The Silent Enabler of Our Everyday World

We interact with switches every day — turning on lights, starting appliances, operating elevators, and even unlocking our phones. Yet, few of us ever stop to think about the mechanics behind these actions. One of the most reliable tools in this invisible world of interaction is the metal push button switch.

It may appear simple, but this small device is engineered for precision, durability, and adaptability. In this article, we’ll dive deep into the world of metal push button switches, exploring their structure, benefits, applications, and how they continue to shape the way we engage with technology.

Understanding the Basics: What Is a Metal Push Button Switch?

A metal push button switch is a manually operated electrical component that allows users to open or close a circuit by pressing a button. Unlike toggle switches or rotary dials, push buttons provide a direct, intuitive form of input.

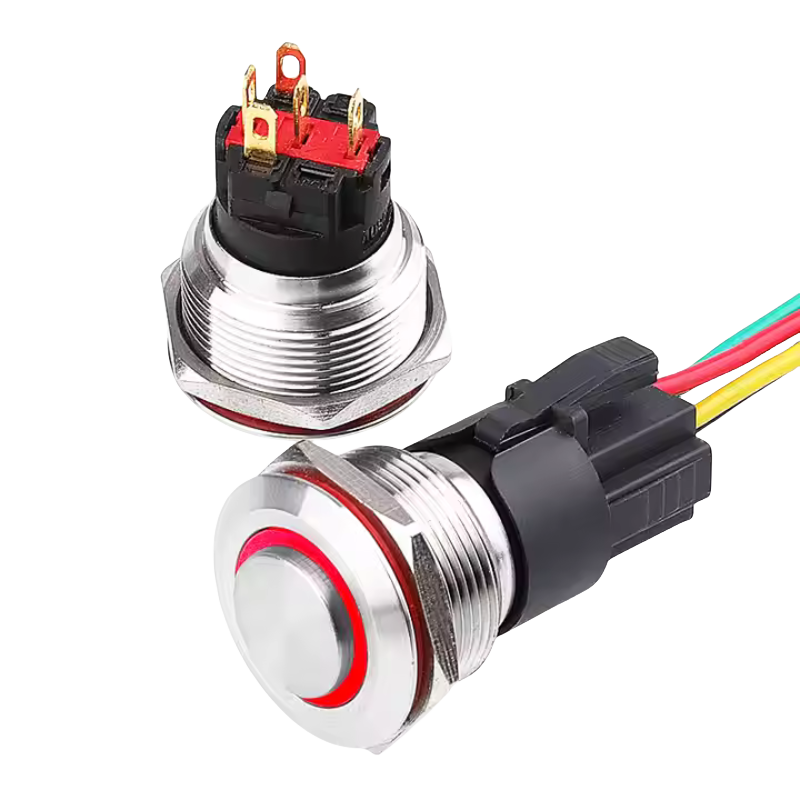

Most metal push buttons consist of:

- Actuator (Button Cap): Made from stainless steel, brass, or aluminum.

- Contact Terminals: Connect the switch to the electrical circuit.

- Spring Mechanism: Ensures the button returns to its original position after being pressed.

- Optional Features: Such as LED indicators, waterproofing, and self-locking mechanisms.

They come in standard sizes like 12mm, 16mm, 19mm, 22mm, and 30mm, each suited for different installation needs and environments.

Why Metal Stands Out

Compared to plastic or rubber alternatives, metal offers several key advantages:

1. Longevity

Metal push buttons are built to last. With proper construction, they can endure millions of operations without degradation — making them ideal for industrial and commercial use.

2. Resistance to Harsh Conditions

Many metal push buttons are rated for IP65, IP67, or even IP69K, meaning they can survive exposure to dust, water, and high-pressure cleaning. This makes them perfect for use in kitchens, factories, hospitals, and outdoors.

3. Premium Look and Feel

Metal conveys a sense of quality and elegance. Whether brushed, polished, or colored, metal buttons elevate the design of any device — from luxury kitchen appliances to high-end automotive interiors.

4. Clear Tactile Feedback

A well-designed metal push button provides instant haptic feedback. You don’t just see or hear the switch activate — you feel it, ensuring confidence in operation.

Varieties of Metal Push Button Switches

Metal push button switches come in several functional and visual variations:

Momentary vs. Self-Locking (Latching)

- Momentary: Only active while pressed (e.g., doorbells).

- Self-Locking: Remains activated until pressed again (e.g., power switches).

Illuminated vs. Non-Illuminated

- Illuminated: Includes LED lighting for visibility in low-light conditions.

- Non-Illuminated: Minimalist design for applications where light isn’t needed.

Contact Types

- SPST: Basic on/off switch.

- SPDT/DPDT: Allows for more complex circuit routing.

Applications Across Industries

Metal push button switches are versatile enough to be used in nearly every field. Here are some notable examples:

Industrial Automation

Control panels, emergency stops, and production line interfaces rely on robust metal push buttons to ensure safe and efficient operation.

Automotive

High-end vehicles increasingly use metal push buttons for features like gear selection, HVAC controls, and infotainment navigation.

Consumer Electronics

Smart home hubs, premium audio equipment, and professional-grade kitchen appliances often incorporate metal buttons for their tactile and aesthetic qualities.

Healthcare

Medical devices such as patient monitors, diagnostic tools, and sterilization equipment require switches that are both hygienic and durable — qualities metal delivers.

Public Infrastructure

Elevators, ticket machines, and ATMs use metal push buttons because they stand up to constant use and abuse.

Choosing the Right Switch for Your Needs

Selecting the right metal push button switch involves considering several key factors:

Size Compatibility

Ensure the switch fits the mounting hole in your panel (e.g., 12mm, 16mm, 22mm).

Electrical Ratings

Check the maximum voltage and current capacity to avoid overloading the switch.

Environmental Protection

Choose a switch with an appropriate IP rating if it will be exposed to moisture, dust, or chemicals.

Functionality

Decide whether you need a momentary or latching switch, and what type of contact configuration best suits your circuit.

Design Preferences

Consider color, finish, and illumination options to match your product’s visual identity.

The Future of Metal Push Button Switches

Even as technology evolves, metal push button switches continue to innovate:

Smarter Integration

IoT-enabled switches can communicate with cloud platforms, offering remote monitoring and diagnostics.

Enhanced User Experience

Haptic feedback, customizable LED lighting, and responsive actuation make modern switches more interactive and engaging.

Sustainability

Manufacturers are exploring eco-friendly materials, recyclable metals, and energy-efficient LED options.

Miniaturization

Advances in manufacturing allow for smaller, thinner switches that can fit into compact and wearable devices.

Final Thoughts

The metal push button switch may be small, but its impact is immense. It bridges the gap between humans and machines, offering a tangible, reliable means of control in an increasingly digital world.

Whether in a factory, a hospital, or your living room, the metal push button switch remains a quiet yet essential enabler of modern life. And as technology continues to evolve, so too will the design and capabilities of this enduring component.

Abhilash Reddy

Required the spec