Introduction: The Unsung Heroes of Interface

Beyond the sleek touchscreens, the humble metal push button switch remains a cornerstone of reliable human-machine interaction. Found in industrial control panels, medical equipment, transportation, and high-end appliances, these components offer unmatched durability, tactile feedback, and a sense of permanence. This guide dives deep into the world of metal push button switches, exploring their anatomy, types, materials, and fundamental operating principles.

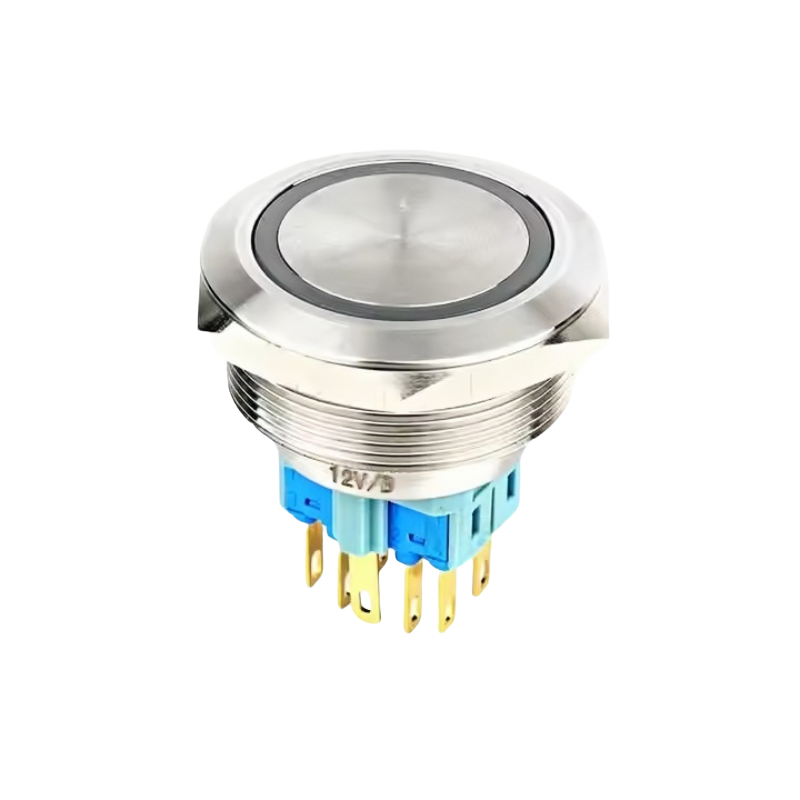

1. Anatomy of a Metal Push Button Switch: More Than Just a Button

* Button Cap/Actuator: The visible, user-pressed metal component (Stainless Steel, Brass, Aluminum). Shapes: Flush, Extended, Domed, Flat. Surface finishes: Brushed, Polished, Powder-Coated, Anti-Bacterial.

* Switch Body/Housing: The main metal enclosure protecting internal mechanisms. Provides mounting stability and environmental sealing. Materials often match the cap or use zinc alloy.

* Contact Mechanism: The heart of the switch. Types:

* Tactile (Momentary): Provides a physical “click,” returns automatically (e.g., keyboard keys, reset buttons).

* Latching (Maintained): Stays in position after press (on/off), requires another press to release (e.g., power switches).

* Alternate Action: First press on, second press off (like a classic ballpoint pen).

* Terminals/Connectors: Points for electrical connection (Solder Lugs, Quick Connect, Screw Terminals, PCB Pins).

* Internal Spring: Provides the return force for momentary switches and the tactile feel.

* Seals/Gaskets: Critical for environmental protection (O-rings, silicone gaskets) enabling IP ratings.

2. Why Metal? Key Advantages Over Plastic

* Extreme Durability & Longevity: Resists impact, crushing forces, and wear far better than plastic. Lifespans often exceed 1,000,000 cycles.

* Superior Environmental Resistance: Impervious to UV degradation, solvents, chemicals, oils, and extreme temperatures (-40°C to +120°C common).

* Enhanced Safety & Security: Fire resistance, higher dielectric strength, and resistance to vandalism/tampering.

* Professional Aesthetics & Feel: Projects quality, robustness, and precision. Offers satisfying tactile feedback with a premium weight.

* Hygiene: Non-porous metal surfaces (especially stainless steel) are easy to clean and sterilize, crucial for medical and food processing.

3. Core Switching Mechanisms Explained

* Snap-Action (Microswitch Based): Utilizes a spring-loaded lever inside a microswitch. Offers crisp, reliable actuation with minimal contact bounce. Common for industrial applications.

* Direct Plunger: The button cap directly presses on the moving contact. Simpler design, can offer a smoother feel.

* Rocker Mechanism (for Latching): Internal mechanism that physically locks the button in position until pressed again.

* Contact Materials: Silver Alloy (AgNi, AgCdO, AgSnO2), Gold Plating. Choice affects current rating, arcing resistance, and longevity.

4. Electrical Specifications: Making the Right Connection

* Voltage Rating (AC/DC): The maximum voltage the switch can safely handle (e.g., 12VDC, 120VAC, 250VAC).

* Current Rating: The maximum current the contacts can carry reliably (e.g., 1A, 3A, 5A, 10A, 20A). Resistive vs. Inductive loads matter.

* Contact Configuration:

* SPST (Single Pole, Single Throw): Simple On/Off (Momentary or Latching).

* SPDT (Single Pole, Double Throw): Three terminals (Common, Normally Open, Normally Closed). Can act as a selector.

* DPST/DPDT: For controlling two independent circuits simultaneously.

* Insulation Resistance & Dielectric Strength: Measures isolation between contacts and housing (critical for safety).

5. Understanding Environmental Protection (IP Ratings)

* IP Code (Ingress Protection): Essential for specifying dust/water resistance.

* First Digit (Solids): 6 = Dust-tight.

* Second Digit (Liquids): 5 = Low-pressure water jets; 6 = Powerful water jets; 7 = Immersion up to 1m; 8 = Continuous immersion >1m.

* Sealing Technologies: O-rings (static/dynamic), molded gaskets, ultrasonic welding, potting compounds. Material compatibility (e.g., EPDM, Silicone, Viton) is crucial for chemical resistance.

6. Illumination Options: Signaling Status

* LED Integration: Most common (low power, long life). Requires current-limiting resistors. Types: Through-hole, SMD.

* Lamp Holders: For incandescent bulbs (less common now).

* Light Pipes: Transmit light from an internal LED/component to the button cap.

* Symbols & Legends: Engraved/filled, laser-etched, or printed onto the metal cap. Backlighting options.