherals (keyboards, DACs) leverage metal buttons for their durability, aesthetics, and superior tactile feel.

Retro & Bespoke Electronics: The resurgence of vintage aesthetics and the maker movement see metal switches used in custom builds, synthesizers, and boutique guitar pedals for their look and feel.

Medical Devices: Reliability and cleanability make sealed metal buttons essential for surgical equipment, diagnostic machines, and patient monitors where failure is not an option.

The Ethical Switch: Sustainability and Responsibility

The choice of metal also carries implications. Responsible sourcing of materials, energy efficiency in manufacturing, and designing for extreme longevity (reducing e-waste) are increasingly important. A metal switch built to last 20 years is inherently more sustainable than multiple plastic replacements. Recyclability of the metals used (especially aluminum and stainless steel) is another key advantage. Choosing quality metal switches is, in part, an environmental statement.

In a world racing towards the intangible, the metal push button switch stands as a resolute testament to the power of physical connection. It is an engineered object that speaks directly to our senses of touch, hearing, and even sight. Its materiality conveys strength, permanence, and trust. Its carefully crafted tactile feedback provides unambiguous certainty. Its robust construction ensures unwavering reliability under duress.

It is more than just a switch; it’s a tactile covenant. It promises that when you press it, with deliberate force, feeling that distinct click travel through your finger, hearing the confirming snap, something definite will happen in the physical world. It bridges the gap between human intention and mechanical consequence with unmatched authority and grace. From controlling the mightiest industrial machines to adding a moment of satisfying precision to your morning coffee ritual, the metal push button switch remains an unsung hero of the engineered world – a small, solid bastion of reliability and tangible feedback in an increasingly virtual landscape. It is a reminder that sometimes, the most profound interactions are not swipes on glass, but the decisive press of cold, hard, beautifully engineered metal.